Cementitious tile adhesives and chemometrics: case studies

Chemometrics is the chemical discipline that uses mathematical and statistical methods to optimize experimental designs by maximizing the quality of the information obtained. It has demonstrated its flexibility and adaptability to formulation science and has been applied in a previous work to the formulation of cementitious tile adhesives. This paper will analyze the attempt to produce several experimental designs and the models dedicated to the understanding of the mechanisms that regulate the behaviour of different aspects of this family of dry-mix mortars, such as mechanical performance, deformability and dust generation.

1 Introduction

Cementitious tile adhesives are dry-mix building materials. Their formulations are usually evaluated in accordance with standards [1] that provide a considerable range of tests covering different aspects of these mortars, such as adhesion strength, flexibility and workability. This situation reflects the intrinsically multivariant nature of the testing of these materials. A previous work [2] has demonstrated the effectiveness of chemometrics for devising strategies for formulating adhesive mortars. In particular, the Principal Components Analysis [3] approach can be used to...

1 Introduction

Cementitious tile adhesives are dry-mix building materials. Their formulations are usually evaluated in accordance with standards [1] that provide a considerable range of tests covering different aspects of these mortars, such as adhesion strength, flexibility and workability. This situation reflects the intrinsically multivariant nature of the testing of these materials. A previous work [2] has demonstrated the effectiveness of chemometrics for devising strategies for formulating adhesive mortars. In particular, the Principal Components Analysis [3] approach can be used to extract the maximum amount of information from tables of complex results.

After a general investigation of the properties of cementitious tile adhesives [2] this paper discusses different experimental designs [4] and models. It deals with a specific model for polymer-free adhesives (“C1” in accordance with EN 12004), a model dedicated to the investigation of the deformability behaviour of adhesives and the modelling of the dust production mechanisms of these mortars.

2 Materials

Several of the cementitious tile adhesives formulation variables are taken into account in this work:

1) Ordinary Portland cement (CEM I 52.5R grey, 20 % – 40 %)

2) Cellulose ether (0.25 % – 0.45 %)

3) Modifications of cellulose ether

(non-modified and highly modified)

4) Set and strength development accelerator

(calcium formate, 0.3 % – 0.8 %)

5) Redispersible polymeric powder (0 % – 10 %)

6) Fine calcium carbonate (< 100 µm, 0 % – 20 %)

7) Coarse calcium carbonate (0-600 µm, 0 % – 20 %)

8) Cellulose fibres (0 – 2 %)

Portland cement (the real basis of cementitious tile adhesives) is the only component present in all the models treated in this paper, while the other components are considered in relation to their importance in the different models discussed. In all cases the rest of the formulation consists of silica sand with a standard particle size distribution of 100 – 400 µm.

3 Experimental methods

3.1 Evaluation of the properties of

cementitious tile adhesives

In the “C1 adhesives” model the Brookfield viscosity has been used as the reference for setting the mixing water for all the formulations investigated. The mix ratio is selected so that the viscos-ity of the wet mortar is around 500000 mPa∙s. This then controls all the fresh mortar properties of the adhesive (specific gravity, adjustability time and tile slip).

The pull-off adhesion resistances are evaluated for each formulation in accordance with EN 12004 [1]: open time after 5, 20 and 30 minutes, initial adhesion (28 days under standard conditions), adhesion after ageing at 70°C, after water immersion and after freeze-thaw cycles.

Deformability tests have not been introduced for the “C1 model” as this type of mortar does not contain redispersible polymer and has an intrinsically low flexibility. In any case, a standalone model dedicated to adhesive deformability has been developed, again in agreement with the EN 12004 test methods.

3.2 Evaluation of the dustiness

of cement-based tile adhesives

The dustiness of cementitious tile adhesives is a practical issue in the real world that occurs every time a bag of product is poured into a bucket. This property has been evaluated with an AnaTec DustMon L machine.

The standard dust measurement procedure consists of dropping a fixed amount of cementitious product into an 80 cm tube so that a cloud of dust is generated inside a test chamber. The measurement is taken with a laser light detector that transforms the amount of occluded light into a “dust index”. These values (%) are recorded immediately after generation of the dust cloud and after 30 seconds from the impact. The so-called “Dust Index” is the defined as the sum of these two numbers and can be considered as an indicator of air quality during the use of cementitious products.

3.3 Data analysis software

Principal Components Analysis [3] has been carried out on the raw data using CAT (Chemometric Agile Tool) [5], the Chemometrics software based on R-language distributed by the Italian Chemometrics Group. The elaboration of the experimental designs, the definition of the models and their graphical representation were performed using BasiCAT [6], the Microsoft Visual Basic© free software developed at Mapei laboratories. This permits evaluation of the model accuracy, identification of the significance of the coefficients obtained and an intuitive and flexible prediction function for multiple responses.

4 Experimental models and raw results

4.1 C1 tile adhesive model

This Full-Factorial Central Composite Design [4] model, initially created to understand the behaviour of set accelerating additives, includes the following formulation variables:

1) Ordinary Portland cement (20 % – 35 %)

2) Cellulose ether (0.25 % – 0.45 %)

3) Modified cellulose ether (non-modified, highly modified for strong sag resistance and a 50/50 mixture of the two)

4) Set and strength development accelerator (calcium formate, 0.3 % – 0.8 %)

The experimental plan of this design is shown in Table 1 while the raw results obtained are given in Table 2.

4.2 Deformability model for tile adhesives

This Full-Factorial Central Composite Design model was created for improved investigation of the behaviour of cementitious tile adhesives in the deformability test. It includes three formulation variables that are responsible for the flexibility of mortars:

1) Ordinary Portland cement (20 % – 40 %)

2) Redispersible polymeric powder (0 % – 6 %)

3) Cellulose fibres (0 – 1.5 %)

Table 3 summarises the experimental plan and its raw results.

4.3 Dustiness model for tile adhesives

This Central Composite Design model is based on a Fractional Factorial (that allows the quantity of experiments to be halved without loss of information for 5 or more variables). It was created to investigate dust generation in cementitious tile adhesives and includes the following components:

1) Ordinary Portland cement (20 % – 40 %)

2) Fine calcium carbonate (0 % – 20 %)

3) Coarse calcium carbonate (0 % – 20 %)

4) Redispersible polymeric powder (0 % – 10 %)

5 Cellulose fibres (0 – 2 %)

Table 4 presents the experimental plan and its raw results.

5 Experimental results

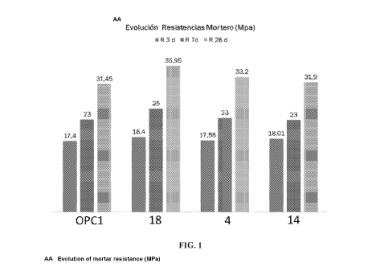

5.1 Correlations in C1 tile adhesives testing

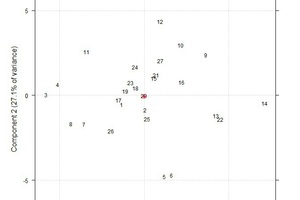

By using the Principal Component Analysis technique on the results of the “C1 adhesives” model it is possible to evaluate the correlations along the whole performance profile of cementitious tile adhesives, giving the loadings and score graphs reported in Figure 1.

Interpretation of the PCA plots provides interesting results, very similar to those found in the previous work [2]:

1) The 24 hours pull-off, initial adhesion, water immersion, freeze-thaw cycles and pull-off after heating for 5 minutes (upper right group of the loadings plot) are strongly correlated. They all are related to the amount of cement in the formulation and to the specific gravity of the adhesive

2) The open time at 20 minutes, open time at 30 minutes, adjustability and slippage are all shown in the right-hand bottom group orthogonal to the first group. These results are strongly correlated and relate to the cellulose ether content

3) These two orthogonal groups highlight the independence between the properties generated by the hydraulic binder and those related to the amount of cellulose ether present in the formulation

4) The modified cellulose ether only improves the slip test (which, naturally, has better results when the results are low) and strongly penalizes all the other results. This is because the tests performed with highly modified cellulose ether are actually located in the right-hand part of the score plot, in opposition to high pull-off values

5) The pull-off resistance after heating again shows a behaviour pattern that becomes more and more dependent on the cellulose ether when the setting time of tiles is increased. At 5 minutes it is close to the cement area of the graph, at 10 minutes it moves to an intermediate area and at 15 minutes it falls closer to cellulose ether area

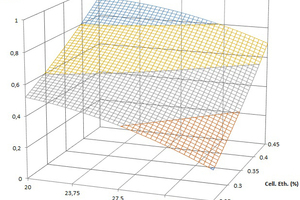

5.2 Usefulness of a set accelerator

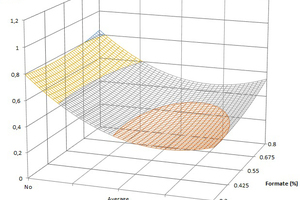

Modelling the C1 tile adhesive formulations made it possible to understand the contribution of set accelerators to the final performance of products.

Figure 3 and Figure 4 show that the sharp decrease in performance caused by the use of highly modified cellulose ethers (due to its strong retarding effect on cement hydration) can be offset, at least partially, by the use of a set accelerator. In particular, this shows its effectiveness in the pull-off results after heating. In any case, the addition of calcium formate generates a global improvement in performance. This is clearly visible in all the pull-off adhesions when using modified cellulose ether.

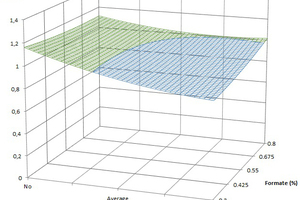

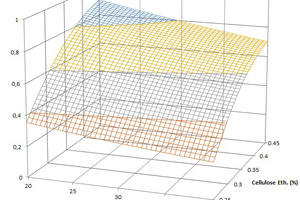

5.3 Comparison of the “C1” and “C2” models

This experimental campaign made it possible to verify the reproducibility of these Experimental Design modelling techniques, in which this “C1 model” is a sub-assembly of the “C2 model” developed in the previous work [2]. In spite of the differences in the ranges of each variable investigated (which tend to be larger in the “C2” model), the reproducibility between the two models was found to be highly impressive, as shown by Figure 4

(pull-off after water immersion), Figure 5 (open time at 20 minutes) and Figure 6 (slip resistance). Once again this highlights the excellent quality of this form of modelling.

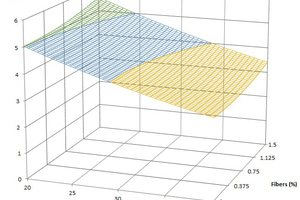

5.4 Deformability of tile adhesives

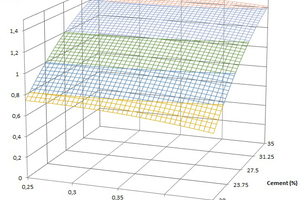

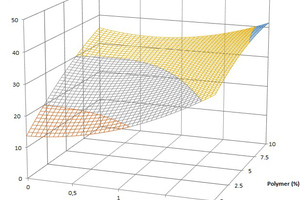

The deformability test, as verified in the dedicated deformability model, can be affected by many factors (as illustrated by Figure 7):

1) The cement tends to reduce the deformability of samples, generating a more rigid structure (with a consequent increase in breaking load and elastic modulus)

2) Together with an overall improvement in the performance of the adhesive the polymer guarantees a sharp increase in its deformability

3) Fibres can produce a slight improvement in the deformability of cementitious tile adhesives

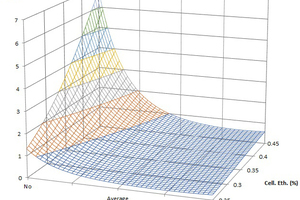

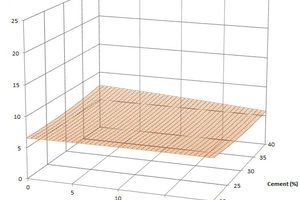

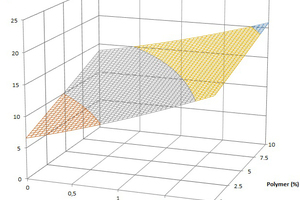

5.5 Evaluation of the dustiness of tile adhesives

The emission of dust from cementitious tile adhesives can be described by two different phenomena: the initial release of dust immediately following the act of pouring the powder into a bucket and the dust remaining at the end of the precipitation process.

These two mechanisms are described by the dustiness model generated in the present work.

The first mechanism seems to involve all the raw materials investigated: cement, calcium carbonates (fine and coarse), polymers and fibres all contribute to the generation of powder, as shown in Figure 8.

The second mechanism mainly involves the light components in the formulation, such as fibres and polymer. After 30 seconds from pouring the powder these are still floating, generating the permanent cloud of dust as shown in Figure 9.

6 Conclusions

Modelling the behaviour of different aspects of the formulation of cementitious tile adhesives using Experimental Design techniques has made significant contributions towards improving the product development. The reproducibility between independent models has also been satisfactorily demonstrated, confirming the robustness of these modelling techniques.

Very interesting results were obtained by modelling the dust formation phenomena in cementitious tile adhesives when the product is poured into a bucket for subsequent mixing with water. Two distinct mechanisms of dust formation have been highlighted - an initial cloud of dust resulting from all the formula components and a residual dustiness (that is more difficult to reduce) due to floating light particles (polymer, fibres).

Further studies of the modelling of cementitious tile adhesives will focus on the dependence of their performance on the quality of the Portland cement used in their formulations and the correlation between the composition of modified cellulose ethers and the rheological and mechanical behaviour of the finished product.

//www.mapei.com" target="_blank" >www.mapei.com:www.mapei.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.