Interactions between cellulose ethers and cements with several main constituents in a model mix formulation for tile adhesives

The interactions between (un)modified methyl hydroxyethyl celluloses and cements with several main constituents were determined using a model mix formulation for tile adhesives. The results show that these clinker-efficient cements with reduced specific CO2 emissions can also be used in complex mortar formulations and in this way increase the sustainability.

1 Introduction

Cements with further main constituents in addition to clinker have already been in use for a long time for concretes and also for plastering and masonry mortars because of their ecological, economic and technical advantages. However, formulations such as tile adhesives, which dominate in the field of premixed dry mortar, still primarily contain Portland cement. This is due to the lack of knowledge concerning the interactions between further cement main constituents additional to clinker and the admixtures that are required for such formulations. These admixtures are mainly water...

1 Introduction

Cements with further main constituents in addition to clinker have already been in use for a long time for concretes and also for plastering and masonry mortars because of their ecological, economic and technical advantages. However, formulations such as tile adhesives, which dominate in the field of premixed dry mortar, still primarily contain Portland cement. This is due to the lack of knowledge concerning the interactions between further cement main constituents additional to clinker and the admixtures that are required for such formulations. These admixtures are mainly water retention agents that enable the formulation to have the requisite water retention and a workable consistency. As water retention agent cellulose ethers such as, for example, methyl hydroxyethyl celluloses (MHEC) are normally used.

The influence of cellulose ethers and Portland cement on the water retention and workability as well as on the hydration and development of the microstructure of mortars has been the subject of a great many investigations [1]. However, there have so far been hardly any investigations into the interactions between cements with several main constituents and cellulose ethers or into the influences of modified cellulose ethers on these interactions. Modified cellulose ethers are becoming increasingly important as they increase the stability and slippage resistance to a significant extent. High slippage resistance is now a central requirement for adhesives as increasing use is being made of heavy, large-format tiles and panels.

This article discusses the influence of unmodified and modified MHECs and of cements with several main constituents on the consistency, water retention and early development of the microstructure as well as on the porosity, pore volume distribution and compressive strength of a model mix formulation of a Class 1 tile adhesive complying with EN 12004. The results of investigations into technical applications have been published in [2].

2 Materials and methods of investigation

2.1 Cellulose ethers

Two commercially available unmodified MHECs were used for reference. These are designated MC1 and MC2 below. The molecular masses and viscosities of their 2 % solutions were comparable (Table 1). The main difference lies in their proportions of methyl and hydroxyethyl groups (degrees of substitution DS and MS). The MHEC designated MC1 was modified. The modification was carried out on the one hand with 20 mass % of a commercially available starch ether (“SE”) and on the other hand with 5 mass % of a commercially available, high-molecular, weakly anionic, copolymer of acrylamide and sodium acrylate (“P”). The modified cellulose ethers are accordingly designated MC1-020SE and MC1-005P.

2.2 Portland cement

A CEM I 52,5 R Portland cement complying with EN 197-1 was used. The Portland cement, designated “Z” below, was used for reference and as the basis for producing the cements with several main constituents.

2.3 Cements with several main constituents

The cements with several main constituents were produced by mixing the Portland cement with granulated blast furnace slag or siliceous fly ash. The materials and cements fulfilled the requirements of EN 197-1. All the results are shown in the final report of the research project [3]. The designations, compositions and characteristic mechanical and physical values of the cements used in this article are given in Table 2.

2.4 Premixed dry mortar

The premixed dry mortar consisted of 30 mass % cement and 70 mass % quartz sand with a particle size range of 0.08 to 0.5 mm. 0.35 mass % cellulose ether was added to the solids unless specified otherwise. The dispersive powders and additives that are normally employed to improve the workability, setting acceleration and early strength developments were not used to permit better determination of any possible interactions of the cellulose ethers with the cement.

2.5 Mortars for tiles and panels

The premixed dry mortar was mixed with 23 mass % deionized water. The water was placed in a mixer conforming to EN 196-1 and the premixed dry mortar was added and mixed for 30 s at 140 rpm. The mixing process was then stopped for 30 s and any material adhering to the walls and base of the mixer bowl and to the stirrer was detached. The mixing process was then continued for 90 s at 140 rpm. The total mixing time was 120 s. The maturing time was 5 min.

2.6 Consistency

The consistency was determined in accordance with EN 1015-3.

2.7 Water retention

The water retention was determined in accordance with DIN 18555-7 after a suction time of 5 min. FP 2727 chromatography paper (700 g/m2) was used.

2.8 Early development of the microstructure

The development of the microstructure over the first 24 hours of hydration was determined non-destructively and continuously by ultrasound transmission. The time required to reach a defined ultrasound velocity (in this case 1000 m/s) was used to assess the early development of the microstructure.

2.9 Porosity and pore volume distribution

The open porosity and the distribution of the pores from about 4 nm to about 220 µm were determined by high-pressure mercury porosimetry in accordance with DIN 66133 on mortar samples that had hydrated for 56 days. The samples were taken from mortar prisms before the compressive strength.

2.10 Compressive strength

The compressive strengths of samples that had been stored for 56 days were determined in accordance with EN 1015-11. The test pieces were produced and stored in accordance with this standard.

3 Results

3.1 Water retention and consistency

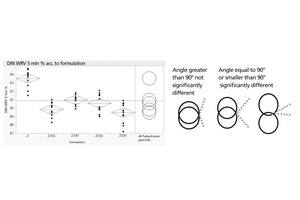

With the quantity of cellulose ether of 0.35 mass % that is normal for tile adhesives the water retention was always 100 % regardless of the combination of cement and cellulose ether. The quantity of cellulose ether was therefore reduced to 0.10 % to achieve differentiation. The results are shown in Figure 1. The left-hand ordinate shows the water retention (bar chart) and the right-hand ordinate shows the consistency (line diagram) in relation to the cement and the cellulose ether. Figure 2 contains a statistical evaluation of the results of the water retention.

The consistency of the mortars containing the modified cellulose ether MC1-005P was, as result of the high-molecular polyacrylamide, always somewhat stiffer than the other mortars, which did not differ substantially with respect to consistency (Figure 1, line diagram). Regardless of the cellulose ether used, the consistency of the samples made with Portland cement was slightly stiffer than that of the mortars made with the composite cements.

From Figure 1 (bar chart) it can also be seen that the mortars made with Portland cement have slightly higher water retention capacity than the other mortars. Between themselves these exhibited comparable levels of water retention, i.e. neither the type nor the proportion of the composite materials used had a measureable effect on the water retention capacity. This is also clear from the Tukey-Kramer statistical evaluation of the results (Figure 2).

3.2 Early development of the microstructure

The development of the ultrasound velocity as a means of assessing the development of microstructure during early hydration is shown in Figure 3 for examples of selected combinations of cellulose ether and cement. The results are shown for the mortars containing Portland cement without cellulose ether (Z) and with the modified cellulose ether MC1-005P (Z_MC1-005P) and for the mortars with this cellulose ether and with 35 or 55 mass % granulated blast furnace slag in the cement (Z35S_MC1-005P and Z55S_MC1-005P, respectively).

The cellulose ether caused a significant delay in the development of the ultrasound velocity in the mortar made with Portland cement (Figure 3,

compare Z with Z_MC1-005P). The time until the ultrasound velocity of 1000 m/s was reached was extended from about 2.2 h without cellulose ether (Z) to about 7.7 h with cellulose ether (Z_MC1-005P). The development of the ultrasound was only slightly retarded when the Portland cement was replaced by the cements containing granulated blast furnace slag while keeping the quantity of cellulose ether constant. The time until the 1000 m/s mark was reached was extended from about 7.7 h (Z_MC1-005P) by only about 1 h to about 8.8 h (Z35S_MC1-005) or by about 3 h to about 10.7 h (Z55S_MC1-005P), respectively.

The compressive strengths of the mortars made with cellulose ether and blast furnace cement Z55S were determined at the time when the 1000 m/s mark was reached (TIRAtest 28 600, force measuring range 2 kN, load increase 100 N/s). Regardless of the cellulose ether used, the compressive strength lay in the range from 0.28 MPa to 0.31 MPa with a standard deviation of 4 % to 6 %. This means that the development of the microstructure of the model mix formulation investigated can also be assessed by the ultrasound method.

Figure 4 shows the times needed to reach the 1000 m/s mark for all the combinations of cellulose ether and cement.

Regardless of the cement used, the time taken to reach the 1000 m/s mark was always longer when using the lower-substituted methyl hydroxyethyl cellulose MC2 (DSmethyl: 1.55) than when using the higher-substituted MC1 (DSmethyl: 1.76). The associated stronger retarding action of the MC2 is attributed to the influence of the lower degree of substitution by methyl groups on the hydration kinetics that is known from the literature [1, 4]. The stronger retarding action of cellulose ethers with a low degree of substitution is therefore not restricted to formulations with Portland cement but also applies to those with composite cements. Figure 4 also shows that, especially in combinations with composite cements, the modification of MC1 with starch ether (MC1-020SE) led to significant retardation, unlike that modified with polyacrylamide (MC1-005P).

Depending on the cellulose ether, the time taken to reach the 1000 m/s mark increased with decreasing proportion of clinker in the cement (Figure 4). However, this increased to a significantly smaller extent than the increase in the proportion of granulated blast furnace slag or fly ash in the cement (compare, for example, Z and MC1-005P with Z55S and MC1-005P). This means that there is no fear of any further significant retardation for formulations made with composite cements.

3.3 Pore volume distribution, porosity and compressive strength

The pore volume distribution in mortars made with Portland cement and with cement containing 55 mass % granulated blast furnace slag or fly ash with or without the unmodified cellulose ether MC1 is shown in Figure 5 and Figure 6. The cellulose ether led to the formation of pores larger than 1 µm with maxima in the range from about 1 µm to about 5 µm.

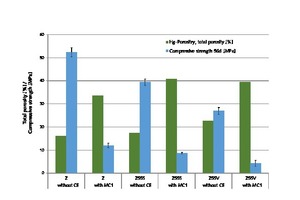

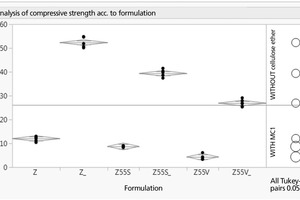

Figure 7 shows the porosity and compressive strength of the mortars without cellulose ether (without CE) and with the unmodified cellulose ether MC1. The replacement of the Portland cement (Z) by cement containing 55 mass % granulated blastfurnace slag (Z55S) or 55 mass % fly ash (Z55V) in the formulations without cellulose ether led, with the chosen type of storage, to significant drops in compressive strength from 52 to 39 or 27 MPa, respectively (Figure 7 and Figure 8). The reformulations with MC1 each exhibited significantly reduced compressive strengths to comparable level (12 and 9 or 4 MPa respectively). This is due to the air-stabilizing action of the MC1, which raised the porosity of the mortars from 16 and 17 or 23 vol. % respectively (without cellulose ether) to 34 and 41 or 39 vol. % respectively (with MC1).

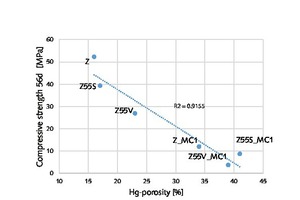

Figure 9 shows the dependence of the compressive strength on the porosity of the particular mortar. An increase in porosity is accompanied by a reduction in compressive strength. The behaviour pattern is almost linear and is independent of the formulation.

4 Conclusions

The results show that, in principle, resource-conserving, clinker-efficient cements with a clinker content that is significantly reduced by further main constituents, and therefore with substantially specific CO2 emissions, can also be used in complex formulations, such as tile adhesives, and thereby increase the sustainability still further.

The changes in the water demand, consistency, water retention and development of the microstructure as well as in the pore distribution that have been described must be taken into account during the reformulation of the premixed dry mortars so that the user still gets the expected high-quality product properties.

Funding note

The IGF project 17929 BG of the VDZ gGmbH was funded by the Federal Ministry for Economic Affairs and Energy on the basis of a decision by the German Bundestag.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.