Burner supplier backs innovative measuring technology

An example from the cement industry is examined to illustrate the combination of a burner with Endress+Hauser’s Promass I mass flowmeter, which applies the Coriolis principle. This permits not only acquisition of the classical Coriolis variables, such as mass flow, fluid density and temperature, but also quantification of the conveyed fluid’s viscosity.

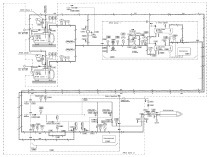

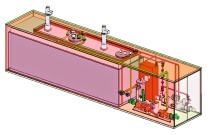

Glycerine byproduct from bio-diesel plants is used in a cement plant in Austria as a substitute fuel. This glycerine contains residual amounts of methanol, due to the production process. The fuel is stored in two horizontal tanks, which are equipped with hot-water heating. The pump installed adjacent to these tanks delivers the glycerine, heated to 30 to 50° C, firstly to a preheater and then to the burner of the calciner in the preheater tower. The more than 160 m long delivery line is fitted with trace heating. This combustion system was supplied by Unitherm Cemcon, of Vienna.

Measurement of...

Glycerine byproduct from bio-diesel plants is used in a cement plant in Austria as a substitute fuel. This glycerine contains residual amounts of methanol, due to the production process. The fuel is stored in two horizontal tanks, which are equipped with hot-water heating. The pump installed adjacent to these tanks delivers the glycerine, heated to 30 to 50° C, firstly to a preheater and then to the burner of the calciner in the preheater tower. The more than 160 m long delivery line is fitted with trace heating. This combustion system was supplied by Unitherm Cemcon, of Vienna.

Measurement of viscosity

An Endress+Hauser Promass I mass flowmeter applying the Coriolis principle is installed upstream of the calciner burner. This permits not only acquisition of the classical Coriolis variables, such as mass flow, fluid density and temperature, but also measurement of the viscosity of the conveyed fluid. The mass-flow signal is used in the burner’s control system to regulate energy input via the distribution of the fuel flows. The additional information on the glycerine’s instantaneous viscosity is used to control the preheating process. The fuel is now only heated sufficiently to assure pumpability and the correct degree of atomisation at the burner. It is thus no longer necessary to make allowance for the worst case scenario, and only the preheat temperature currently needed must be set, achieving cost savings on heating for the operator. An unregulated flow of compressed air at an excessively high fuel viscosity results in an excessively long flame in the calciner, significantly reducing the service-life of the lining, and causing downstream costs. There is, in addition, the danger of flame carry-over, with the consequence of hot streaking in the heat exchanger. Emissions rise, due to the higher CO2 contents in the flow of waste gas. Excessively high fuel viscosity results in poor atomisation, i.e., excessively large droplets, which double combustion time, impairing the combustion process in the calciner correspondingly. Viscosity measurement at the burner using the Proline Promass I eliminates these problems. The flow of compressed air for atomisation is regulated to match instantaneous conditions.

Automatic detection

In this application, measurement is also integrated into the plant’s safety concept. The relevant authorties imposed the requirement that generation of steam bubbles in glycerine preheating should be avoided and/or the hazard potential be detected in good time in its inception. The Promass I mass flowmeter detects instantaneous flow upstream of the burner. Steam bubbles in the line are indicated if this reading diverges by more than 5 % from the calculated flow for a defined period, or if the readings begin to fluctuate excessively. The Promass detects these fluctuations and its signal is used to set the system automatically to safe condition. Damage to the fuel preparation system is thus avoided.

Cost savings

The concept of a burner fitted with the Promass I mass flowmeter, as described above, is an example from the cement industry. This measuring system also generates benefits in other thermal processes, such as heating of tanks in the glass industry and of drying kilns heated using high-viscosity fuels (heavy fuel oil). Optimum atomisation controlled on the basis of instantaneous viscosity achieves better adherence to emissions limits and saves heating costs.

//www.de.endress.com/de" target="_blank" >www.de.endress.com/de:www.de.endress.com/de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.