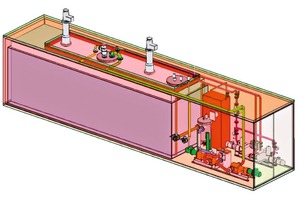

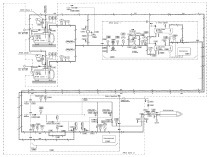

The alternative fuel container system is a flexible system to use liquid alternative fuels easily for new or existing burner systems introduced by GRECO. The fuels can be waste oil, solvents, in fact all liquid residues with a sufficient heating value, even containing water or smaller impurities. The standard 40ft LAF container is designed for filtration, storage and homogenization as well as for dosing the fuel to the burner lance. This TÜV approved system is designed and built in compliance with the ATEX guideline 94/9/EG. The storage tank, with a capacity of 37 m³, is designed as a double...

The alternative fuel container system is a flexible system to use liquid alternative fuels easily for new or existing burner systems introduced by GRECO. The fuels can be waste oil, solvents, in fact all liquid residues with a sufficient heating value, even containing water or smaller impurities. The standard 40ft LAF container is designed for filtration, storage and homogenization as well as for dosing the fuel to the burner lance. This TÜV approved system is designed and built in compliance with the ATEX guideline 94/9/EG. The storage tank, with a capacity of 37 m³, is designed as a double shell. The tank is equipped with a hot water heater connection at the tank bottom to preheat the fuel if necessary. The fuels can be mixed by 2 agitators controlled by a frequency converter. All parts of the storage tank touched by the medium are equipped with fire protection guards. The integrated unloading pump can discharge the contents of the truck into the storage tank. From there a dosing pump supplies to the burner valve train with a typical flow of 800-3500 l/h to the GRECO burner atomizing lance. The electrical cabinet with controller (Siemens Simatic S7) to regulate the system is located in the electrical niche of the container and will be delivered with a profibus interface to an external PLC.

Überschrift Bezahlschranke (EN)

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

Bestellbutton in Angebotsbox (EN)

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

Bestellbutton in Angebotsbox (EN)