Understanding the process conditions in a parallel flow regenerative kiln

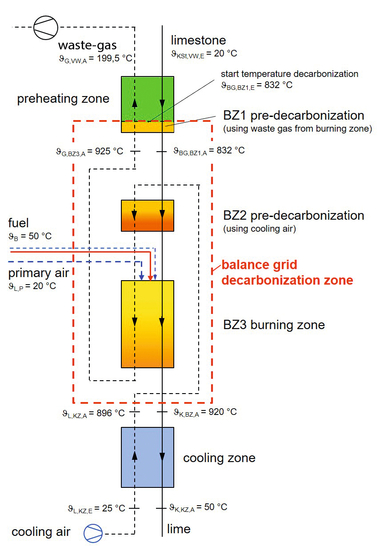

A lime manufacturer operates a 300 tons per day Parallel Flow Regenerative Kiln (PFRK), fired with natural gas. The kiln is fed with 40-80 mm limestone, but in order to maximize the use of the quarry reserve, the company wished to explore the possibility to feed the kiln with smaller and coarser particle size distribution. Besides, depending on the weather conditions, the moisture content of the stone widely varies and impacts the heat consumption of the kiln. The scope of the study was then to quantify the influence of the stone size and its moisture content on the kiln process. To lead this study, EESAC has developed a mathematical model able to: determine the heat and mass balance of the kiln, calculate the stone and gas temperatures in a selected part of the kiln and assess the pressure drop along the shafts.

1 Initial status

The first step of the study consisted in establishing a global heat and mass balance of the kiln. The energy balance is summarized in Table 1.

The energy balance actually highlighted the fact that more than 8 % of the total heat input (natural gas) was used to dry the limestone in the preheating zone of the kiln. At the time of the study the kiln feed moisture was 6.9 %.

Then, in order to better understand the kiln burning conditions, the temperature profile of the kiln was measured. The measurement was carried out with a 25 meter long thermocouple inserted at the top of the...

1 Initial status

The first step of the study consisted in establishing a global heat and mass balance of the kiln. The energy balance is summarized in Table 1.

The energy balance actually highlighted the fact that more than 8 % of the total heat input (natural gas) was used to dry the limestone in the preheating zone of the kiln. At the time of the study the kiln feed moisture was 6.9 %.

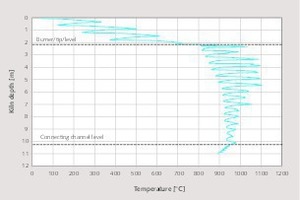

Then, in order to better understand the kiln burning conditions, the temperature profile of the kiln was measured. The measurement was carried out with a 25 meter long thermocouple inserted at the top of the stone bed. The thermocouple was then caught by the stones, and therefore travelled along the kiln. The temperatures were recorded via a data logger. Four thermocouples were used for this measurement (two thermocouples per shaft). The velocity of the stone bed was measured. It was then possible to draw an average temperature profile of the kiln bed, as displayed in Figure 1.

Figure 1 then provides fundamental information which could be used to calculate, with a heat transfer model, the stone and gas temperature profiles in the kiln:

The size of the lances was ± 1.9 m long, whereas the lime manufacturer indicated 3.6 m. The preheating zone was therefore shorter than expected.

The stone bed temperature at the burner tip level was ± 700 °C. Typical measured values on other PFR kilns are rather around 815 °C. This is actually a consequence of the short preheating zone described above.

The lime temperature at the connecting channel level was ± 980 °C.

The final information required for the model was the kiln feed characteristics. The kiln model actually uses a packed bed of sphere, with a diameter corresponding to the equivalent sphere diameter of the kiln feed. The particle size distribution of the limestone was determined, and the Sauter diameter [2] was then calculated. The equivalent sphere diameter of the kiln feed was then calculated by correcting the Sauter diameter with a shape factor. Besides, the stone bed porosity was assessed based on EESAC experience.

2 Baseline case results

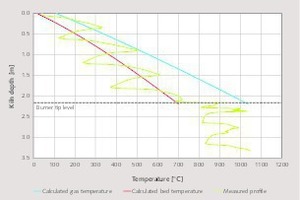

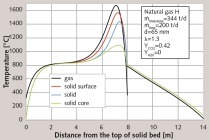

The model used for calculating the temperature profiles of the gas and the stone bed in the preheating zone. The calculation was made to heat up the stone bed from 17 °C (kiln feed temperature) to 700 °C (stone bed temperature at the burner tip level). Figure 2 displays the calculated temperatures profiles together with the measured profile.

A good correlation could be observed between the measurement and the calculated stone temperature profile in the preheating zone. The calculated gas temperatures in this zone were ranging between 110 °C (at kiln exit) and 1036 °C at the burner tip level. Based on EESAC experience, the gas temperature calculated here is close to the temperature at the end of the preheating cycle. The calculated value is then close to the measured gas values, where the maximum gas temperature is typically 117 °C.

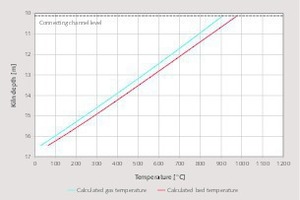

As for the preheating zone, the temperature profiles of the cooling zone were calculated (see Figure 3). The calculation was made to cool down the stone bed from 980 °C (stone bed temperature at the connecting channel level) to 55 °C (average lime temperature at cooler exit indicated).

In the cooling zone, the air temperatures range from 30 °C (at kiln discharge level) to 910 °C (at connecting channel level).

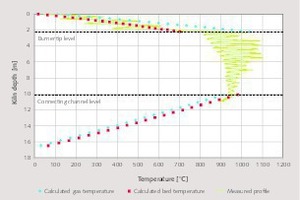

Finally, the calculated and measured temperature profiles were all displayed in Figure 4.

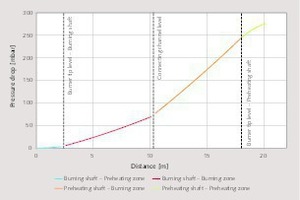

The pressure drop was calculated. Figure 5 indicates the pressure drop through the kiln from the burning shaft to the preheating shaft.

The overall calculated pressure drop is in line with pressure measurements on the kiln. For example, the pressure of the combustion air was 280 mbar when the overall calculated pressure drop of the kiln was 277 mbar.

3 Influence of the stone moisture content

Based on the information provided by the lime manufacturer, the moisture content of the kiln feed could vary from 5 to 12 %. The kiln model was then used to study the influence of the stone moisture content on the kiln parameters.

As displayed in Table 2, the increase of the stone moisture leads to a significant increase of the heat consumption of the kiln. When the moisture reaches 12 %, the stone drying represents 14 % of the total heat provided to the kiln.

4 Influence of the stone diameter

Three stone sizes were tested in the model:

Smaller stones than in the baseline case: sphere diameter equal to 0.75 times the sphere diameter.

Larger stones than in the baseline case: sphere diameters equal to 1.25 and 1.5 times the sphere diameter of the base case.

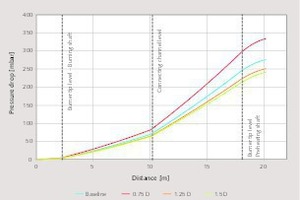

Figure 6 displays the variation of the kiln pressure drop with the different stone diameters tested in the model.

Increasing the stone size reduces the pressure drop. Actually, the surface of the larger stones is lower: less energy is therefore required by the gas phase to travel through the stone bed.

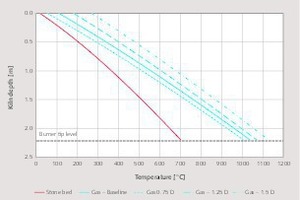

The model was then used to calculate the gas temperature profiles in the preheating zone of the kiln. The calculations were made on the basis of heating up the stone bed from 17 °C (kiln feed temperature) to 700 °C (stone bed temperature at the burner tip level) on a layer of 2.2 meters (length of the preheating zone). Figure 7 displays the temperature profiles of the stone bed and the gas with the various stone sizes tested.

As explained earlier, the increase of the stone size reduces the stone surface in contact with the gas. This is why the heat exchange is less efficient when the stone size increases and therefore why the kiln flue gas temperature is higher (poorer heat recovery capacity of the kiln). At the same time, higher energy is necessary to ensure the heat exchange along the preheating zone. This is why the gas temperature at the burner tip level increases with the stone size.

Besides, the increase of the kiln flue gas temperature (which is actually a loss of energy) with coarser stones contributes to an increase of the heat consumption of the kiln, as indicated in Table 3.

It is also important to take into account that the use of smaller stones may contribute to water condensation in the kiln flue gas due to the lower temperature reached at the kiln exit. Such a phenomenon may cause corrosion issues, as well as bag house filter damage.

In order to avoid high energy consumption (with coarser stones) or to prevent water condensation in the kiln flue gas, one possibility would consist in adjusting the length of the preheating zone. Table 4 indicates the variation of the preheating zone size necessary to maintain the kiln flue gas temperature at 110 °C (baseline situation) for each stone size tested.

Adjusting the height of the preheating zone can either be achieved by playing on the size of the lances or by playing on the stone level above the lances.

5 Perspectives

The lime manufacturer is now able to anticipate the influence of the kiln feed properties (stone size and moisture) on the kiln process. Actually, the moisture content of the stone widely influences the overall heat consumption of the kiln. However, the kiln flue gas temperature is the major contributor to the heat losses in PFRK’s. This has been clearly demonstrated when various stone sizes were tested in the model. The stone size makes a major contribution to the heat recovery capacity of PFRK’s. Thus an adjustment of the height of the preheating zone as a function of the stone size would contribute to maintain the constant heat recovery of the kiln, and therefore would maintain constant heat consumption.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.