An initiative for alternative fuels

co-processing in the cement kiln

At Dalla Cement Factory a conscientious initiative to search for opportunities to utilize hazardous and non-hazardous industrial/domestic waste from nearby areas as alternative fuels has been taken. The company has been making concerted efforts to increase the Thermal Substitution Rate (TSR) up to 5 % by 2016 and target to achieve 20 % up to 2020.

1 Introduction

The energy crises and fast depleting natural resources have become a matter of great concern and have created awareness all over the world. The global impact of the cement industry is to use alternative fuels for the substitution of fossil fuel, the reduction of CO2 emissions, to improve the sustainability of the environment and to preserve natural resources.

In pursuit of the above objectives a conscientious initiative has been taken at Dalla Cement Factory (DCF) to explore the availability of multiple alternative fuels, hazardous and non-hazardous industrial waste, bio mass etc....

1 Introduction

The energy crises and fast depleting natural resources have become a matter of great concern and have created awareness all over the world. The global impact of the cement industry is to use alternative fuels for the substitution of fossil fuel, the reduction of CO2 emissions, to improve the sustainability of the environment and to preserve natural resources.

In pursuit of the above objectives a conscientious initiative has been taken at Dalla Cement Factory (DCF) to explore the availability of multiple alternative fuels, hazardous and non-hazardous industrial waste, bio mass etc. in the vicinity area for co-processing in the cement kilns.

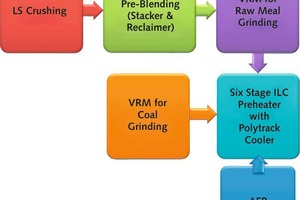

Dalla Cement Factory is a cement clinkerization unit in the Eastern & Central Uttar Pradesh (Figure 1). It is a responsibility to conserve the precious natural resources and, most importantly, to preserve environmentally the fossil fuel (coal).

As a responsible stake holder in Uttar Pradesh (U.P.) a conscientious initiative has been taken at the Dalla Cement Factory to search for opportunities to utilize hazardous and non-hazardous industrial/domestic waste from nearby areas as alternative fuels.

The Thermal Substitution Rate (TSR) of fossil fuel by alternative fuels ranges between 0.5 to 1 % in India, much below the 30 to 80 % achieved in European countries.

The Dalla Cement Factory has been making concerted efforts to increase the thermal substitution rate (TSR) to 5 % by 2016 and target to achieve 20 % up to 2020.

2 Initiative for alternative fuels

It has been emphasized to undertake continuous exploration of the possibilities to identify various types of industrial, urban, rural and colony solid waste which should be reduced, recycled and reused as an alternative fuel converting waste into energy as it offers immense opportunities for converting trash into cash and economy in operation.

In line with this, a committee has been constituted in October 2014 at plant level to undertake this exercise as a mission i.e. a new initiative for attaining operational efficiency and economy in the plant operation at the “Dalla Cement Factory” with the available facilities and infrastructure at site (Figure 2).

Steeply rising energy costs and stringent environment standards have forced cement manufacturers worldwide to evaluate the substitution of conventional fossil fuels by various types of alternative fuels.

Various alternative fuels like bio-mass, municipal solid waste, agricultural waste, used tyres, effluent treatment plants (ETP) and sewage treatment plant (STP) sludge and many more hazardous and non-hazardous industrial wastes generated in India, possess a large amount of energy that could be used for co-processing in the rotary cement kiln for replacement of the fossil fuel (coal).

To keep pace with the fast technological developments taking place for co-processing AFR in the rotary cement kiln to achieve a higher TSR to reduce fossil fuel, it has become imperative that a process of regular thinking, deliberations and evaluations of various options of AFR availability has to be done by a team of knowledgeable personnel.

3 Alternative fuels

The following domestic and industrial waste have been identified and analyzed in the laboratory for further use to substitute coal in the plants (Table 1).

3.1 Non-hazardous waste

Some of the non-hazardous waste materials have high calorific values, while the rest has marginal calorific values. Various type of AFR are available abundantly, while a few are seasonal and in much less quantity.

Biodiesel is an eco-friendly alternative liquid fuel prepared from domestic renewable resources i.e. vegetables oils.

After receipt of these materials at site, pilot co-processing trial runs in the rotary cement kiln and preheater were successfully undertaken at site in the presence of representatives from M/s Vimita Lab, Hyderabad, and plant personnel.

3.2 AFR (RDF) processing and storage

After identification of several waste materials, a confined area for AFR storage and processing facility was established with marginal investment outside the plant premises. Initially a local cattle feed cutting machine was identified and installed to make a small shredder for processing AFR modified from manual to motorized operation.

After a successful trial run and optimization of the process, another shredder machine was designed and manufactured in the plant’s workshop for processing AFR of 20-50 mm size (Figures 3–5).

3.3 AFR (RDF) lifting and feeding system

in the kiln-preheater on the third floor

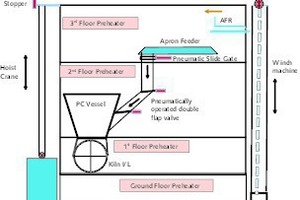

For co-processing AFR in kiln-precalcinator, a winch and hoist system was incorporated to lift the processed material to the preheater on the third floor.

An AFR feeding system was installed for controlled flow with absolute weighing features consisting of an apron feeder with a variable-frequency drive (VFD), a feed hopper, a slide gate and two pneumatically operated double flap valves to arrest false air ingress in the kiln system as indicated in Figure 6.

3.4 Tyre chips loading and unloading system

Tyre chips are now commonly used as alternative fuel in the cement industry due to its high calorific value and easy processing. A separate loading system for filling in a bulker and a pneumatic unloading system was installed at the raw coal hopper.

To increase the consumption of tyre chips, controlled proportionate mixing in the coal stacker/reclaimer has also been initiated (Figure 7).

3.5 Rice husk feeding

Being in an agricultural area, large amounts of biomass are available for co-processing. Rice husk is being mixed with coal in a proportionate quantity in the coal stacker/reclaimer for regular consumption with coal. A feeding system for rice husk was installed directly through the kiln firing main burner.

3.6 Hazardous waste

After the successful use of non-hazardous waste, some of the hazardous wastes were identified also for procurement and co-processing in the cement kiln as mentioned below in Table 2.

Application of thermal processing of hazardous waste is constrained by the high capital investments, the need for skilled personnel and the requirements for high operating and safety standards.

A long term agreement was entered into with TATA Motors and Asian Paints for co-processing of hazardous waste in the cement kilns i.e. paint sludge etc. as an alternative fuel. Paint sludge is fed with the mixing of biomass and other solid waste in the kiln precalciner.

Permission from the Central Pollution Control Board (CPCB) was received for co-processing of pharma waste and the procurement is under progress.

4 Results and prospects

4.1 Carbon emission reduction

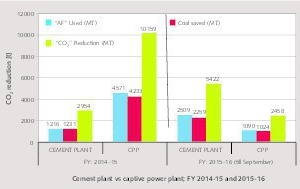

Figure 8 descibes the CO2 reduction in comparison to the alternative fuels used and the coal saved for the years 2014 and 2015.

4.2 Increasing TSR for substituting fossil fuels

and conservation of natural resources

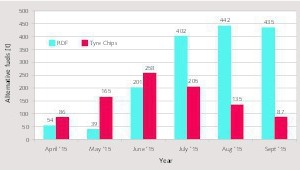

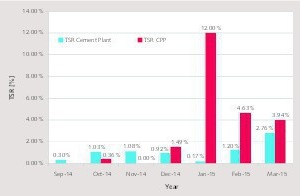

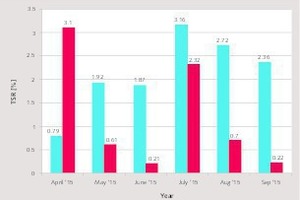

The development of the thermal substitution rate for the years 2014 and 2015 is depicted in Figures 9 and 10.

Table 3 shows the Dalla Cement Factory’s roadmap for the planned achievement in using alternative fuels for the year up to 2020.

The improvement of the AFR process and the investments necessary for this are shown in Table 4.

5 Conclusion

Alternative fuel and raw materials co-processing in the cement plant has been the most suitable and preferred technology for waste management to recover energy and materials with no adverse effect on the kiln operation, product quality and emission levels. The co-processing of alternative fuels substitution program in the cement kiln has been taken as integral part of the cement plant operation at the Dalla Cement Factory to reduce fuel costs, green house gases (GHG) and to improve the sustainability of the environment. The policies and guidelines for AFR co-processing need to be modified on the “Pollutor to pay for waste generation” principle to encourage the Indian cement industry to achieve a high thermal substitution rate (TSR) to preserve fossil fuels and for a sustainable environment.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.