Pre-processing hazardous waste

The SID Group is known as a supplier of shredding equipment and also works in the conception, design, and manufacturing of complete pretreatment and homogenization units for hazardous waste. This Shredding-Mixing-Pumping system SID successfully transposed from hazardous waste incineration into the cement industry for the preparation and injection of alternative fuel (AF).

1 Introduction

The first SMP installation for the cement industry was delivered in 2005 to the BBMG Beijing cement plant, China. Up to now SID received several additional contracts for the delivery of similar SMP plants. The latest SMP installation was put into operation in March 2014 in one of China’s biggest cement plants from Hongshi.

Since the commissioning of the first pretreatment installation at BBMG, the cement manufacturer benefits from the advantages of this proved technology for the incineration of its alternative fuel. All pretreatment and homogenization units are composed of three...

1 Introduction

The first SMP installation for the cement industry was delivered in 2005 to the BBMG Beijing cement plant, China. Up to now SID received several additional contracts for the delivery of similar SMP plants. The latest SMP installation was put into operation in March 2014 in one of China’s biggest cement plants from Hongshi.

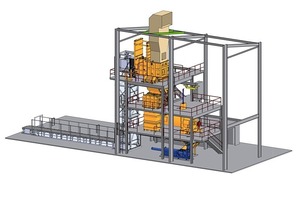

Since the commissioning of the first pretreatment installation at BBMG, the cement manufacturer benefits from the advantages of this proved technology for the incineration of its alternative fuel. All pretreatment and homogenization units are composed of three main parts entirely supplied by the SID Group: shredder, mixer and solid-pump. Their objective is the pretreatment of hazardous waste slurry which is fed directly into the cement kiln. Hazardous waste and its derived alternative fuel can have various differences in consistency. They can be solid, liquid or pasty with different densities, different viscosities, different dry material contents, and different particle sizes, etc.

After quality assessment the pretreatment and homogenization units from the SID Group enable the cement manufacturer to use many preselected and eligible types of waste in different consistencies together in one installation. In order to create a suitable menu for co-processing, i.e. calorific value, ash and heavy metal content or consistence, an appropriate and constant quality of slurry can be achieved.

The special pumping technology used in the SMP system allows the cement manufacturer to pump slurries through a high density pipe to the injection lance delivering the slurries into the precalciner as easily as liquids. The high density pipe can easily be routed to any configuration and integrated into an existing plant.

2 Co-processing in cement kilns

The outstanding performance of the cement production process, with its high temperatures of around 2000 °C and super-stoichiometric lime content and its resulting dry sorption effect, provides a certain duality of co-processing, which is explicitly mentioned in the Stockholm Convention for the elimination of hazardous waste containing persistent organic pollutants, on the one hand, and for the process support of pre-processed waste derived fuels as a working stock, on the other hand.

This knowledge has, of course, evolved into globally allocated concepts which nonetheless offer country-specific solutions for the establishment of a win-win situation for both the public and private sectors, globally. Cement kilns are in operation around the world close to industrial and population centers where daily accruing hazardous and non-hazardous waste is available. Captivated in under utilization of their capacities they compensate their costs for downtime by co-processing of waste, which would need to be disposed of in a safe and timely manner.

The expertise gained by the SID Group over the years in the technology of waste treatment by providing pretreatment, homogenization and handling units brings a lot of benefits to the cement industry.

3 The Shredding-Mixing-Pumping system

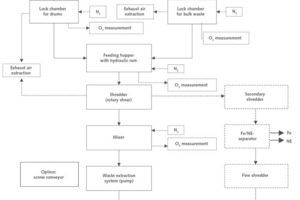

The SMP Installations provided by the SlD Group are turnkey solutions customized to specific local needs. The objective is the preparation of slurry and its injection into the precalciner. Usually these systems include SMP steps coupled with a blanketing system (injection of N2) helping to reduce the amount of oxygen present in the system, controlled by online measurements of the oxygen content in the critical parts of the system. This allows the treatment of mixtures with a certain potential for explosion.

3.1 Feeding system

The feeding system for the pretreatment and homogenization unit depends strongly on the local conditioning of the waste. The feeding of the installation can be done by a crane through a feeding hopper, via containers and a skip, via drums or pallets by conveyors or hosting devices.

The SMP system is composed of a shredding step (Fig. 1) using a rotary shear for the solid waste and industrial sludge. Rotary shears reduce the size of objects by cutting, tearing and breaking forces. SlD shears, equipped with a powerful hydraulic drive, have been developed to treat the widest range of materials such as for example bulky process rejects and industrial waste like tires, carpets, plastic, and steel bins and even white goods, which are widely known as not being part of AFR feedstock.

3.2 The mixing step

Once the containers, drums, etc. are opened and their content is shredded, the mixture of industrial sludge and solid waste enters the mixer (Fig. 2) by a hopper located below the shredder and is mixed with organic liquid waste or waste water for mass and calorific adjustment. The mixer allows the preparation of a homogenous fuel blend regarding the required parameters such as calorific value, composition, consistence etc.. Due to the storage capacity of the mixer a continuous feeding of fuel slurry to the pump is enabled. The prepared pasty slurry is then pumped by means of a piston pump through a lance into the precalciner located at the best position for combustion and retention time.

3.3 Pumping technology

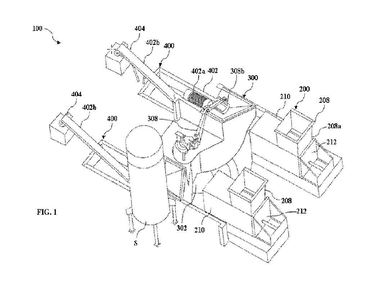

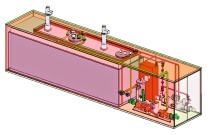

The special pumping technology used in SMP systems is provided by SID Solid Pumps. This department of the SID Group supplies piston pumps used for the transport under high pressure of sludge and slurries containing varying proportions of solid objects (Fig. 3 and 4).

The single piston pump with slide gate is designed to convey difficult products with a high percentage of dry-solids and foreign objects such as for example drums stripes, wood, or other disruptives. The high pumping pressure achieved by these pumps allows a very wide range of products to be transported, long pumping distances are possible and the pump is also less sensitive to foreign objects. A restricted tolerance in the cutting area brings an outstanding cutting effect in case of foreign objects inside the slurry.

The high density pipe which transports the alternative fuel to the precalciner can be integrated easily into an existing plant.

4 The advantages of SMP

With heavy metals contaminated hazardous waste is only for disposal outside the cement industry, whilst organically contaminated hazardous waste is ideal for co-processing. The essential difference in co-processing in the cement plant is its higher energy efficiency and recovery in direct use in the process.

According to indications transmitted by operators of the SID Group SMP-plants, the main advantages are:

a huge range of different pasty waste can be treated easily, even with closed containers without outside opening

improving the safety at work by minimizing the contacts between the operator and waste due to the automatic and confined closed system of shredding, feeding, mixing and pumping,

quality and homogeneity can easily be realized by shredding and mixing, which contributes to a stable kiln run during incineration,

increase availability of the kiln by equalizing the heat load,

reduction of the emission peaks.

5 Experiences with the BBMG Beijing SMP system

In 2005 the SID Group successfully transposed the technology from hazardous waste incineration into the cement industry for the preparation and injection of pasty alternative fuels into the cement kiln (Fig. 5). The installation was put into operation in September 2005 at the BBMG Beijing Cement Plant Co. Ltd. So far, several 100.000 t of waste passed through the installed SMP unit and were fed into the precalciner without any severe break and to the entire satisfaction of the cement manufacturer.

The industrial practices of BBMG Beijing Cement Plant Co, Ltd confirmed the advantages of the SMP system provided by the SID Group and has no negative impact on the quality of the cement production and meets the requirements of pollution control in strict conformity with the Chinese national standards.

The SID Group’s SMP-system shows in practice its sound and comfortable handling of hazardous waste and the positive influence on all following thermal processes.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.