Alternative fuels at Nesher Israel Cement Enterprises

Nesher Cement has made substantial progress with its alternative fuels program, reaching a fuel substitution level of 20 %, using several types of alternative fuels. Nesher plans on increasing the use of alternative fuels, with an interim goal of reaching 40 % by 2020, despite local constraints such as low landfilling fees and excessive bureaucracy.

1 Introduction

Nesher Israel Cement Enterprises, founded in 1923, is one of the leading cement manufacturer in Israel and one of the cornerstones of the development of the Israeli construction and infrastructure industry. The Company provides most of the cement consumed by the Israeli market, as well as to the Palestinian Authority.

Nesher operates in two main sites: a grinding plant in the city of Nesher near Haifa in northern Israel (the city of Nesher is named after the plant), and a fully integrated plant in the city of Ramla near Tel-Aviv (central Israel).

The Nesher (Haifa) plant, which...

1 Introduction

Nesher Israel Cement Enterprises, founded in 1923, is one of the leading cement manufacturer in Israel and one of the cornerstones of the development of the Israeli construction and infrastructure industry. The Company provides most of the cement consumed by the Israeli market, as well as to the Palestinian Authority.

Nesher operates in two main sites: a grinding plant in the city of Nesher near Haifa in northern Israel (the city of Nesher is named after the plant), and a fully integrated plant in the city of Ramla near Tel-Aviv (central Israel).

The Nesher (Haifa) plant, which started operations in 1925, was Nesher’s first production site, back then a fully integrated plant and the first and only cement plant in the entire Middle East. Nowadays, the site serves as a grinding plant, with three cement mills producing more than one million tons of cement per year. Most of Nesher’s cement is produced at the Ramla plant, one of the largest cement plants in the western world, producing approximately five million tons of cement per year, based on two dry kilns with a capacity of approximately 12 000 t of clinker per day, and seven cement mills.

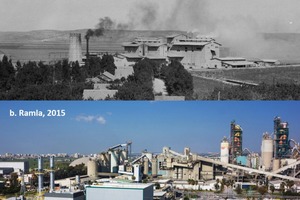

2 Sustainability at Nesher

Sustainability is one of Nesher’s core values, and as such, it directs its development activities accordingly. The company shut down its wet kilns nearly twenty years ago and now operates efficient modern dry kilns only, which were built in the 1990’s. The electrical power needs of the plants are supplied via gas turbines operated by natural gas, which were built by Nesher’s mother company. Emissions control devices (baghouses, electrostatic precipitators, and SNCR- selective non-catalytic reduction systems) were installed throughout the entire manufacturing process. A visual comparison of the historic facility in Nesher (Haifa) (Figure 1a, taken around 1930) to the current facility in Ramla (Figure 1b), shows how much the cement industry has progressed in terms of environmental performance throughout the years. While the former shows both dust emissions from the plant stacks (on the right) and black smoke from the internal power plant (on the left), the latter shows no evident dust emissions during normal operations, and electricity production (natural gas turbine, on the left) does not, obviously, generate black smoke.

The three main sustainability principles at Nesher are:

Emissions controls and targets – all emissions sources at Nesher are equipped with Best Available Technology (BAT) emissions controls, and emissions benchmarking (g/t clinker) show excellent performance based on data published by the World Business Council for Sustainable Development - Cement Sustainability Initiative (WBCSD CSI) (for further details, please see Nesher’s Corporate Social Responsibility report on Nesher’s website [1]

Sustainable resources Management – Nesher utilizes many alternative raw materials in its production process (such as coal fly ash, flue gas desulphurization gypsum, ground granulated blast furnace slag and others). On an annual basis, approximately 12 % of the raw materials used by Nesher are secondary raw materials. In addition, the use of alternative fuels has increased substantially over the last several years, as detailed in section 4

Greenhouse gas emissions reductions – achieved via a combination of energy efficiency of the dry kilns, increased use of refuse derived fuel (including biomass), and via reduction of the clinker/cement ratio (the latter unfortunately inhibited by the local policy prohibiting the import of coal fly ash, which Nesher is currently challenging)

3 Alternative fuels in the cement industry

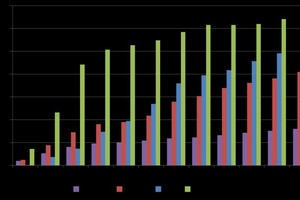

The use of alternative fuels has become common practice in the cement industry over the past two decades (Figure 2). The EU28 average fuel substitution (or co-processing) rate, as of 2014, stands at 41 % fuel substitution (up from 2 % in 1990), with Germany leading the curve, at 65 % fuel substitution in 2014 (up from 7 % in 1990). The worldwide average, as of 2014, stands at 16 % fuel substitution.

As such, the cement industry worldwide provides an end solution to both industrial and municipal wastes, while recovering their energy content and minimizing waste landfilling. In addition, the use of alternative fuels enables reduction of greenhouse gas emissions from the clinker production process due to their biomass content. This, with no increase in emissions levels from the kilns, due to the high temperatures in the kiln and the adsorption of ashes in the clinker itself. As such, the cement industry serves as a perfect example of the shift from a linear economy to circular economy, where waste and by-products are utilized in the production stage.

4 Nesher’s alternative fuels program

Nesher started using alternative fuels in the early 2000’s, when a system for storing and feeding spent solvents (e.g., from the pharmaceutical industry) was built at the Ramla plant. For nearly a decade, the fuel substitution rate (percent of alternative fuels out of the total fuels used at the facility) at Nesher remained at a low 1-2 %, with the main fuel being petroleum coke (petcoke).

In 2003 Nesher initiated an experiment for using scrap tires as an energy source at its Har-Tuv plant (which was sold in 2015 and is no longer owned by Nesher), but the experiment was never approved by the Israeli Ministry of Environmental Protection due to public concerns and pressure.

A few years later, as alternative fuels became common practice in the EU, the local regulatory atmosphere in Israel matured and allowed for initial experiments in the field. In 2009 Nesher conducted an experiment for using refuse derived fuel (RDF) at its Ramla plant. The experiment was successful and a permit for using RDF at Ramla’s kiln #2 was granted. This was however limited by a feed rate of 10 t/h and a substitution rate of no more than 40 %. The permit was expanded to kiln #1 in 2014, as part of the air emissions permit from the Ministry of Environmental Protection, but the limitations on the feeding rates remain (see Section 5).

Following the successful 2009 experiment, discussions started between Nesher and the Dan Municipal Sanitation Association (Tel-Aviv region) regarding the use of RDF to be produced from the municipal waste of the Tel-Aviv region. The background for these discussions was the planned increases in landfilling fees in Israel, from 10 New Israeli Shekels per ton (approximately 2.5 €/t) in 2007, to 100 NIS/t in 2012 (approximately 25 €/t). These increased landfilling fees, while still substantially lower than in the EU, provided the financial basis for Nesher’s RDF program.

In 2012, an agreement was signed between Nesher, the Dan Municipal Sanitation Association, and Veolia Israel (now known as Veridis), for building a RDF plant at the former Tel-Aviv region landfill (Hiriya), to be used by Nesher. Mount Hiriya is a former municipal landfill located southeast of Tel Aviv, which stands approximately 60 m high (Figure 3a). Approximately 25 million t of MSW were piled at Hiriya from 1952 until 1998, when the landfill was closed and the site converted into a MSW sorting site. Various recycling systems have been integrated at the site, such as separation of organic and non-organic waste materials, the sorting and processing of construction waste, the extraction of biogas, and of course the newly built RDF plant (Figure 3c, d; also featured in a short video [2]). Mount Hiriya itself has gone substantial transformation and rehabilitation, and now serves as a public park (Figure 3b).

Construction of the RDF plant started in late 2013, and trial runs were conducted in 2016. The plant was officially launched in March 2017, with capital expenses reaching more than 75 million Euros (funded by Nesher and its partners, with no governmental support). At full capacity, the site will sort one half of the MSW of the Tel-Aviv region (approximately 500 000 t/a), of which approximately 150 000 t of RDF will be produced per year, placing the Hiriya RDF plant as one of the largest in the world. These quantities translate roughly to a feed rate of 10 t/h for each of the two kilns at the Nesher Ramla plant, and to approximately a 20 % fuel substitution rate.

In 2013 Nesher also started using RDF from industrial sources, and as of 2017 (Jan-Aug), approximately 30 000 t of industrial RDF were used by Nesher. In addition to the use of industrial and municipal RDF as energy sources, Nesher also uses chopped scrap tires, at an annual rate of more than 25 000 t/a.

To facilitate these amounts of RDF, a state-of-the-art storage and feeding system was built at the Nesher Ramla facility. The capacity of the storage hall (Figure 4) is approximately 1200 t, providing a buffer in case of supply shortages (e.g., weekends, holidays etc.). To avoid any potential odor issues arising from the storage hall, it is kept at a low pressure, and the filtrated air is directed to the kiln (where any potential odor causing compounds are combusted). Capital expenses for building the storing and feeding system at the plant exceeded € 15 million - all of which funded by Nesher, with no governmental support. In 2015, the Israeli Ministry of Environmental Protection, along with the Manufacturer’s Association of Israel, awarded Nesher with the “Industry in the Environment Award”, for its accomplishments in the field of alternative fuels, and for providing a waste end-solution and environmental benefits at the national level.

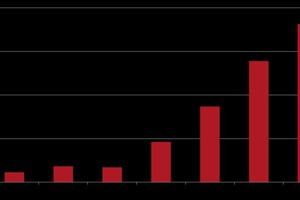

The combination of these four main types of alternative fuels (spent solvents, municipal and industrial RDF, scrap tires), and their increased use in the last several years, allowed increasing the fuel substitution rates at Nesher from a low of 1-2 % in 2011 to nearly 20 % in 2017 (Jan-Aug; Figure 5). With increased production capacity at the Hiriya RDF plant in the upcoming years, Nesher expects to double the substitution rates and reach a level of 40 % substitution by 2020.

5 Regulatory Barriers

Local waste management practices as well as environmental regulations present many barriers to the use of alternative fuels in the Israeli cement industry. The use of alternative fuels, while clearly beneficial from an environmental standpoint, has to be economically viable as well. To ensure this, waste landfilling fees need to be high enough, otherwise there is no financial incentive to divert from landfilling to more advanced waste treatment methods. As previously mentioned, landfilling fees increased substantially in Israel in the last decade, but these are still substantially lower compared to typical levels in the EU, limiting the financial incentive for using alternative fuels. While many cement plants in the EU are paid to use alternative fuels (by the waste owners) as a result of either a ban on landfilling or high landfilling fees, Nesher purchases the local RDF due to the low landfilling fees in Israel. In addition, as previously stated, Nesher and its partners in the RDF program received no governmental financial support, despite the national-level environmental benefits of this initiative.

In addition, several limitations in the air permitting process inhibit the use of alternative fuels in Israel. While cement plants in the EU are not typically limited by fuel substitution rates (or feeding rates) as long as stack emissions limit values are being met, Nesher’s air permit limits the use of alternative fuels at both a 10 t/h per kiln feeding limit and an overall 40 % energy substitution level. The 10 t/h limitation arises from the original experiment using RDF back in 2009, as 10 t/h was the maximum feeding rate tested at the time. The 40 % limitation arises from a misinterpretation of the European Industrial Emissions Directive (Directive 2010/75/EU, Article 46), according to which a ‘waste incineration plant’ classification (rather than a co-incineration plant) is triggered if more than 40 % of the resulting heat release comes from hazardous waste. The local adaptation was a total limit of 40 % fuel substitution, regardless of the fact the hazardous wastes used as alternative fuels at Nesher substitute only a few percent (1-2 %) of the total thermal energy at the kilns. Nesher is currently undergoing experiments with the Israeli Ministry of Environmental Protection to lift the 10 t/h limit (to 20 t/h), and will also need to go through an additional process of lifting the 40 % fuel substitution limit, in order to further progress with its alternative fuels program. The reason for these regulatory barriers is unclear, given how widespread the use of alternative fuels is in the European cement industry (the 40 % fuel substitution limit is even lower than current average substitution level in the EU).

Unfortunately, these bureaucratic limitations, as well as the overall waste management practices, inhibit the use of alternative fuels in the Israeli cement industry. This is also in line with findings in a recently published study by ECOFYS [3], listing poor waste management practices (e.g., high degree of landfilling and low landfilling fees) and excessive bureaucracy as factors limiting the uptake of alternative fuels. The study concludes that “local factors constrain the market potential [to use alternative fuels, AM] to a much larger extent than the technical and economic feasibility of the cement industry itself”, stating that generally “countries with lower share of landfilling have a higher co-processing rate” and that “In most countries, there are no perceived permitting issues. However, in countries with this barrier (Spain, Italy and Greece) [Israel was not included in the study, AM] the development of co-processing is severely slowed down”.

In summary, Nesher Cement has made substantial progress with its alternative fuels program, reaching a fuel substitution level of 20 %, using several types of alternative fuels. Nesher plans on increasing the use of alternative fuels, with an interim goal of reaching 40 % by 2020, despite local constraints such as low landfilling fees and excessive bureaucracy.

//www.nesher.co.il" target="_blank" >www.nesher.co.il:www.nesher.co.il

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.