Proven experience with alternative fuels in the cement kiln process

In times of increasing energy costs, it is of vital interest for any company to save energy. To cut the energy costs for clinker production, the German cement industry started substitution of primary fuels with Alternative Fuels (AF) such as used oil or tyres after the first oil crisis of 1973. Today, alternative fuels and raw materials (AFR) include a wide range of types of hazardous and non-hazardous waste, as well as solid and liquid, organic and mineral waste.

1 Introduction

To cut the energy cost for clinker production, the German cement industry started substitution of primary fuels with Alternative Fuels (AF) such as used oil or tyres after the first oil shock in the early 1970s. Today, at more than 2 €/GJ energy costs and after establishing a reliable disposal management, alternative fuels and raw materials (AFR) include a wide range of types of hazardous and non-hazardous waste, as well as solid and liquid, organic and mineral waste, which have to be pre-processed, quality-monitored and tailor-made for existing kilns or newly-installed kilns and...

1 Introduction

To cut the energy cost for clinker production, the German cement industry started substitution of primary fuels with Alternative Fuels (AF) such as used oil or tyres after the first oil shock in the early 1970s. Today, at more than 2 €/GJ energy costs and after establishing a reliable disposal management, alternative fuels and raw materials (AFR) include a wide range of types of hazardous and non-hazardous waste, as well as solid and liquid, organic and mineral waste, which have to be pre-processed, quality-monitored and tailor-made for existing kilns or newly-installed kilns and its chemistry of geological survey and products.

For example in Germany the ban on landfill in 2005 pushed the development of technologies for co-processing in the electricity and cement industry. Based on 30 years of proven experience, co-processing is assuming an important role for integrated waste and energy concepts, however in that reduction target on emission of greenhouse gases (GHG).

Therefore almost 50 Mechanical-Biological Treatment (MBT) public plants were installed with an annual input of approx. 6 million tons of municipal solid waste (MSW) and hundreds of small, privately owned plants preselect feasible commercial & industrial waste (C&IW), which have to be subsequently processed into tailor-made residue derived fuels (RDF, < 80 mm) for calciners and quality-monitored solid recovered fuel (SRF, < 25 mm) for main burners.

Realizing in some cases ~100 % thermal substitution rates (TSR), the German cement industry reached a high level of more than 60 % of its thermal demand of about 92 million GJ, which correspond totally with approx. 2 million tons of alternative fuels. Solid, liquid or pasty from hazardous or non-hazardous sources, the feedstock for alternative fuels is different like tyres, meat & bone meal, waste oil or solvents, or production residues (textiles, paper, wrappings, cuts etc.) and biomass have to be pre-treated to meet the requirements regarding handling, dosage, feeding, combustion, process, air pollution and product performance.

The article will focus on the main aspects of pre-processing of waste and co-processing of AF in cement kilns, by identification, waste management, pre-treating and utilization in the cement clinker process with sophisticated processing techniques.

The process of clinker burning has to be assessed with regard to its technical options and defaults. The pre-processing and handling concept within the cement plant as well as the impact of AF on the manufacturing process will be emphasised. Of major importance in this context are pyroprocessing as well as combustion at its point of entrance, impact on product and emission.

2 Initial positions

Due to the continuing energy cost fluctuations and the discussions on the sustainable protection of resources, the German cement industry was able to achieve a continual reduction of its entire power requirement by changing from the wet process to the dry process inclusive preheater tower.

After the first oil crisis in the early 1970s, in order to cut costs a switch was made first from gas and oil to hard coal and lignite, and, due to their high energy content and relatively easy handling, to waste oil and used tyres. Later, this was followed by solvents, oil sludge, wrappings, cuttings and others coming from identified industrial processes.

Single streams of “lignite-like” (Table 1) solid alternative fuels of preselected, production-specific (so called cherry-picked) commercial wastes and biomass and that mentioned liquids were processed to fuel for the main burner, the kiln inlet or – if installed – the calciner. Additionally mineral based residues like filter cake, foundry sand, mill scale or contaminated soil are used for blending to Alternative Raw Materials (ARM) which replaces virgin mineral compounds.

Since it was proved that the use of individually processed wastes had no effect on the emission balance of the plant or on the clinker burning process or the product quality, the wastes may now also be manufactured as blends and used for the energy content as well as the ash content to create clinker, shortly co-processing.

In the meantime, the alternative fuel production and use have been established to the point that especially countries, which are extremely dependent on external energy resources increasingly take into account the integration of waste management into a country-wide energy concept to avoid high public investments into large sanitary landfillings or stand-alone municipal waste incinerators. In order to implement such concepts, naturally also cement plants come into focus. Frequently, however, this makes us forget that cement is a standardised mass product of a highly energy-efficient production process.

The general opinion is that “alternative fuel” still implies cheap “disposal” to the extent that even legislation talks about “co-combustion”. But actually, these are highly complex physical-chemical conversion processes, which have not yet been entirely clarified even with regard to the combustion of coal.

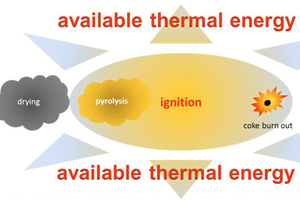

Simplifying combustion as a diffusion controlled combustion process (Fig. 1) it can be described as drying, pyrolysis, ignition and coke burnout in a decreasing oxygen atmosphere. With an increasing TSR, this sequence dominates the combustion and in consequent the entire cement-clinker process.

Usually, commercial wastes and fractions of high calorific value are separately or jointly pre-processed while removing water, metals, glass, ash or other harmful constituents from the fuel.

Therefore, solid alternative fuels with an average lump size of dmax. 300 mm to be fed via kiln inlet or a calciner to the rotary kiln are subject to a different sample preparation procedure and quality management than those fuels, which must be fed via main burner. For a better burnout, these compounds must be comminuted into pieces (dmax. 25 mm or finer) and sifted to avoid reductive burning conditions in the kiln’s sinter zone and still coming to several powers of ten compared to coal dust. If the processing should be finer still, the processing increasingly reaches technical and economic limits.

Normally, in the cement plant, ready to be burnt fuels are transported pneumatically to the respective firing point. Especially, if they are fed via the main burner, the recent inhomogeneous alternative fuel mixtures are differentiated again into individual particle fractions burning at different levels: While thin, large-area particles (e.g. packaging film with a size of 2-500 µm thickness) are consumed by the flame floating, three-dimensional particles (e.g. hard plastic, rubber, wood, etc.), form the tip of the flame or even fly through its ending into the clinker bed or inlet and leading to reductive clinker burning conditions, hot inlet temperature and forming sulphuric cycles.

For these reasons fuel mixtures from dmax.< 25 mm up to 80 mm can be processed mechanically, while large and very large-sized alternative fuels up to 250 mm can be processed thermally.

3 Optimised clinkering zone firing system

If alternative fuels are to be fed via the so-called clinkering zone burner, they must be comminuted to dmax. 25 mm without heavy and 3-D bodies, totally removed for an improved burnout. In order to react appropriately to different fuel properties, the burner must also be designed according to the physical requirements.

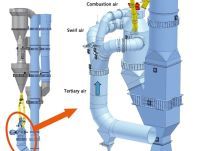

An adopted clinkering zone burner is designed to burn primary fuels as well as SRF with a thermal output of 10 MW to 300 MW and has been especially designed for the use of solid and liquid alternative fuels (Fig. 3). Thus, with a blend of liquid and solid alternative fuels and an average SRF grain size of dmax.< 25 mm it has already been possible to achieve thermal substitution rates of almost 100 %.

During operation, primary air nozzles are selectively adjustable so that any random swirl and divergence are possible and can be adjusted to the flow path of the trajectories of the AF particles. An adapted particle size and intense mixing of fuel and combustion air ensures a quick and complete conversion and significantly shortens the combustion and conversion time in the reaction zone. This behaviour is especially important for hard burning petrol coke or blends of low calorific fuels.

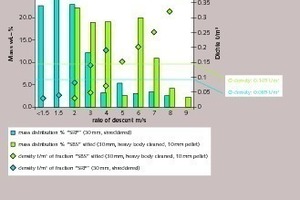

In order to be able to design the burner optimally, the multi-component mixtures of the solid alternative fuels must first be analysed in a classifier and chemically. In the process, the fuel particles separate into particle fractions (Fig. 3, 4), in which the same properties result from equivalent solids of revolution, densities or grain shapes, i.e. the particles move on identical trajectories and will not rain incompletely burnt – like falling stars – into the clinker bed.

Now, this method results in statements regarding the flight behaviour or the quality of pre-processing, the former composition of the waste – single components become clearly perceptible – and the suitability of the fuels particles for the advised feeding point at the rotary kiln. At relevant individual particle fractions, it is now also possible to determine the oxygen requirement or the ignition behaviour at the highest TSR.

4 Mechanical processing

for use in a clinkering zone burner

Regarding the insulating effect, geometry and other surface effects, the diffusions in fuel particles and the combustion speed proceed at different speeds. Mechanically, the diffusion path can be shortened by decreasing the particle size, respectively to enlarge the surface of the fuel particles. For this reason a certain windsifting technology is recommended in the pre-treating process of waste as well, where the SRF will be optimized due to the retention time in the individual body of flame when leaving the mouth of the burner.

This process is perfectly applicable to particles, which are three-dimensional, hard or brittle and so far have led to reductive burning conditions in kiln material. They are separated quickly and effectively, whereby large, but thin two-dimensional flat particles are mostly obtained, which do not affect the combustion with regard to the burnout behaviour. While the amount of heavy, water containing and three-dimensional particles are reduced, the chemical properties of the alternative fuel components remain unchanged.

5 Use of alternative fuels at the calciner

In modern plants with calciners only 40 % of the thermal output is covered by the clinkering zone burner, while 60 % of the thermal heat demand is covered by one or more firing points at the calciner. In the process, the necessary combustion air is fed via the tertiary air duct from the recuperation section of the clinker cooler to the firing points inside the calciner. With regard to reaction, the calciner requires only a temperature of 850-900°C to calcinate the limestone fraction. Inside the calciner, the 1000-1200°C hot flue gases of the rotary kiln and the 800-1000°C hot tertiary air mix, whereby safe ignition and burning are also ensured by slow-reacting, large-sized alternative fuels.

However, especially the burning of various and slow-reacting fuels takes significantly longer time than the preheating and calcining of the raw meal and is consequently the determining factor for the calciner’s dimension. For this reason, various technical solutions for calciners are available. These will allow a control of the combustion temperature and atmosphere so that it is also possible to reduce the NOx emissions.

In order to ensure the burnout of slow-reacting alternative or primary fuels it is not only necessary to support the retension time inside the calciner with a suitable distance required for calcination and burnout but if necessary, by using an additional burning chamber.

For coarse fuels with a very long retention time (Fig. 5), such as biomass, petroleum coke or anthracite, the precombustion chamber is used, where in the centre of a vortex flow and with an initial supply of pure tertiary air high temperatures develop starting drying, pyroprocessing, ignition and burnout. For the use of low calorific, large-sized alternative fuels the retention time in the short hot zone is insufficient. Therefore, a precombustion chamber has been especially developed for the high feed rate of low calorific, large-sized alternative fuels.

The typical retention time of 4-8 seconds in a calciner is sometimes grossly insufficient for the safe burnout of such slow-reacting alternative fuels like high calorific fraction (HCF) with a diameter approx. < 300 mm. Therefore, FLSmidth developed its “Hot Disk” as a turning table integrated with the preheater and calciner systems. It has proven its feasibility for coarse alternative mono fraction fuels made as for truck tires or biomass in sizes up to approx. one metre in diameter.

ThyssenKrupp Industrial Solution developed its “Step Combustor” also added on to the calciner but capable of burning different alternative fuel qualities because the transport and discharge rates are separately controlled by air blast nozzles and no mechanical internal fittings are necessary inside to push over the edge into calciner.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.