A systematic classification and modularization of handling systems for alternative fuels

This article introduces a Seven Stage Concept (SSC), which is a systematic, modular and forward-looking tool that can be valuable for successful realization of plants for handling alternative fuels. The SSC system differentiates between seven handling stages, beginning with the reception of the AF material in the cement plant and ending with its combustion in the rotary kiln.

1 Introduction

Although alternative fuels (AFs) have been used in the cement industry for more than 30 years there has been so far no systematic and analytical approach for the successful handling of these materials. Through ignorance and lack of experience the same mistakes are therefore made time and again in the design of new plants.

Di Matteo Förderanlagen GmbH & Co. KG from Beckum in Westphalia has carried out some pioneering work in the field of handling alternative fuels and, among other things, has also developed measuring procedures and investigative methods for evaluating the...

1 Introduction

Although alternative fuels (AFs) have been used in the cement industry for more than 30 years there has been so far no systematic and analytical approach for the successful handling of these materials. Through ignorance and lack of experience the same mistakes are therefore made time and again in the design of new plants.

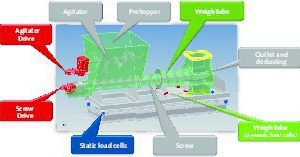

Di Matteo Förderanlagen GmbH & Co. KG from Beckum in Westphalia has carried out some pioneering work in the field of handling alternative fuels and, among other things, has also developed measuring procedures and investigative methods for evaluating the mechanical characteristics of these bulk materials that are often characterized by extreme properties. The SSC system (Seven Stage Concept) described here is a systematic, modular and forward-looking tool that can be valuable for successful realization of plants for handling alternative fuels. The SSC system differentiates between seven handling stages, beginning with the reception of the AF material in the cement plant and ending with its combustion in the rotary kiln. Di Matteo contributes a great deal of mechanical equipment to the SSC system. The company has become particularly well known through its tubular weighing system – the WeighTube. The tubular weighing system consists of a tubular screw conveyor that is fed via an agitator and to which is attached a weigh tube. This rests on dynamic load cells and carries out the weighing so that the AF material can, for example, be transferred to a pneumatic conveyor for onward transport to the rotary kiln burner. Di Matteo can point to numerous successfully implemented systems in the cement industry, in Germany and abroad.

2 Use of alternative fuels

For the majority of cement plants worldwide the use of solid alternative fuels, referred to below as AFs, is of considerable importance for cost-effective and sustainable plant operation. In general, the efforts are now no longer looking just to achieve a low thermal substitution rate but are aimed at sustainable improvement in availability and raising the substitution rate to 100 % to achieve long-term cost and competitive advantages. In fact, there have already been many years of experience with the use of numerous alternative fuels, sometimes of widely differing types, such as the fuels known by the abbreviations SBS, RDF, SRF, MSW, containing industrial and municipal waste, biomass, fluff, etc. However, there are very often still substantial problems with the handling of these materials. Problems are often caused by lack of understanding of the relevant bulk material properties or through the use of unsuitable plant components for the particular application. Solid alternative fuels differ substantially from conventional classical bulk materials [4, 5]. A fundamental understanding of the bulk material properties is just as much an essential requirement for optimum and successful handling as the choice of the correct plant components.

3 Characterization of alternative fuels

Accurate knowledge not only of the physical bulk material properties but also of the chemical and thermal properties is important for comprehensive characterization of AFs (Figure 1). This article examines the physical properties as these are relevant for the thermal utilization of AFs in rotary cement kilns [6, 7].

Analytical characterization of AFs should always be considered against the background of their thermal utilization in rotary cement kilns. For all alternative fuels the thermal utilization, i.e. the combustion of AF in the main burner, the kiln inlet or in the calciner, takes place basically as shown in the diagram in Figure 2.

Against this background it is clear that optimum combustion can only be achieved if the fuel is introduced into the process with the largest possible specific surface area and with the parameters required by the combustion process. However, this means that the material to be burnt must not be compacted or compressed during the preceding handling as this causes substantial disruption to the kinetics of the burning process and can retard them. Some important physical properties of selected AFs are listed in Table 1. Because of different production processes and process engineering handling stages this can only provide indicative information that must be checked and verified in the specific instance as otherwise considerable discrepancies may occur. It must also always be borne in mind that the bulk material properties of AFs are not constant over time. For example the bulk density can, depending on the type and duration of storage, change substantially due to the action of external forces during the storage of AF.

In general, the following physical bulk material parameters are of fundamental interest:

Bulk density

Particle size distribution

Wall friction angle

Internal material friction

Horizontal stress behavior

Consolidation with time

Compressibility

Explosion parameters

These bulk material parameters cannot be determined with the familiar available methods so Di Matteo has developed suitable methods of measurement and measuring equipment with which the requisite physical bulk material properties can be determined. It is now possible, for example, to measure the compressibility behaviour as well as the time consolidation in the plant’s own research centre with measuring equipment developed in-house.

4 Frequent problems in the utilization of AF

Problems that occur frequently during the handling of AF will be indicated below using the examples of storage and metering. Intermediate storage in operational plants is unavoidable when using large quantities of material. Various aspects have to be considered when choosing a suitable storage system. Defining a requirement profile for a fuel store basically gives rise to two categories (Table 2).

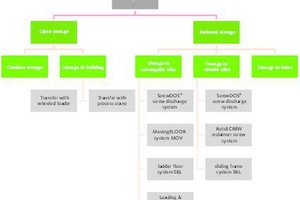

The familiar types of storage used for other conventional bulk materials are also theoretically possible for storing AFs [4, 5]. However, experience shows that because of the specific bulk material properties of AFs, which can change greatly over the storage time, only a few types of storage can be used successfully. The different types of storage can be classified meaningfully using the outline in Figure 3. When the types of storage listed in Figure 3 are considered in the light of the specific bulk material requirements given in Table 2 it is advantageous for large silo volumes to aim for the FIFO principle (first-in-first-out) to avoid time consolidation and compression of the AF. As an example, the use of a LUC loading and unloading reclaimer will be compared with a MOV moving floor system. Both systems are produced and installed by Di Matteo. However, the advantages and disadvantages of the respective systems should always be weighed against one another for the particular application.

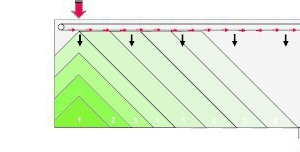

When a LUC loading and unloading reclaimer is used the material is deposited as shown in Figure 4. Depending on the silo size/store height, storage time and the properties of the AF, such as particle texture, particle size and moisture, the material consolidates mainly in the lower region just through its own weight. In this system the AF is reclaimed from the top so that the material that is deposited first is reclaimed last. This storage and extraction system operates on the LIFO principle (last-in-first-out). Problems caused by the system that have negative effects on the combustion process can therefore be expected with an AF with a high moisture content and long storage times.

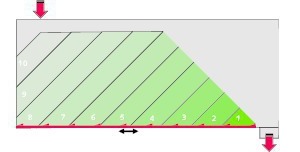

Figure 5 shows the material flow for the MOV moving floor system. Depending on the silo size/store height, the storage time and the properties of the AF material, consolidation can also occur here in the lower region. In contrast to the use of a LUC loading and unloading reclaimer, the extraction in the MOV moving floor system is produced by the horizontal movement of the entire volume of material in the direction of the outlet. This corresponds to the FIFO principle (first-in-first-out) and means that material flow problems caused by the system are not to be expected, even when using an AF material with high moisture content and long storage times. Furthermore, thorough mixing of different material layers occurs in the outlet area, which leads to better homogeneity of the AF material and assists the subsequent combustion process.

Different aspects from those that occur during storage play a role during metering of AF (Table 3). For example, it is now expected that a metering system for AF should be enclosed to meet the current Health and Safety requirements. The metering system must also be suitable for the greatest possible range of AF materials with widely varied properties. The well-known belt weighfeeder and the weighing screw conveyor are compared below with the novel WeighTube tubular weighing system. All three systems are produced and installed by Di Matteo. The advantages and disadvantages of the respective systems should be known and taken into account when decisions are made about their use.

The metering systems shown in Figure 6 – the belt weighfeeder (Figure 6a) and the weighing screw (Figure 6b) – are still used. The belt weighfeeder is the correct choice if it is a question of metering AF that is very coarse or has a large surface area, such as shredded tyres or SRF for firing the calciner. Regardless of the particular detailed design, the disadvantage is that the belt weighfeeder is, in principle, an open system. The weighing screw (Figure 6b), in which the entire screw is supported on load cells, is now an outdated weighing system that is completely unsuitable for reliable metering of lightweight AF materials with bulk densities of less than 500 kg/m³. As a rule AFs always involve bulk materials that have some very corrosive and abrasive properties, so this requires the use of mechanically robust machines. The use of a weighing screw entails the problem that the very high tare weight of the machine is contrasted with the relatively low net weight of the AF material. In practice, this means that when a weighing screw is used it can only operate as a volumetric metering system.

Against the background of the two metering systems described above, Di Matteo decided to develop a metering system that combines the advantages of the two metering systems shown in Figures 6a and 6b. This resulted in the WeighTube tubular weigher (Figure 7). This involves a fully enclosed system that has solved the problem of the unfavourable tare/net weight ratio in that only a short section of the casing is weighed on load cells. The structural arrangement of the feed hopper, the agitator and the metering screw avoids any compaction of the material and also ensures that any agglomerates that may be present are destroyed, which is an advantage for the subsequent thermal utilization of the AF material. The novel Weigh Tube tubular weighing system has already proved successful in many applications around the world for metering AFs as well as conventional bulk materials [10–13].

5 The SSC system –

systematic classification of plants for handling AFs

As already indicated above, there are usually several alternative solutions for handling AFs. The problem is that the choice of the wrong plant component for the particular task at the design stage can mean the failure of the entire investment or, at the least, cause considerable worsening of the expected return on investment. Di Matteo has therefore developed the SSC – a Seven Stage Concept (Figure 8).

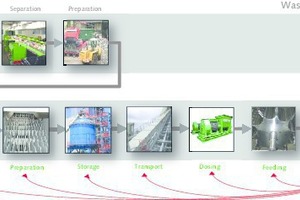

Every plant for thermal utilization of AF can basically be subdivided into seven stages:

1. Reception

2. Preparation (e.g. protective screening)

3. Storage

4. Transport

5. Metering

6. Feeding to the kiln process

7. Combustion

Depending on the given or expected physical properties of the AF there are several alternatives available for technical implementation of each stage. During the systematic and purely analytical development of a complete plant for handling AF the optimum plant design for the individual client is worked out with the aid of appropriate choices. The most important aspect in the choice of plant components is the consideration of the ultimate thermal utilization of the AF from the point of view of avoiding compaction and formation of agglomerates that are detrimental to combustion.

This approach offers several advantages over haphazard and unsystematic plant design:

Only tried and tested plant components are permitted in the SSC system.

The advantages and disadvantages and the limits of use for the different AFs are laid down for each plant component so that the use of plant components for the wrong tasks is avoided.

Because of a wide product portfolio all the current and proven alternative plant components for solving the particular problem can be offered without bias within the framework of the SSC system.

As a modular system the SSC system offers the opportunity for ongoing systematic extension by the addition of new plant components. The individually optimized plant design can be given a modular configuration with maximum flexibility for the client.

All plant modules are designed, manufactured and installed by Di Matteo so that the client obtains everything from a single source.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![2 Sequence of combustion during conversion of solid alternative fuels [8]](https://www.zkg-online.info/imgs/tok_9914c1c6bfb5072c5c2e8902d3e4658e/w300_h200_x400_y203_101551212_067771cbad.jpg)