Alternative fuels handling system

at a cement plant in Turkey

This case study presents a typical system for material handling installed at a cement plant in the northern part of Turkey. Customized Refuse Derived Fuel (RDF) is delivered in compressed bales and will finally be used in the calciner to reduce the consumption of conventional fossil fuels.

FLSmidth is a leading provider of cement know-how and equipment with more than over 130 years of combined knowledge of the entire value chain from source to product and also emissions. With 25 years of dedicated experience FLSmidth also offers solutions for dosing and handling of solid alternative fuels and shows the industry a comprehensive portfolio of technologies, which excels in creating unique systems tailored to the specific requirements of any clients.

This case study shows a typical example of such a material handling plant installed at a cement plant in the north of Turkey. Here...

FLSmidth is a leading provider of cement know-how and equipment with more than over 130 years of combined knowledge of the entire value chain from source to product and also emissions. With 25 years of dedicated experience FLSmidth also offers solutions for dosing and handling of solid alternative fuels and shows the industry a comprehensive portfolio of technologies, which excels in creating unique systems tailored to the specific requirements of any clients.

This case study shows a typical example of such a material handling plant installed at a cement plant in the north of Turkey. Here Refuse Derived Fuel (RDF) is delivered in compressed bales and is finally burnt in the calciner to reduce the consumption of conventional fossil fuels.

After automatic bale opening, the RDF reaches a double-shaft screw conveyor which doses the RDF into an inclined KOCH® Drag Chain Conveyor feeding a 1250 m³ capacity storage box. The layout of the plant allows the addition of more identical storage boxes at a later stage in order to increase the storage capacity.

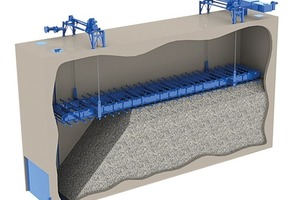

FeedexTM overhead reclaimer

The Feedex overhead reclaimer (Fig. 1) is a storage system for solid alternative fuels and biomass which is hanging inside a bunker made of concrete. The reclaimer is suspended by round link chains from two independent hoisting winches located at the top of the bunker. Thus the Feedex can be lifted and lowered following the material level inside the bunker. As a result the Feedex ensures full utilization of the storage space, optimum distribution and homogenization of fuel within the bunker as well as the discharge of fuel to the downstream conveyor. In the case that more than one storage is available, different types of fuel with different specifications can be blended from each bunker in order to achieve the required homogeneity, and to reduce fluctuations of the calorific value and other properties to ensure a smooth combustion process. The system operates from the top thus providing a much better reliability and lower energy consumption than systems working from the bottom of the bunker.

The Feedex conveys the RDF to a double-shaft screw conveyor installed at the bunker outlet. The variable speed drive of the screw conveyor allows dosing the RDF to the following KOCH Drag Chain Conveyor which feeds the material to the FLSmidth Pfister Rotor Weighfeeder.

The FLSmidth Pfister Rotor Weighfeeder precisely doses the RDF for the subsequent process. For the transfer of the fuel through the plant from the storage area to the calciner tower a KOCH Pipe Conveyor has been installed as it can be easily integrated into existing facilities. The pipe conveyor was selected because of its key benefits which include its ability to accommodate unique curves, bypass buildings, cross roads and other infrastructures and provide dust-free, long-distance transport of alternative fuels.

The KOCH Pipe Conveyor®

The KOCH Pipe Conveyor is a closed belt conveyor system which conveys the RDF over the complete distance (Fig. 2). In order to receive the material, the belt has an open loading area similar to a conventional belt conveyor.

After feeding the RDF to the conveyor belt, special rollers form the KOCH Pipe Conveyor into an enclosed hose which permits horizontal, vertical and also 3-dimensional curves, avoiding additional transfer towers and closed conveyor gantries. Due to its transport principle (Fig. 3) the conveyor is able to achieve steep inclination angles significantly exceeding the limits of a conventional belt conveyor. Other benefits to choosing a KOCH Pipe Conveyor is the protection of the environment from dust emissions and odors as well as protecting the RDF against additional humidity.

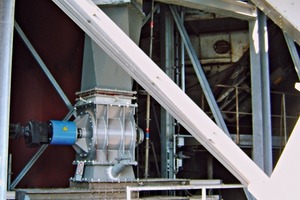

Calciner feeding system

The Pipe Conveyor feeds the fuel to a downstream drag chain conveyor, ending in front of the combustion chamber. A combination of a rotary feeder and a triple slide gate system (Fig. 4) provides protection against high temperatures and keeps the process conditions inside the calciner unchanged.

From the automatic bale opener up to the calciner tower FLSmidth accomplished a “One Source” service solution for alternative fuels handling.

In addition, FLSmidth is your viable partner to define the process implications and optimization of your system when firing alternative fuels.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.