Smart storage of solid alternative fuels

Cement producers are exposed to unceasing economic and ecological pressure to both reduce fuel costs and cut CO2 emissions...

Cement producers are exposed to unceasing economic and ecological pressure to both reduce fuel costs and cut CO2 emissions simultaneously. As a result, operators are using ever larger quantities of alternative fuels (AF). The fact that the widespread use of AF is a “must”, given current prices for primary fuels, became clear long ago. Ever higher thermal substitution rates are also motivating cement plants to temporarily store continuously increasing amounts of the necessary alternative fuels, in order to assure uninterrupted kiln operation. It must be possible to balance out weekends and public holidays, on which no additional fuel can be delivered, by means of appropriate storage capacity, a criterion which thus dictates the dimensioning of the corresponding storage facilities.

Many European cement plants obtain the large amounts of solid alternative fuel needed from a range of different suppliers. In other parts of the world, on the other hand, cement producers are frequently confronted with the problem that a continuously high supply of one and the same alternative fuel cannot be assured at all, as a result of either infrastructural or financial restrictions. The almost inevitable consequence is that such plants are exposed to quality fluctuations in their fuel. For all operators, a constant quality and continuous supply of SRF1 to the rotary kiln and/or RDF2 to the calciner are important factors in assuring a continuing production process. The implementation of a sophisticated and flexible storage system which meets the need of blending and supplying a fuel of a quality as constant as possible is therefore essential for cement plants.

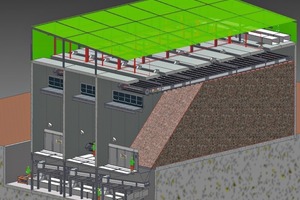

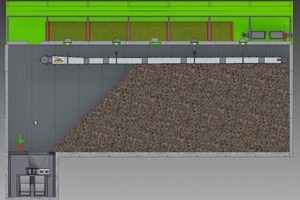

To assure the cost-efficiency of such a storage facility, it must provide the largest possible storage capacity on the lowest possible storage area, with a simultaneously high throughput rate for input to and reclamation from storage (Fig. 1, 2). Vecoplan FuelTrack’s loading and unloading system (BEF-System) meets these requirements. These storage systems have been in use since as early as the 1970s. Initially designed only for wood products, it quickly became apparent that they were also suitable for storage of various other materials, such as solid alternative fuels, for example. More than 300 of these systems have now been installed around the world for the storage of the most diverse range of materials.

This storage system has proven its capabilities in cement plants, for operation using solid alternative fuels, and is even suitable, for use in explosion-endangered ATEX zones. The system has been continuously refined and optimized: the latest generation, for example, includes not only a redesigned drive mechanism with enhanced control and regulation performance, but also significantly improved lateral stability of the distribution conveyor system. In addition, a new and more maintenance-friendly box design with new maintenance platforms enhances operating reliability and expands the system’s potential applications even further. In this BEF-System the distribution conveyor, (Fig. 3) used for both input and reclaiming is suspended by steel cables from the storage facility roof. Recirculating dogs borne on chains assure a spreading of the RDF during input and a removing during reclaiming.

During input, the material is deposited in layers from the bottom upward (Fig. 4). “Fluffy” solid alternative fuel has the property of compacting under pressure (weight exerted from above). Something which causes reclaiming problems in many other storage systems proves in the BEF to be a benefit: layer by layer input and the thus rising deadweight of the fuel causes a self-compacting. Such self-compacting can significantly increase the theoretical capacity of a storage box. Recent measurements performed on such BEF-Systems in Southern Germany indicated real capacities of up to 2000 m3 per storage untit for a box that was designed for a geometrical volume of approx. 1000 m3.

In operation with only a single or two BEF-Systems, the storage can also be fed by using conveying screws, although input is accomplished using drag-chain conveyers in most cases. Input of material by using drag chain conveyers is, in fact, recommendable, in order to assure flexibility in case of future expansion. The correct distribution of the various materials to their individual boxes is achieved by a slide gate located below the drag chain conveyor, which open or close a filling hopper above the particular target box.

Since both input and reclaiming of material is effected using the scraper arrangement operating from above, the BEF-System also has the advantage that the total weight of the stored material does not act on the extraction conveyor. This generates the enormous benefit that the force required for reclaiming of material can be kept low, since only the uppermost layers, not subjected to weight-pressure, are extracted. The fuel slides at the angle of repose occurring during input into an intermediate hopper located below the system. From here, the solid alternative fuel is systematically metered by frequency-controlled conveying screws onto a drag chain conveyor. Simultaneous reclaiming from multiple boxes in sequence thus permits blending and/or homogenization of the various grades.

Material input and reclaiming can be performed in parallel. It is also possible to divert the material just arriving in storage directly to the extraction point. This process operates fully automatically and can be controlled at all times from the control panel. The various flows of material can thus be blended from all available boxes, on the basis of their quality properties, to form a single conveyed flow.

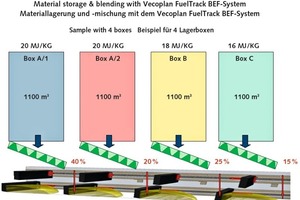

Figure 5 illustrates the principle of metering and blending of differing processed alternative fuel grades. The way a stable fuel mix suitable for the kiln process can be generated fully automatically from differentiated alternative fuels with differing properties and, above all, differing calorific values, is apparent here.

For operation with solid alternative fuel, the storage system is completely sealed, making an additional dedusting system unnecessary as well as also the significant concomitant investment and operating costs. The storage boxes are completely structurally separated from one another, making it possible to inertize them individually in case of fire. This minimizes the risk of fire spreading to the entire stock of fuel.

The storage system can be configured on a modular basis, in order to keep the investment costs low for the entry into the AF-handling. The storage capacity can then later be expanded by adding additional boxes. Any number of storage boxes can, in theory, be installed to operate in parallel.

This modular structure permits an ideal material flow management with the ability to react flexibly to the most diverse range of material flows while nonetheless adapting to meet the needs of a continuous production process.

The benefits of the system at a glance:

Self-contained storage boxes

Modular structure

No high-cost dedusting installation needed

Maintenance platform for optimal access

Robust scraper system

Capability for storage of differing materials

Easy and flexible blending of solid alternative fuels

Storage capacity boosted by self-compacting

Low extraction forces, thanks to removal of material from the top down

Automatic level sensors

Storing and discharging simultaneously possible

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.