Study on mechanical strength and early hydration properties of cement paste modified by polycarboxylate superplasticizer with slump retention

The polycarboxylate superplasticizer with slump retention capabilities (PCE-SR) may significantly enhance concrete cohesiveness and construction performance because of its high water reduction rate and outstanding slump retention. In order to explore the effective mechanism of PCE-SR on cement paste, this paper investigates the influence of PCE-SR on the mechanical strength and microstructure of hardened cement. The results indicate that PCE-SR might effectively reduce cement water usage and the water reduction rate by as much as 30%. With the addition of PCE-SR, the mechanical strength of hardened cement paste was improved and the hydration process and hydration heat were reduced. In addition, the microstructure of hardened cement paste might be enhanced with PCE-SR added due to reduced porosity of the hardened specimens.

1 Introduction

Concrete and cement-based materials are the primary foundations for the capital construction of a country due to their widely used and large consumption [1]. High-performance concrete, which has superior workability, mechanical strength, and durability, is the inevitable direction of technology development as science and technology advance [2-3].

In order to improve the workability and the mechanical strength of cement-based materials, concrete additives, especially superplasticizers, have become an indispensable part of concrete engineering [4-5]. Currently, the polycarboxylate...

1 Introduction

Concrete and cement-based materials are the primary foundations for the capital construction of a country due to their widely used and large consumption [1]. High-performance concrete, which has superior workability, mechanical strength, and durability, is the inevitable direction of technology development as science and technology advance [2-3].

In order to improve the workability and the mechanical strength of cement-based materials, concrete additives, especially superplasticizers, have become an indispensable part of concrete engineering [4-5]. Currently, the polycarboxylate superplasticizer (PCE) is widely employed in high-performance cement-based materials because of the designability of its molecular structure, which can adjust to diverse performance needs [6-8]. The impact of PCE on the cement during hydration and hardening has been the subject of extensive research. The results show that many properties, such as fluidity [9], mechanical strength [10], and durability [11], were improved when cement-based materials were affected by the PCE. It is well-known that the electrostatic repulsion and steric hindrance effect created by adsorption on the surface of cement particles or hydration products play a significant role in how PCE disperses and plasticizes when applied to cement-based materials [12-15].

However, PCE used in construction faces the problem of the diversified raw materials, the long transportation distance and varied climates. The functional PCE, especially the polycarboxylate superplasticizer with slump retention capability (PCE-SR), has become the research focus [16-18].

In this work, PCE-SR was used to lower the water-to-cement ratio (w/c) and increase the fluidity and mechanical strength of the cement. The fluidity of cement paste and w/c were measured to determine the rheological properties. Compressive and flexural strengths were tested to determine the mechanical strength of cement. The adsorption behavior and microstructure were characterized to evaluate the effect of PCE-SR on the cement. These findings could be an essential guide for making pumped and high-performance concrete, particularly superfluid self-compacting concrete, in real-world engineering applications.

2 Materials and methods

2.1 Materials

2.1.1 Cement

Ordinary Portland cement (P.O 42.5, supplied by China United Cement of Luoyang Co., Ltd., China) was used in this research following Chinese standard GB/T 8077-2012. The chemical compositions obtained with an X-ray fluorescence spectrometer (Axios advanced) are shown in Table 1, and the basic information obtained from the company is shown in Table 2.

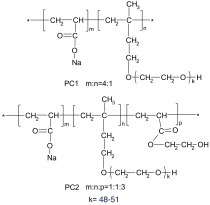

2.1.2 Polycarboxylate superplasticizer with slump retention capability

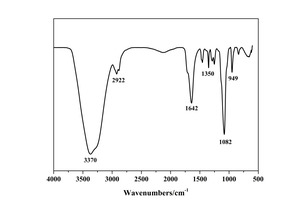

This study used a self-prepared polycarboxylate superplasticizer with slump retention capability (PCE-SR), a translucent liquid with a solid content of 40%. The pH of PCE-SR was weakly alkaline. The functional groups of PCE-SR characterized with Fourier-transform infrared spectroscopy (FTIR, Nexus, USA) are shown in Figure 1 and Table 3 [19].

2.2 Test methods

2.2.1 Fluidity

The fluidity test meeting the requirements of Chinese standard GB/T 8077-2012 was carried out to investigate the effect of PCE-SR on the cement paste. Cement and the PCE-SR solution (0~1.0 wt%) were mixed evenly with the same water/cement ratio (0.40). The average of the maximum diameter and width perpendicular obtained by a mini-slump cone (with a height of 60 mm, top diameter of 36 mm, and bottom diameter of 60 mm) was considered the fluidity value.

2.2.2 Adsorption behavior

The adsorption behavior of PCE-SR in the cement system was analyzed by the total organic carbon analyzer (TOC, Liquid TOC II Germany). PCE-SR solutions with a concentration of 0~10.0 g/l were prepared in advance, and the 1.0 g cement was mixed in 10 g PCE-SR solutions by a magnetic stirrer. The mixture was thoroughly stirred for 5 min and then centrifuged by the TDL-80-2B centrifuge (Shanghai/China) at 3500 r/min for 5 min to obtain upper supernatant, which was prepared for the TOC measurement [20-21].

2.2.3 Compressive strength

The mechanical strength of hardened cement specimens was measured by a fully automatic test machine (TYE-300, China) following the Chinese standard (GB/T 17671-2021). Each sample for the compressive strength test was cast into a 40 mm×40 mm×160 mm vessel. The loading rate of the compressive strength and flexural strength tests were 2.4 KN/s and 50 N/S, and then the compressive to flexural strength ratio could be calculated.

2.2.4 Hydration heat analysis

The 8-channel microcalorimeter (TAM Air, America) was used to investigate the heat release during the cement hydration process. The test was carried out with the temperature range from 5 to 90 °C.

2.2.5 XRD analysis

The X-ray diffractometer (Ultima IV, Rigaku) was used to investigate the phase composition of early hydration products. The test was carried out with the scanning rate of 10°/min and 2-theta degree ranging from 10°-80°.

2.2.6 SEM analysis

The scanning electron microscope (TESCAN MIRA LMS, Czech) was used to investigate the micromorphology of hardened cement specimens. The test was conducted with the accelerating voltage of 10-15 kV.

3 Results and discussion

3.1 Fluidity

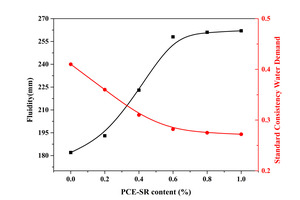

Figure 2 shows the fluidity of cement pastes with different PCE-SR contents. It can be seen that the fluidity of cement paste with the PCE-SR content ranging from 0.2% to 1.0% was increased by 8.24%, 22.53%, 41.76%, 43.41% and 43.96% compared to the specimens without the addition of PCE-SR with the same water-cement ratio (w/c). The standard consistency water demand of cement paste decreased with the increase of PCE-SR content, reduced by 12.20%, 24.39%, 31.22%, 32.93% and 33.66%. Adding PCE-SR effectively increases fluidity and reduces the w/c under the same cement consistency [22].

3.2 Adsorption behavior

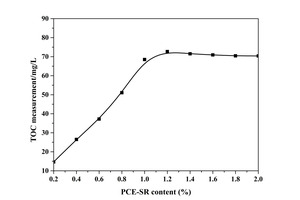

In order to explain the increase of cement fluidity of cement with the addition of PCE-SR, the adsorption of PCE-SR was studied with TOC, and the results are shown in Figure 3. It can be seen that PCE-SR can absorb on the surface of cement particles. With the increasing addition of PCE-SR, the adsorption capacity increased linearly at first and then kept stable after the content of 1.0%. The functional groups in the structure of PCE-SR, including -OH, -CH, -COOH and C=C, can be reacted with Ca2+ to form a calcium-based compound and then absorbed on the surface of cement particles to disperse the paste during cement hydration. Thus, the double action of chemical and physical adsorption of PCE-SR in the cement hydration process is a fundamental reason for improving cement paste fluidity [23].

3.3 Mechanical strength

The mechanical strength of cement with different contents of PCE-SR is shown in Figure 4. As shown in Figure 4 (a), the 7 d compressive and flexural strength of cement with a PCE-SR content ranging from 0.2% to 1.0% was first raised and subsequently significantly lowered. The maximum value of 7 d compressive and flexural strength of cement hardened with 0.6% PCE-SR addition is 44.98 MPa and 7.90 MPa, respectively. Similarly, adding 0.6% PCE-SR increases the maximum value of 28 d compressive and flexural strength of cement hardened to 65.05 MPa and 12.26 MPa, respectively (shown in Figure 4 (b)). Compared to cement without the addition of PCE-SR, the addition of PCE-SR can significantly increase the mechanical strength of cement. The flexibility of cementation materials was assessed using the compressive-to-flexural strength ratio. The cement is less flexible because of the hydration products. However, because the hydration products remained the same, the addition of the PCE-SR did not significantly alter the flexibility of cement.

3.4 Hydration heat analysis

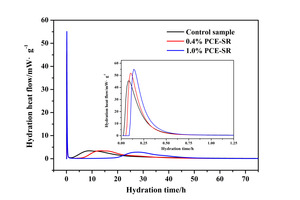

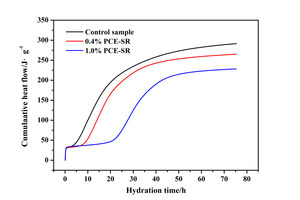

It is known that the hydration process of cement mainly can be divided into three periods: ettringite formation, hydration of tricalcium silicate (C3S) and structure formation and development. The formation of ettringite (Aft) is the main reason for the first exothermic peak. The second exothermic peak is formed due to the rapid hydration of C3S [24-25]. Hydration exothermic rate and cumulative heat of cement pastes with different contents of PCE-SR are shown in Figure 5. As shown in Figure 5 (a), compared with hydration heat flow curves of the control sample, the period of ettringite formation and hydration of C3S of cement pastes were delayed with PCE-SR added, and with the content of PCE-SR increasing, the above extension phenomenon became significant. The exothermic peak values of hydration heat curves are shown in Table 4. With the added PCE-SR increasing from 0.4% to 1.0%, the hydration heat flow of the ettringite formation period increased from 51.8 mW·g-1 to 55.11 mW·g-1, while the hydration heat flow of hydration of the C3S period decreased from 3.43 mW·g-1 to 2.84 mW·g-1. As shown in Figure 5 (b) and Table 4, it can be seen that with the hydration time prolonged, the increase in cumulative heat flow of cement pastes continued. However, the cumulative heat flow decreased with the content of PCE-SR increasing.

The main reason for the delay in the cement hydration process is that the dissolution of cement particles and the diffusion of ions in the pore solution were hindered due to the adsorption of PCE-SR on the surface of cement particles, and the crystallization process of hydration products was also inhibited.

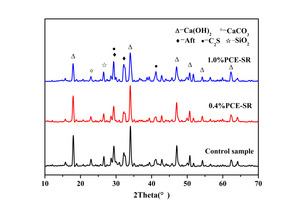

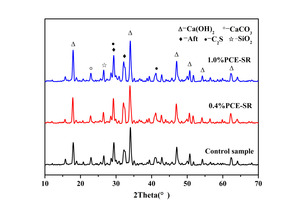

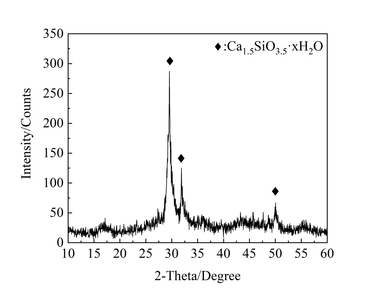

3.5 XRD analysis

As mentioned above, the fluidity of paste and the mechanical strength of specimens are affected by contents of PCE-SR. The crystal phase of specimens with different contents of PCE-SR were investigated by XRD to characterize the mineral composition of hydration products [26-27].

XRD patterns of specimens are shown in Figure 6. It can be seen that the cement minerals such as C2S and C3S and the main hydration products such as Ca(OH)2 and ettringite existed at an early hydration age (within 7 d). This is due to the low degree of early hydration of cement and incomplete hydration of clinker minerals. As shown in Figure 6 (a), at 3 d the intensity of the Ca(OH)2 peak decreased with the addition of PCE-SR more than that of the control sample, suggesting that the addition of PCE-SR delays the hydration process of cement and the formation of hydration products is relatively slow. On the contrary, the intensity of the Ca(OH)2 peak increased with the addition of PCE-SR more than that of the control sample at 7 d, indicating that with the addition of PCE-SR the dispersion of cement gains is improved and the hydration reaction is sufficient.

Based on the phase analysis of specimens, the hydration products formed by the addition of PCE-SR were characterized qualitatively, which can reveal the reason for the effect of PCE-SR on the hydration process of cement.

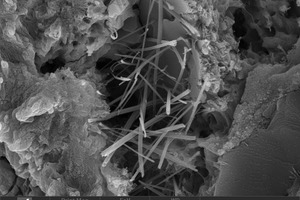

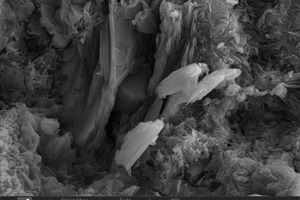

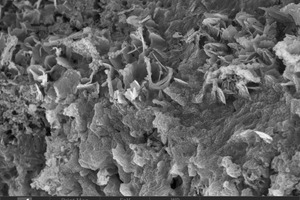

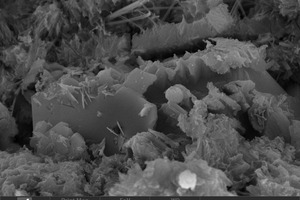

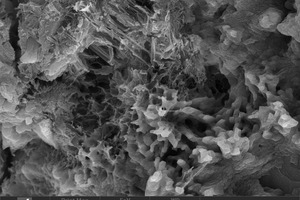

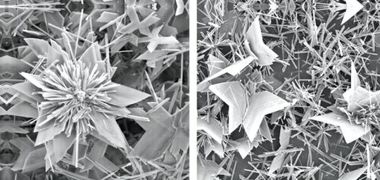

3.6 SEM analysis

The influence of PCE-SR on the microstructure of hydration products was investigated using SEM, and the mechanism by which PCE-SR affects cement characteristics was then thoroughly described.

Figure 7 shows the SEM images of specimens with different contents of PCE-SR. Figure 7 (a) shows the network structure of the hydration products of the control sample. The hydration products of calcium hydroxide, ettringite and C-S-H gel are interconnected to form the network structure. However, due to the high w/c, the network structure is relatively loose, containing relatively large pores among the hydration products, which is the main reason for the relatively low strength.

SEM images of specimens with various contents (0.2%, 0.4%, 0.6%, 0.8% and 1.0%) of PCE-SR are shown in Figure 7 (b-f). Although the cement hydration included the same hydration components, the w/c decreased as PCE-SR contents increased. The compactness of the network structure and the mechanical strength were increased with the PCE-SR content ranging from 0.2% to 0.6%. The network structure is damaged by internal stress when the PCE-SR content exceeds 0.6% because of the saturation point for PCE-SR adsorption on the surface of cement particles [27]. During the hydration process, excessive PCE-SR would cause slurry segregation, reducing the strength of the hardened specimens.

4 Conclusion

Based on this research, PCE-SR was used to increase the mechanical strength and improve the microstructure of hydration products. The results of this study can be summarized as follows:

Due to the chemical and physical adsorption of PCE-SR, PCE-SR can improve the fluidity of cement paste and reduce the w/c under the same cement consistency. When PCE-SR content was over 0.6%, the fluidity change and w/c were not obvious. The fluidity of the cement paste was over 260 mm, and the w/c under the same cement consistency was less than 0.28.

The mechanical strength of cement can be improved by adding the PCE-SR. With the addition of PCE-SR, the compressive and flexural strength increased significantly compared to the control sample. The change of mechanical strength growth increases first and then decreases slightly with the increase of PCE-SR contents. When PCE-SR content is 0.6%, the maximum relative growth rate of compressive strength at 7 d and 28 d is 34.87% and 15.79%, and the maximum relative growth rate of flexural strength at 7 d and 28 d is 24.80% and 10.45%.

With the addition of PCE-SR, the hydration process and hydration heat reduces, the w/c decreases, and the compactness of the network structure increases, resulting in the improvement of the mechanical strength of cement.

Acknowledgment

The authors acknowledge the financial support from National Natural Science Foundation of China (52102024) and National Natural Science Foundation of Henan Province (202300410284).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.