RubberCrete: A rubber based concrete system with superplasticizer and graphite nano particle-rheology, strength, shrinkage, and durability features

Scrap tires pose a severe environmental threat as current disposal practices of landfill storing or mass burning lead to extensive soil pollution and carbon dioxide production. As opposed to disposing, recent studies have made efficient progress in salvaging this material for use in abundantly produced concrete mixes. The present study contributes to this continuous effort by investigating the use of recycled rubber gravel from scrapped tires as a substitute for natural fine gravel in self-compacting composite (SCC) mixes. A total of six SCC mixtures were considered for testing in which fine gravel was substituted for different recycled rubber gravel contents of 0, 5, 10, 15, 20 and 30% by volume of sand and graphite nano particle was inserted by percentages of mass of cement – 0.01, 0.02, and 0.03. The comprehensive examination of concrete material properties includes workability, rheological properties, mechanical properties, thermal conductibility, shrinkage, water absorption, and penetration behavior water and chloride ions. The results indicate an optimal rubber content of 15% for efficient workability while also being a limiting rate for rheological characteristics. The properties of thermal conductibility, water absorption, and water penetration were notably enhanced with an increase in rubber content. In contract, a negative impact on both mechanical properties and chloride ion penetration were observed for SCC incorporating rubber content. Overall, the current investigation produces further insight into multiple pertinent properties of rubberized SCC while also addressing several limitations presented in the literature.

1 Introduction

An abundance of industrial waste is produced at alarming rates which fuels the demand for efficient recycling processes. Such efforts would allow waste material to be repurposed as substitutes to natural resources leading to sustainable practices. One of the most profusely available waste is scrapped tires in which an estimated one billion tires are discarded every year with a projected growth of five billion tires by 2030 [1, 2]. Scrapped tires are often thrown into landfills every year resulting in soil, water, and air contamination. Tires also contain toxic and soluble...

1 Introduction

An abundance of industrial waste is produced at alarming rates which fuels the demand for efficient recycling processes. Such efforts would allow waste material to be repurposed as substitutes to natural resources leading to sustainable practices. One of the most profusely available waste is scrapped tires in which an estimated one billion tires are discarded every year with a projected growth of five billion tires by 2030 [1, 2]. Scrapped tires are often thrown into landfills every year resulting in soil, water, and air contamination. Tires also contain toxic and soluble substances which result in soil pollution at landfill sites [3, 4] which causes further detriment given that waste rubber material is not bio-degradable [5]. Alternatively, when discarded tires are burned, they result in severe air pollution in which a single ton of tires releases over a ton of carbon dioxide. Thus, an effective waste management system for rubber sourced from scrapped tires carries great potential to be reused in alternative industries. One such candidate is the construction industry which consumes immense quantities of natural resources and energy [6]. In recent years, the construction industry has been contributing to the recycling of used tires by using them in soil and embankment stabilization and reinforcement as well as alternative fuel in cement kilns [1]. A more influential adoption of recycled rubber in concrete mixes has incited remarkable attention and research due to the significant consumption of natural resources demanded by concrete.

Recent research has focused primarily on the utilization of steel fibers and rubber particles from scrap tires as recycled gravel substitution in concrete mixes [7]. Extensive investigations have been conducted on the incorporation of rubber recycled gravel in multiple cement-based materials including conventional concrete [4, 8], roller-compacted concrete [5, 9], treated crumb rubber concrete [10], self-compacted concrete [11-13] and in compaction methods of rubberized concrete [14]. Throughout these studies, it was demonstrated that incorporating rubber in concrete alters its behavior in both its fresh and hardened states. Furthermore, the use of rubber particles in concrete was reported to produce a lighter material, increase the energy absorption potential, and improve ductility. However, the existing literature reveals conflicting results of the effect of rubber particles on the workability of concrete. Youssf et al. [15] reported a reduction of workability in conventional concrete when crumb rubber was used as recycled gravel. In addressing this situation, researchers have reported that the use of shredded rubber tire particles smaller than 8 mm in diameter can improve the workability of rubberized roller compacted concrete [16]. Additional studies [17, 18] have reported that an increase in the content of superplasticizer could mitigate workability reduction of self-compacting concrete containing rubber (RSCC). A study by Jiang and Zhang [19] also indicated that adding rubber, with a maximum size of 4 mm, to SCC did not have any direct effect on its workability if a viscosity agent was added in the mixture. Based on the present literature, there are limited studies that focus on the rheological properties of RSCC.

One of the leading drawbacks of incorporating rubber in concrete is a resulting reduction in compressive and flexural strength which hinders its widespread application. Previous studies have reported that this strength reduction may be attributed to the deformability of rubber and inefficient adherence of the interface between rubber and cement paste in comparison to natural gravel. In an attempt to address the latter, methods such as treating the rubber with sodium hydroxide, altering rubber roughness via mechanical processes, and implementing silica fumes as supplementary cementing material have been investigated [20, 21]. Another property of rubberized ordinary concrete is its low heat conductibility which supports regulating building temperature in moderate climate zones [22–24]. However, limited analysis has been conducted on this feature and additional investigation on the thermal conductibility of RSCC is required.

Another concern of rubberized cement-based material is its ability to incorporate water into the mix which has drawn varied results from multiple independent studies. In one study, the incorporation of rubber was reported to decrease the absorption of water due to the reduction in effective area crossed by water [25]. In contrast, Heshami et al. [26] and Lopes et al. [27] have observed an opposing trend which was attributed to an improved porosity in SCC mixes caused by variations in the shapes and sizes of rubber particles. Furthermore, durability-related properties such as chloride ion penetration of rubberized SCC are not well addressed and require further evaluation. When incorporating rubber into ordinary concrete at volume contents of less than 7.5%, the diffusion of chloride ions was evidently reduced [25]. A similar response was reported for rubber incorporation in SCC as well [28]. For larger rubber particle sizes, Bravo and De Brito [29] reported an alternative behavior in which chloride ion permeability of concrete was found to increase.

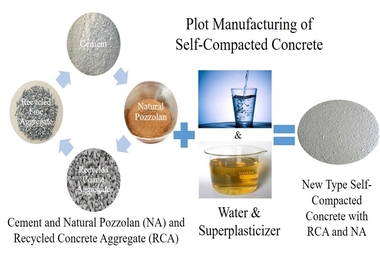

The present study conducts an experimental investigation of SCC incorporating recycled tire rubber as fine gravel towards an environmentally sustainable and natural resource conserving alternative. The specimens accounted for five variations of rubber content which partially substituted natural sand as fine gravel at rates of 0, 5, 10, 15, 20 and 30% volume. The objective of the conducted analyses is to address the limited knowledge on pertinent parameters of workability, water absorption, thermal conductivity, and penetration of water and chloride ion, as defined by the literature. In addition to these, the current work thoroughly investigates the rheological, mechanical, and shrinkage properties of rubber incorporated SCC. By expanding on the current state-of-the-art in rubberized SCC properties and behaviors, it both inspires future research and further supports practical application.

2 Materials and methods

2.1 Material and mix details

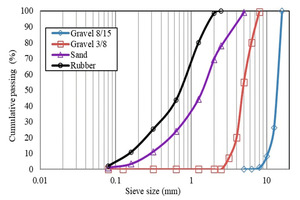

The cement used in each mix variation was type CEM II/B 42.5N with specific surface of Blaine of 464 m2/kg. Table 1 summarizes the chemical and mineralogical compositions of the cement. Two classes of crushed limestone gravels (3/8 and 8/15) having a dry unit weight of 2.53 kg/m3 and water adsorption of 1% were used. Furthermore, dune sand was used having a maximum diameter of 5 mm, fineness modulus of 2.56, density of 2.61 kg/m3, and a water adsorption of 1.34%. The superplasticizer (SP) used in the mixes was polycarboxylate based (Medaflow 30) with a specific density of 1.06 kg/m3. Additionally, graphite nano particle with percent of cement mass among 0.01 and 0.03 and rubberized fine gravels with a maximum diameter of 2 mm, density of 0.77 kg/m3 and water absorption coefficient of 0.24 were used throughout experimental investigation. It is also noted that the recycled rubber fine gravel was supplied by a local factory through the mechanical shredding of used tires as shown in Figure 1. Moreover, grading analysis curves for the distribution of both natural fine gravel and rubberized recycled fine gravel are also illustrated in Figure 2.

2.2 Methods of experimental testing

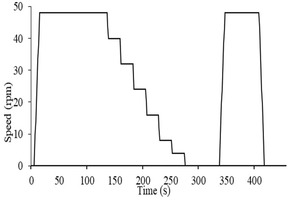

At its fresh state, density, air content, and workability tests were performed on SCC mixes according to the specifications of the European guidelines [30]. Slump flow tests were also conducted and consisted of measuring the perpendicular diameters of SCC at its fresh state. This allows for the quantification of its flow capability in surfaces without obstacles. Moreover, common parameters to evaluate the flow capability of concrete in complex formwork and extremely congested reinforcement bars are the T500 duration, V-funnel duration, and L-box ratio. To evaluate the rheological characteristics (plastic viscosity and yield stress) of SCC mixes, a computer-controlled rheometer is used as illustrated in Figure 3a. The time and speed of the rheometer are also adjusted based on the concrete profile shown in Figure 3b [31].

The mechanical properties of compressive strength and flexural moment at the hardened state were evaluated in conformity to ASTM C39 and ASTM C78 [6, 31]. Cubic and prismatic specimens of dimensions 100×100×100 mm3 and 280×70×70 mm3 were cast for both compressive and three-point flexural tests, respectively. After 24 hours, the specimens were demolded and cured in water at a temperature of 20 °C. When reporting on the mechanical properties, the arithmetic mean of three values was considered for all SCC mixes.

The total shrinkage deformation was measured according to ASTM C878 using prismatic specimens of dimensions (70×70×280) mm3 [31]. The first measurement was taken after demolding at 24 hours and conservation of the specimens in the laboratory conditions (55% RH and 20 °C) and measurements were done regularly up to 28 days.

The thermal conductibility was determined for each rubber content of SCC mix in accordance with NF EN 993-15 standards [6, 31] based on 100×100×100 mm3 cubic specimens after being cured in water at a temperature of 20 ± 2 °C for 28 days and oven dried at 50 ± 2 °C.

The properties of water absorption through capillarity, permeability of water under pressure, and rapid chloride permeability tests were carried out in conformity to ASTM C1585, DIN 1048 and ASTM C1202 standards, respectively [7,31]. Cubic specimens, having dimensions of 100×100×100 and 150×150×150 mm3, and cylinder specimens, having a diameter of 100 mm and height of 50 mm, were used for capillary water absorption and permeability of water and chloride-ion, respectively. All specimens were dried in an oven at a temperature of 50 ± 2 °C for 180 days after being cured in water.

A preliminary testing was conducted in order to optimize the dosage of SP towards obtaining a concrete mix that was homogenous, sufficiently stable, and eliminated segregation risk. The preliminary study was carried out using the general method of Okamura [32, 33]. For all mixes, the sand-to-mortar ratio, water-to-cement ratio, and dosage of SP remained constant in which the only variable parameter was the rubber content. The mix constitu-ents for one cubic meter contained cement, gravel (size 3/8), gravel (size 8/15), sand, SP, and water at mass values of 442.4, 465.26, 347.69, 819.7, 4.42, and 200.7 kg, respectively. Moreover, the rubber was added to the mix in percentages of 0, 5, 10, 15, 20 and 30% by volumetric substitution of sand and graphite nano particle was inserted into the mix in percentage of 0.01, 0.02, and 0.03 mass of cement.

3 Results and discussion

The current section presents the results pertaining to the density and air voids, workability, segregation, rheological properties, mechanical properties, thermal conductibility, shrinkage, water absorption, and penetration behavior for water and chloride ions of the tested specimens. For each property, the effect of varying rubber content was quantified and comparisons to related studies were also made to corroborate results.

3.1 Density and air voids

Upon uniformly mixing the constituents, the density and air contents were measured according to NF EN 12350-6 and NF EN 12350-7 standards, respectively [6, 7, 31] with the results presented in Figure 4. It can be observed that an increase in rubber content resulted in a reduction of density. A 0.43 kg/m3 change in density was observed between the RSCC0 and RSCC30 mixes having densities of 2.41 kg/m3 and 1.98 kg/m3, respectively. This reduction in density may be explained by the low unit weight of rubber in comparison with the partially replaced natural fine gravels. These results are further supported by earlier studies which also noted a decrease in the density of rubberized cement-based materials [29, 34-37].

Figure 4 also illustrates the relationship between the rubber content and the air content. It can be noted that the percentage of air voids increases with an increase in rubber content in SCC mixes. The air voids varied from 2.3% to 4.3% for SCC mixes containing 0% to 30% rubber content, respectively. The increase in air content is most likely due to the roughness and the irregularity of rubber particles in concrete which trap a greater volume of air compared to natural gravels. These findings are also found to agree with those of Gillani et al. [38]. In their study, they considered a constant water-to-binder ratio of 0.4 and an air-entraining agent of 0.46 kg/m3 such that the phenomena of segregation was found to decrease. The results further indicated an increase in air content of 8.7% when 25% rubber content, with particles of 4 to 10 mm in size, was incorporated in SCC and hence the loss of density.

3.2 Workability

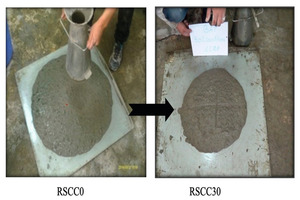

The fluidity and the flowability, without any obstacle of the SCC mixes, were achieved via by slump flow tests displayed in Figure 5. The material’s capacity to flow in dense reinforcement areas was measured with an H2/H1 blocking ratio in the L-Box test. Table 2 presents the variation of slump flow and blocking ratio considering varying rubber contents. Based on these tests, it was observed that the addition of rubber significantly affected the fluidity of SCC mixes. The slump flow decreased from 760 mm to 520 mm, whereas the H2/H1 ratio ranged between 98% and 53% for the SCC mixes containing 0% and 30% of rubber content, respectively. The obtained results show that all SCC mixes, except RCC30 mix, satisfied the condition of the slump flow test according to [30]. However, RCC20 and RCC30 mixes present blocking ratio values lower than the required ratio being 80%. These results confirm the findings of earlier studies [26, 39]. In a study by Wang et al. [40], it was reported that utilizing 15% rubber content with a maximum particle size of 2.83 mm as a sand replacement decreased the flowability of SCC. However, an improvement to workability was noticed with 15% rubber treated with NaOH. Comparable results were also reported by Khalil et al. [39] in which rubber, having particle sizes between 2 mm to 4 mm, was used as a sand substitute in SCC and found that the slump flow had reduced by 11.5% with an observed reduction of 13.8% in the material’s ability to pass through obstacles. Hesami et al. [26] also noted decreases of slump flow and L-box ratio from 745 to 700 mm and 0.88 to 0.76, respectively. They attributed the decreases in flow to a reduction of water-to-cement ratio and to the shape of tire rubber crumb with a size of 4.75 mm having sharp edges and irregular shapes. The same argument stated by Aslani et al. [41] during their investigation into the influence of rubber at different particle sizes (2 mm, 5 mm, and 10 mm) on fresh and hardened properties of SCC having a constant water/binder ratio of 0.45. For all particle sizes considered, they attributed the negative effect of rubber on the workability of SCC to the particle shapes and jagged edges. Based on the present results, as well as previous reports, a limit of 15% rubber content as a sand substitute is recommended to ensure both workability and flowability on surfaces with and without obstacles. It is also noted that the reduction of fluidity caused by incorporating rubber could be compensated by increasing the SP content in the mix which allows for a higher substitution rate [17].

The filling ability of the mixes was also evaluated via V-Funnel and T50 tests according to the European Guide [30]. The variation of V-funnel flow duration and T500 duration based on rubber content are also presented in Table 2. When incorporating 30% of rubber content, the V-funnel duration increased from 2.2 s to 8.3 s, whereas the T500 duration increased from 0.22 s to 0.73 s. This behavior further corroborates the results mentioned above, where rubber content leads to a decrease in the workability of SCC. Furthermore, the decrease of the fluidity and the increase in the viscosity of concrete might be attributed to the friction mobilized between the rubber, paste, and natural aggregates. This argument is also consistent with a previous outcome of using coarse rubber gravel sizes of 4 mm or greater [17, 26]. Moreover, the use of mineral additions, such as fly ash, was found to increase the workability of rubberized SCC [42] while utilizing rubber particles treated with NaOH was also reported to improve workability [40].

3.3 Segregation stability

The resistance to segregation was evaluated through the stability test. Table 2 presents the variation of the rate of segregation based on rubber content. The percentage of resistance varied from 5.87% to 3.4%, when rubber particles were incorporated at a rate of 30%. This demonstrates the positive influence of rubber incorporation in SCC towards reducing the risk of segregation. The cause of this improvement may be attributed to rubber particles adhering better to the cement paste compared to natural gravels. In addition, the “apparent cohesion” observed during the slump flow test could be responsible for this behavior as well. A study by Thakare et al. [43] reported similar results in which a column segregation test was conducted on SCC with rubber shreds of 25 mm, 50 mm, and 75 mm in length. They indicated that the increase in fiber length decreased column segregation resistance, whereas a greater fiber percentage acted to improve segregation resistance. Alternatively, the study by Turatsinze and Garros [44] reported an opposite correlation than the present study and [43]. It is also noted that an increase in the rate of segregation was reported when an air-entraining agent was used [44].

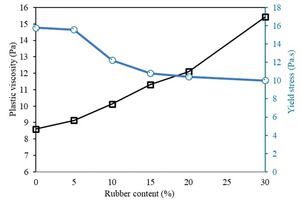

3.4 Rheological parameters

The rheological behavior was studied using a rheometer in which the results are presented in Figure 6. In this case, the relevant measurement are the yield stress and plastic viscosity which are two main rheological parameters. Based on the trend in Figure 6, an increase in rubber content resulted in a regular increase in plastic viscosity in which the increase in viscosity ranged from 8.61 Pa to 15.43 Pa, when incorporating 30% of rubber. Alternatively, the yield stress was shown to decrease for the same rubber content from 15.78 Pa.s to 10 Pa.s. It can be inferred that the presence of rubber particles increases the friction between the mix components, hence resulting in a less fluid and more viscous mix. In addition, the results obtained by the rheometer test corroborated the results observed in classic tests.

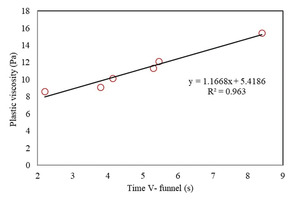

Based on the correlation plots in Figures 7 and 8, excellent correlations between plastic viscosity and slump flow (Figure 7) and plastic viscosity and V-funnel flow time (Figure 8) are found with favorable values of R2. These equations enable the estimation of plastic viscosity of rubberized SCC from fresh properties, like slump and time flow V-funnel. This provides a convenient and accurate means for researchers to estimate the plastic viscosity of SCC including waste rubber recycled gravel as well. It should be noted that in the present experimental investigation, a simpler linear regression between plastic viscosity and slump and time flow V-funnel is proposed as opposed to the polynomial and exponential equations proposed by several previous works.

3.5 Mechanical properties

The 28 days compressive and flexural strength results are shown in Table 3. It can be clearly noted that the incorporation of rubber in SCC reduced both compressive and flexural strengths. The decrease in compressive strength decreased significantly from 48.2 MPa to 23.5 MPa when incorporating rubber at a substitution rate of 30%, while a corresponding decrease of 5.4 MPa to 2.1 MPa was observed for flexural strength, except the RSCC5 made of rubber powder and graphite nano particle 0.02 and superplasticizer. These results are expected based on the previously discussed literature and directly correlate with other investigations conducted on rubberized self-compacted concrete [45].

The deformable aspect of rubber in comparison to the natural gravels could be responsible for the decrease in the compressive strength of rubberized concrete. Alternative causes of this undesirable response may include the concentration of stresses around rubber particles in the cement paste, reduction of solid load-carrying material, and low adhesion between rubber particles and cement paste [20, 46, 47-50]. It is also noted that the poor adhesion creates low-strength zones which induces failure beginning with the separation of rubber particles from the cement paste which, in turn, causes stress concentrations in neighboring areas.

3.6 Thermal conductibility

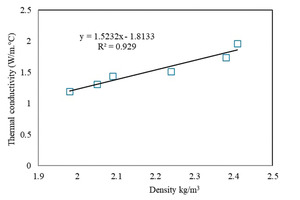

The potential to transfer energy through rubberized SCC was evaluated by the thermal conductibility tests as shown in Figure 9. It can be observed that rubber significantly reduces the thermal conductibility of SCC. The quantity of this parameter for the RSCC30 mix decreased by 39.3% when compared with RSCC0. The results obtained are also supported by those reported in the literature [51]. Furthermore, Marie [52] reported that for rubber, with particles sizes ranging from 0.075 to 4.75 mm, an increase in rubber content from 0% to 20% reduces the thermal conductibility of concrete from 1.25 to 0.9 w/m.K, respectively. A decrease of 60% in the thermal conductibility was also observed when cement was replaced with 50% by volume of rubber with particle sizes less than 1 mm [53]. A highly acceptable correlation between the thermal conductibility of rubberized SCC and its density is also presented in Figure 10. Overall, the lower thermal conductibility of rubber as compared to that of natural sand as well as the increase in entrapped air result in a lower thermal conductibility of rubberized concrete composite. In addition, the roughness of rubber surfaces leads to the creation of closed porosity zones which further improves the insulation property of the final product [52, 53].

3.7 Total shrinkage

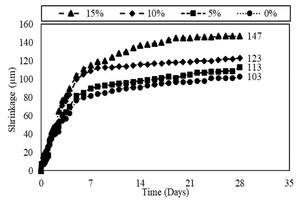

The total shrinkage behavior of SCC with rubber content is depicted in Figure 11. From these curves, an increase in recycled rubber content can be shown to produce a greater total shrinkage value. The increase in total shrinkage might be associated with a lower elastic modulus and deformable nature of rubber in comparison to the more rigid and less deformable natural gravel. Moreover, it can be noted that the total shrinkage develops more quickly for mixes with any quantity of rubber particles in comparison with the reference mixture. A change of nearly 30% in the specimen’s shrinkage length was observed considering 15% rubber content in SCC. The outcomes presented in this section are also consistent with results reported from multiple other studies [54-58]. It was also reported by Gravina and Xie [54] that the increase in shrinkage was due to the open porosity caused by an increase of water-to-powder ratios from 0.4 to 0.51 and by the entrapment of air caused by the rubber considering self-consolidating mortars containing 4.75 mm sized rubber particles.

3.8 Capillary water absorption

The variation of the rate of water absorption by capillary action with rubber content was also investigated. It consisted of evaluating the quantity of water absorbed by the rubberized SCC specimens per area unit, in relation to time. The results are presented in Figure 12 which demonstrates that the partial substitution of sand by rubber causes a considerable decrease in the water absorption capacity of SCC mixes. This behavior may be attributed to the lower water absorption of rubber in comparison to that of natural gravels and to the closed porous zones created by the rubberized cement-based materials [59]. Meddah et al. [60] reported similar behaviors and explained that the reduction is due to less effective area accessed by water.

However, an opposite behavior was reported by other researchers [26, 47, 54]. They suggested that the irregular shape of the rubber particles, which amplifies the volume of entrapped air, increased porosity. Considering the variability of results reported on the capillarity absorption of rubberized cement-based materials from both the literature and current study, a dedicated investigation should be conducted to precisely identify the parameters affecting this property.

3.9 Water penetration and ion chloride penetration

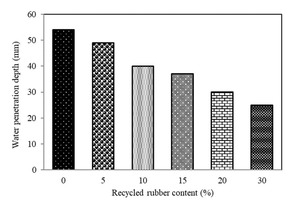

The ability of concrete to resist external aggressive agents is mainly characterized by the permeability test. Figure 13 presents the variation of water penetration of rubberized SCC based on rubber content while Figure 14 shows the variation of chloride ion penetration. The water permeability, as measured by the water penetration depth, was found to decrease with an increase in rubber content. Water penetration depth deceased by 53.7% when 30% rubber content was used. Similarities are observed between these results and the capillary absorption test results while also being comparable to experimental findings from alternative studies [54, 61]. The reduction in water permeability is beneficial as it enhances the durability performance of rubberized SCC concrete which strongly supports its application under more aggressive environments.

Unlike the water permeability test, penetration tests of chloride ions display an opposite trend where the inclusion of rubber acts to increase the penetration of chloride ions. As shown in Figure 14, The change in charge passed from 2230 to 4310 Coulombs which indicate a change from moderate to high permeability according to ASTM C 1202-94 [6, 7, 31]. Similar results have been reported in the literature [29, 61, 62]. The higher chloride penetration could also be attributed to the probable reaction between the rubber particles and NaOH solution during the test which could have created more voids and consequently increase chloride penetration. Based on these tests, it is noted that the increase in chloride ion penetration could limit the use of rubberized SCC in applications with high risk of chloride attack.

4 Conclusion

The present paper experimentally investigates the potential use of recycled rubber salvaged from scrapped tires as fine gravels in SCC. Natural fine aggregates were partially replaced with recycled rubber waste in volume contents of 0, 5, 10, 15, 20, and 30%. Extensive experimental examination was conducted on properties of density and air voids, workability, segregation, rheological properties, mechanical properties, thermal conductibility, shrinkage, water absorption, and penetration behavior of water and chloride ions. The various results demonstrated that the partial substitution of natural sand with recycled rubber affects these fresh and hardened properties of SCC where the primary conclusions drawn from this study are as follows:

Incorporating rubber in SCC increased the air content of the mix due to air entrapment on the rubber surfaces. In addition to this, rubber material possessed a lower unit weight in comparison with natural gravels. These two parameters promoted a lighter material which is advantageous for concrete structures.

Through concrete workability testing, it was found that the substitution of fine natural aggregates by rubber reduces its potential to flow in surfaces without obstacles as well as with denser reinforcement. However, a 15% limiting rubber content satisfied the workability requirement of European guidelines.

An increase of rubber content in SCC was observed to produce a higher viscosity and lower yield stress resulting from increased friction between mix constituents thereby affecting the fluidity of the mix.

The incorporation of rubber in SCC significantly improved the thermal conductibility, reduced the water capillary absorption, and water penetration of SCC mixes, which enhances durability of rubberized SCC-based structures and could contribute to insulation in hot climate conditions.

The behavior of both mechanical properties and total shrinkage were negatively affected by the presence of rubber in SCC mixes which may be explained by the low stiffness of rubber and the reduction of solid-carrying fine gravel, except the RSCC5 made of rubber powder and graphite nano particle 0.02 and superplasticizer. The best sample with compressive strength of 48.23 and flexural strength of 5.41 is the RSCC5 in the experimental and scientific work.

The substitution of sand with rubber for all content values was found to increase the penetration of chloride ions which limits its application in high-risk chloride zones.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.