Effect of nano-TiO2 on chloride ingress in cementitious material

The influence of nano-TiO2 (NT) on impermeability to chloride ions of mortars was studied by the rapid chloride migration (RCM) method, and the improvement mechanism was analyzed by X-ray diffraction (XRD), differential scanning calorimetry-thermogravimetry (DSC-TG), scanning electron microscopy (SEM) and mercury intrusion porosimetry (MIP). Results show that the addition of NT helps strengthen the chloride resistance of mortars. Dosages of 1 %, 2 % and 3 % reduce the chloride diffusion coefficient by 6.6 %, 19.4 % and 31.1 %, respectively. It is concluded from mechanism analysis that the micro-aggregate filling effect and the heterogeneous nucleation effect promoting the generation of hydration products of NT, together affect the pore structure and compactness of mortars, further improving their ability to counter chloride diffusion.

1 Introduction

Severe durability problems caused by chloride ingress into concrete in a marine environment, such as reinforcement corrosion, cracking and peeling, performance degradation and decrease of service life, have attracted widespread research attention. External chloride ions migrate into concrete primarily through pores within cementitious materials, so it is obvious that the anti-chloride ion permeability of concrete is closely related to its pore structure. Research by Anders et al. [1] found that the capillary porosity of cement paste increased along with the water-cement ratio....

1 Introduction

Severe durability problems caused by chloride ingress into concrete in a marine environment, such as reinforcement corrosion, cracking and peeling, performance degradation and decrease of service life, have attracted widespread research attention. External chloride ions migrate into concrete primarily through pores within cementitious materials, so it is obvious that the anti-chloride ion permeability of concrete is closely related to its pore structure. Research by Anders et al. [1] found that the capillary porosity of cement paste increased along with the water-cement ratio. Duan et al. [2] studied the resistance to chloride ion penetration and pore structure of concrete with low water-binder ratio under various curing conditions and discovered that, at negative and low curing temperatures, the proportion of harmful and very harmful pores in cement paste increased markedly compared to that observed under standard curing conditions, so the ability to counter chloride diffusion was accordingly low. Recently, a series of measures, including mineral admixture [3, 4], high efficiency water reducing agent [5, 6] and polymer modification [7-9], were taken to increase the compactness and improve the pore characteristics of cementitious materials, further improving their ability to counter chloride diffusion and increasing the durability of the concrete structure. However, these measures sacrifice other performance aspects of cement-based material, hence limiting their widespread application.

As a new functional material, titanium dioxide (TiO2) has been widely used in cementitious composites thanks to a variety of distinctive advantages such as air pollution remediation [10, 11], self-cleaning [12, 13] and bactericidal performance [14-16]. As for nano-sized TiO2 (NT), it offers not only the same advantages as ordinary TiO2, but also the micro-aggregate filling effect needed to increase the compactness of the cement matrix and promote cement hydration due to the heterogeneous nucleation effect caused by its superfine particles. It is therefore necessary to study the use of NT in cement-based material. Chen et al. [17], who have systematically discussed the effects of NT on the physical and hydration characteristics of cementitious composites, found that NT could improve early hydration of cement. Ma et al. [18] found that NT might accelerate the formation and precipitation of hydration products and improve the interfacial transition zone structure of the cement matrix. To date, although photo-catalytic nano-TiO2 as an admixture of special functional concrete had been extensively studied, little research has been performed regarding the effects of NT on the inherent performance of hardened cement paste, especially its durability.

In this paper, the chloride penetration resistance of NT–modified mortars is studied, and the mechanisms by which addition of NT may delay corrosion initiation and control corrosion propagation in chloride-containing environments are investigated and discussed.

2 Raw materials and experimental program

2.1 Raw material

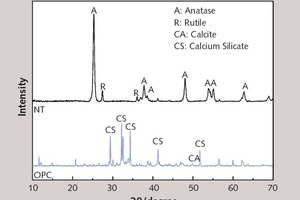

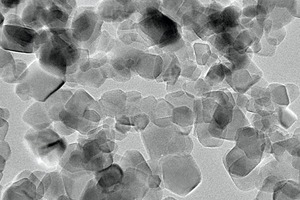

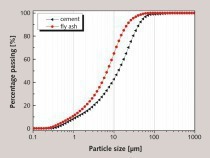

Ordinary Portland cement (OPC) CEM I 42.5 produced by Huaxin Cement Co. Ltd with a specific gravity of 3.13 and a surface area of 350 m²/kg was used. Nano-TiO2 (NT) with an average particle size of 21 nm was purchased from the Degussa Company. The chemical composition of the cement is shown in Table 1. XRD patterns of OPC and NT are shown in Figure 1. A transmission electron microscopy (TEM) image of NT is given in Figure 2. China ISO Standard Sands (SS) were used as aggregate, the silicon content was above 96 %, and the ignition loss was below 0.4 %.

2.2 Mix proportion and sample preparation

Cement mortars were mixed at a sand-binder ratio of 3 and a water-binder ratio of 0.5. Different dosages of NT (1, 2, 3 wt.% of binders) were added to the mixes. Liquefied SDS (sodium dodecyl sulfate)-type polycarboxylate superplasticizer was used to ensure that the different mortars would have the same fluidity. Before the mortars’ preparation, NT was added to deionized water, stirred and dispersed with an ultrasound device at 325 W for 30 min to obtain uniform suspensions. Their detailed mix proportions are listed in Table 2. For SEM and MIP examination, samples of small fragments were obtained from the middle part of the mortars at 28 days. These were shaped in a mould measuring 40 x 40 x 160 mm and stored in acetone solution for 3 days. Samples were then dried at 40 °C for 24 h. For chloride diffusion coefficient testing, the specimens were molded in cylindrical molds with a diameter of 100 mm and a height of 50 mm.

As for XRD and DSC-TG testing, the cement specimens were molded in steel molds with a size of 40 x 40 x 40 mm. The proportions of cement pastes are also given in Table 2. After curing for 28 days, hydration of the pastes was stopped by submerging the centre part of the crushed specimen in acetone solution, drying it at 40 °C for 24 h in an oven and, finally, powdering them in an agate mortar so as to pass the 100 mesh size sieve.

Rapid methods for determination of chloride resistance of cement-based materials mainly include rapid chloride permeability (RCP) testing, accelerated chloride migration (ACM) testing and rapid chloride migration (RCM) testing. However, the poor accuracy and other drawbacks of RCP testing [19], plus poor correlation with other unsteady state diffusion coefficients of ACM testing [20, 21], limit their range of application. The RCM method not only can reflect the actual situation of chloride ion transport process, but also involves less interference factors due to its constant test temperature, and, most importantly, it shows better correlation with other unsteady state diffusion coefficients. It therefore can be concluded that the RCM test method presently offers comparatively high reliability for a laboratory approach to determining the penetration of chlorine ions. In this paper, RCM testing was performed according to GB/T 50082-2009 [22] using an RCM-DAL chloride ion diffusion coefficient tester. The relevant schematic is shown in Figure 3. The anode bath is a 0.3 mol/l NaOH solution of 300 ml, and the cathode bath is a 10 % (mass fraction) NaCl solution of 12 l. The time-dependent penetration depth can be measured by spraying the 0.1 mol/l AgNO3 solution as color indicator on the split concrete surface, and the chloride ion diffusion coefficient (DRCM) can be calculated using the following formula [23-25]:

DRCM = 2.872 x 10-6 Th (Xd-α √Xd)⇥(1)

t

α = 3.338 x 10-3 √Th⇥(2)

Where T, h, Xd, t and α represent the average values of the initial and final temperatures of the anode solution, the height of the specimen, the chloride diffusion depth, the electrolytic time and the instrumental variable, respectively.

The phase structure and composition of samples were observed by XRD with a Cu kα X-ray source at 40 kV and 40 mA, and the data were collected with a step-length of 0.02 ° and a scanning rate of 2°/min, while 2θ ranged from 5 to 60°.

The paste sample was thermally analyzed by DSC-TG at a heating rate of 15 °C/min from 20 °C to 800 °C in an atmosphere of nitrogen.

The microstructure of hardened mortars was examined by means of SEM with about 10 mm working distance in low vacuum mode.

The pore structure of mortars was studied by MIP with the measurable aperture ranging from 5 nm to 200 μm, a maximum pressure of 300 MPa and a contact angle of 140°.

3 Result and discussion

3.1 Chloride diffusion coefficient

Figure 4 shows the effect of NT on the chloride diffusion coefficient of mortar specimens.

As can be seen from the bar graph, the DRCM of the specimen without NT, being the highest in all samples, was 1.96 x 10-11 m2/s. However, the addition of NT obviously lowered the DRCM of the concrete. To be specific, the DRCM of the specimen with 1 %, 2 % and 3 % NT were 1.83 x 10-11 m2/s, 1.58 x 10-11 m2/s and 1.35 x 10-11 m2/s, respectively, being 6.6 %, 19.4 % and 31.1 % lower than that of control specimen. Clearly, NT-modified mortar had much stronger chloride penetration resistance. This enhancement mechanism caused by NT is investigated and explained via XRD, SEM, DSC-TG and theoretical analysis below.

3.2 XRD analysis

The influence of NT on the chloride-permeation resistance of mortars can be identified by the change of microstructure and hydration products. Figure 5 shows the XRD patterns of NT modified cement pastes at 28 days.

Apparently, the CH diffraction intensity decreased with an increasing content of NT, and the C3 S and C2 S peaks showed similar patterns, a fact which was closely related to the heterogeneous nuclei effect of NT. To be more specific, the hydration of cement was able to be accelerated because superfine NT particles provided many heterogeneous nucleation sites for hydration products, leading to the consumption of CH. Accordingly, the quantity of C-S-H increased. All of this promoted the depletion of clinker and lowered the content of C3S and C2S. The increase in hydration products made the paste more compact, effectively blocking chloride diffusion and infiltration into the mortars and improving the mortars’ resistance to chloride ion permeability, which was in good agreement with the results shown in Figure 4.

3.3 DSC-TG analysis

DSC-TG curves of pastes with different NT content are shown in Figure 6. As can be seen from that figure, there were two main endothermic valleys in every DSC curve. The first one was related to the loss of bound water of C-S-H, occurring within the temperature range from 50 to 300 °C. The second one was related to the decomposition of CH, occurring within the temperature range from 400 to 500 °C. Clearly, the C-S-H valley deepened as the NT content increased, which indicated that NT with high heterogeneous nucleation effect was beneficial to the hydration of cement to generate C-S-H gel. Accordingly, the TG curves showed 7.75 % weightlessness in the sample without NT, 8.36 % in the sample with 1 % NT, 9.57 % in the sample with 2 % NT and 10.65 % in the sample with 3 % NT. Therefore, it can be concluded that the information concerning the major hydration product C-S-H, which was not directly provided by XRD, can be reflected intuitively by DSC-TG curves, and that the C-S-H tended to increase with an increasing NT level. An increase in C-S-H gels led to an increase in compactness of matrix, further resulting in higher resistance to chloride corrosion.

However, the influence of NT on the CH valley displayed a totally different trend compared to that of C-S-H, and, more concretely, the depth of the CH valley decreased with an increasing NT ratio. This was largely attributed to their heterogeneous nucleation effect, which consumes abundant CH in the process of forming C-S-H gel. From the TG curves, it can be observed that the weight losses of CH decomposition were 4.58 %, 3.96 %, 3.21 % and 2.72 %, respectively, in pastes with 0 %, 1%, 2 % and 3 % NT, and that the CH amount can be calculated by the following formula [26]:

CH (%) = WLCH (%) x MWCH⇥(3)

MWH

Where WLCH represents the thermal weightlessness in percent due to the dehydration of CH; MWCH and MWH are the molecular weights of CH and water, respectively.

Figure 7 shows the influence of NT on CH content in pastes. As shown in that figure, the content of CH in samples with 1 %, 2 % and 3 % NT were 16.28 %, 13.20 % and 11.19 %, respectively, or 13.59 %, 29.94 % and 40.61 % lower compared to that found in the sample without NT (18.84 %). This is chiefly because superfine particles of NT can serve as potential nucleation sites for the accumulation of hydration products that trigger extensive CH consumption. These results are consistent with the law demonstrated by XRD.

3.4 SEM analysis

The results of SEM testing for the pure mortar sample and the 1 %, 2 % and 3 % NT-blended samples at 28 days are shown in Figure 8. The SEM analysis revealed that, for the sample without NT, the structure of the hydration products was relatively loose. There were also some unhydrated cement particles and ettringite (AFt) as well as many CH crystals in large-scale and directional arrangement that appeared in the hole, all of which decreased the compactness of the mortars, further reducing their ability to counter chloride diffusion. For sample with 1 % NT, the content of CH decreased and the structure of the hydration phases became denser compared to the control sample. When NT increased to 2 % and 3 %, a number of gelatinous hydrates were generated, and no obvious CH crystals were found. More specifically, the gelatinous hydration products were distributed neither independently nor dispersedly, but showed an integrative structure, which made the paste more uniform and compact, thus improving the chloride penetration resistance of the mortars. In addition, no AFt crystals were found in samples with 2 % and 3 % NT. This may be because the AFt in these samples were so small that they were covered by C-S-H gels.

3.5 Porosity and pore size distribution

As one of the important characteristics of cement mortar, pore structure is the fundamental factor affecting its permeability and chloride resistance. The results of porosity and total pore volume for the pure mortar sample and the 1 %, 2 % and 3 % NT-blended samples at 28 days are shown in Table 3.

Generally speaking, the greater the porosity of a given mortar, the worse its permeability. Table 3 shows that, compared with the control sample, when NT contents were 1 %, 2 % and 3 %, the matrix porosities were lower by 11.25 %, 32.42 % and 50.53 %, respectively. The changing trend of pore volume showed similar characteristics. The reasons that cause loss of porosity and pore volume have two aspects: one is the micro-aggregate filling effect of NT, and the other is the increasing amount of hydration products resulting from the heterogeneous nucleation effect of superfine particles, all of which would increase the compactness of mortars, further enhancing their ability to counter chloride diffusion.

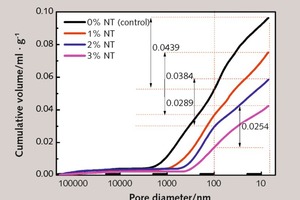

The performance of cement-based material is not only related to porosity, but also closely associated with the pore size distribution, which is another important factor that affects the physical and mechanical properties and the durable performance of cementitious composites. Figure 9 shows the integral curves of pore size distribution of TiO2-blended cement mortars hydrated at 28 days. Of all kinds of pores, the capillary pore with diameter size ranging from 5 to 100 nm has the most unfavorable influence on chloride diffusivity in mortars. In such pores, not only was the phenomenon of capillary condensation observed [27] to be increasing the hygroscopicity of pores, but also higher capillary pressure and osmotic force were created, thus increasing the autogenous shrinkage of mortars [28] and simultaneously accelerating both the surface infiltration rate and the atmospheric infiltration rate, which would yield an overall reduction in surface and atmospheric penetration resistance. As Figure 9 shows, the volume of capillary pores (5~100 nm) in the control sample was 0.0439 ml · g-1, while the addition of 1 %, 2 % and 3 % NT made the volume of these kinds of pores decrease by 12.5 %, 34.2 % and 42.1 %, respectively. This shows that, to some extent, NT has filling and compacting functions for mortars that can improve the pore size distribution, hence also dramatically improving the chloride penetration resistance of cement-based materials. All of the above results were exactly consistent with RCM analysis.

4 Conclusion

This paper emphatically discussed the influence of nano-TiO2 on chloride permeability of mortars and its mechanism. The main conclusions were as follows:

The addition of NT significantly improved the impermeability to chloride ion of mortars, and within the scope of this test, the optimal mixing quantity of NT is 3 %

The amount of C-S-H increased along with the content of NT, while CH displayed a totally different trend. Some unhydrated cement particles and AFt, as well as many large-scale and directional arrangements of CH crystals were present in pure cement mortar, and with increasing NT content, the gelatinous hydration products showed a trend toward integrative structure, while no obvious CH and AFt were found

Dosing NT into cement mortars lowered the porosity and modified both the pore size distribution and the total pore volume. The addition of 1 %, 2 % and 3 % NT made the volume of capillary porosity (5~100 nm) of mortars decrease by 12.5 %, 34.2 % and 42.1 %, respectively

The micro-aggregate filling effect and heterogeneous nucleation effect of NT, together affect the pore structure and compactness of mortars, further improving their ability to counter chloride diffusion

5 Acknowledgement

The authors would like to acknowledge the 13th Five-Year Plan of National Key Research and Development (2016YFC0701003-05) and the Science and Technology Support Program of Hubei Province (2015BAA084).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.