Lime production experience 4.0

Italian plant engineering contractor QualiCal has designed and built a 150 t/d Synthesis regenerative vertical kiln (PFR – twin shaft burning unit) for Köhler Kalk. The kiln boasts rock-bottom investment and running costs and is capable of turning out quicklime of the highest quality. Digitization was one of the project’s major elements.

1 The calcination process

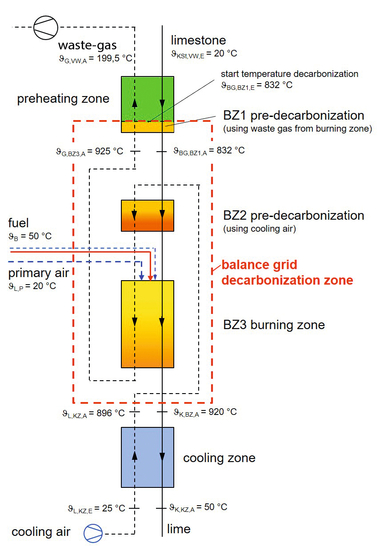

The calcination of limestone is a chemical process of decomposition in which heat applied to carbonates decomposes them into oxides. Decomposition takes place at a temperature of around 810 °C:

CaCO3 + heat = CaO + CO2

To ensure that the limestone rock decomposes all the way through, the heat of dissociation must be able to penetrate to the core. So, for complete calcination, the surface of the stone must be heated to above 900 °C. The surface temperature, however, should not exceed 1100 – 1150 °C, because that would cause sintering, or dead burning, of the calcined...

1 The calcination process

The calcination of limestone is a chemical process of decomposition in which heat applied to carbonates decomposes them into oxides. Decomposition takes place at a temperature of around 810 °C:

CaCO3 + heat = CaO + CO2

To ensure that the limestone rock decomposes all the way through, the heat of dissociation must be able to penetrate to the core. So, for complete calcination, the surface of the stone must be heated to above 900 °C. The surface temperature, however, should not exceed 1100 – 1150 °C, because that would cause sintering, or dead burning, of the calcined product.

The Synthesis parallel flow heating system ideally provides optimal heating condition. At the beginning of the calcining zone, when the raw material is capable of absorbing a large amount of heat, the kiln ensures a maximum differential between the temperature of the hot gases and that of the raw material. For that purpose, the burner lances extend uniformly into the stone bed.

Then, near the end of the calcining zone, where the two shafts of the kiln are interconnected by a straight channel, the difference in temperature is minimal, hence preventing the lime from dead-burning. The parallel-flow heating system is therefore preconditional for producing soft-burnt lime in a vertical kiln.

Additionally, Synthesis kilns achieve their excellent thermodynamic characteristics via regenerative preheating of the combustion air. The stones in the preheating zone of the kiln act as a regenerator. They accumulate waste-gas heat in the first shaft while the lime is burning in the other one and then impart it to the combustion air for the next cycle.

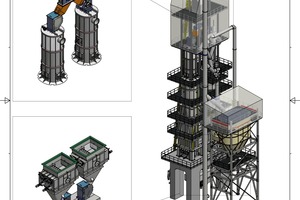

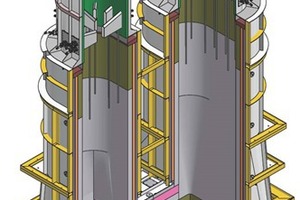

2 Synthesis kiln configuration

The calcination process takes place in a Synthesis lime kiln. The Synthesis kiln differs from the others existing types of twin-shaft kiln by reason of its variform shaft profiles, i.e., the preheating and burning zones are round, while the cooling zone has a rectangular cross section:

Due mainly to the symmetry of its roundness, QualiCal’s original, patent-pending Synthesis solution allows uniform calcination

Beyond that, the straight single-arch channel connecting the two shafts of a Synthesis kiln is a provenly simple, inexpensive, buildup-free solution

Synthesis, with its original design, represents a perfect solution for the vertical lime burning process. The shape of its preheating and burning zones differs from that of the cooling zone.

The transition between the round section (as the best geometry for preheating and burning limestone) and the rectangular section (provenly successful for the cooling of lime in hundreds of kilns now in operation) is smooth and gradual.

The single-width arch subdues turbulence in the flow of gas between the two shafts.

The straight flow of high-temperature gas caters to stable operating conditions, with no unwanted buildup, and enables reliance on the most inexpensive type of refractory lining.

The originality of the kiln’s design maximizes the efficiency of the regenerating burning process in a synthesis of effective solution concepts, some of which have already been adopted in other kinds of operational kilns.

The Synthesis’ excellent thermal characteristics are convincingly demonstrated by its good heat balance. The overall heat loss (as the sum of the sensible heat of the discharged burnt lime and that of the exhaust gas, plus the wall heat losses) is minimal.

Hence, the total heat consumption of a twin-shaft, parallel-flow, regenerative Synthesis kiln ranges between 830 and 875 kcal/kg burnt lime, as attested to by actual process data. Thus, a Synthesis project keeps the investment and running costs low while providing capacity for the production of high-quality quicklime.

3 Synthesis, the digital kiln

Modern lime plants generates terabytes of data but they are not digital.

Today less than 2 % of data is leveraged at all isolating the plant and leaving the lime business in the dark.

To avoid unplanned downtime plants are forced into a conservative balance between operations and maintenance costing billions and unseen value every year.

But what if they did not have to underperform, what if anomalies were predicted and maintenance was based on needs and not on the calendar and what if you could redefine operations using advanced software to transform the entire lime business?

The digital lime plant powered by Mosaico brings dark data into the light: advanced software analytics and low-cost sensing converge with the Industrial Internet to reveal the hidden power of big data and seamlessly connect your entire lime portfolio.

www.QualiCal.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.