The company is our whole life!

Köhler Kalk, a lime plant founded in 1938 and situated in Germany’s heartland, calcines the niche product dolomitic limestone. Just last year the company commissioned a new parallel-flow regenerative (PFR) shaft kiln from QualiCal. We spoke with Christian Köhler, who joined the company with the launch of planning work for the new building project in 2013 and has been managing the company together with his father Norbert Köhler ever since. For a small enterprise with 18 employees, this € 9 million investment is quite a major achievement.

CHRISTIAN KÖHLER: At the time I joined the company in 2013, we were facing the question of whether to quit or invest. With our old standard shaft kiln, we were up to our limits in terms of environmental standards and quality requirements. We would have had to upgrade the kiln in 2017, anyway, because it was no longer able to satisfy Germany’s air quality control code TA-Luft under normal operating conditions.

Since we had gained approval for opening a new quarry that year, i.e., in 2013, we decided to install a new...

CHRISTIAN KÖHLER: At the time I joined the company in 2013, we were facing the question of whether to quit or invest. With our old standard shaft kiln, we were up to our limits in terms of environmental standards and quality requirements. We would have had to upgrade the kiln in 2017, anyway, because it was no longer able to satisfy Germany’s air quality control code TA-Luft under normal operating conditions.

Since we had gained approval for opening a new quarry that year, i.e., in 2013, we decided to install a new kiln and plunged right into the planning. The first question, of course, was which kind of kiln we wanted. We examined a number of different concepts and eventually decided on a parallel-flow regenerative shaft kiln (PFR) from QualiCal. In the summer of 2015, we applied for approval according to the Federal Emission Control Act (BImSchG), which we were granted in record time by January 2016. We commenced construction that spring, and the system went into operation in May/June 2017. Initially, the old kiln remained in operation in parallel with the new one, but the new kiln soon proved reliable, so the old kiln was able to be decommissioned in July.

CHRISTIAN KÖHLER: For us, as a very small lime plant, installing a new kiln at a total cost of € 9 million was a really big project. It amounted to replacing the core component of the whole plant. We chose QualiCal mainly because, for us, they are the most innovative company in the sector. The fact that QualiCal offers numerous innovative approaches was an important point for us. They don’t just want to sell kilns but to improve the “lime production experience” by providing the best-available technological operations. Since the dolomitic lime we burn has a very broad particle size spectrum, the kiln’s mode of operation and boundary conditions had to be adjusted accordingly.

Being that digitization is an important topic for us, QualiCal offered us a digitization package that we considered convincing in combination with all the kiln’s other technical features. Now, I can use the Mosaico app to query the kiln’s crucial data on my smart phone or tablet and, once more experience has been gathered on the kiln’s operation, evaluate them to recognize any emerging problems. While some people may consider such expedients a mere gimmick, I am convinced that digitization does not stop at the threshold of our rather conservative branch of industry. Consequently, it is important for us to make use of cutting-edge technology in our field.

All in all, QualiCal’s high-level innovativeness and flexibility with regard to their customers’ needs was the decisive factor in our decision.

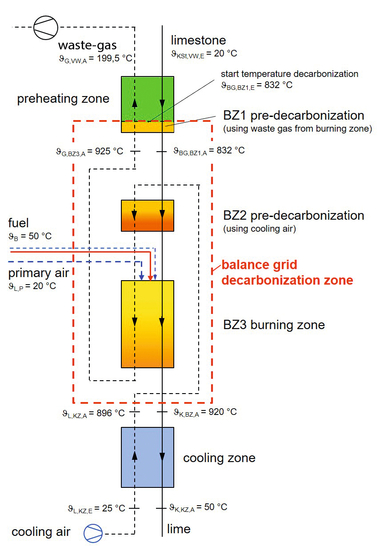

CHRISTIAN KÖHLER: Our PFR kiln is some 50 m high overall, including its 22 m firing zone. It has two shafts connected to each other by a stone spreader at the top and a crossover channel at the bottom. The combustion energy is introduced via 12 lances per shaft. We fuel the kiln with pulverized lignite, which is currently the least expensive source of energy for us. The kiln operates on alternating firing and preheating cycles. The combustion air moves in parallel flow from top to bottom along with the rock charge. The lance burners heat the load, hence “burning” the dolomite at a flame temperature of roughly 1100 °C. Hot air then moves through the firing shaft and over to the other, where it preheats the newly introduced rough rock in a counterflow arrangement. Every 15 minutes, the calcining chamber reverts to the preheating mode, and vice-versa. This gives the PFR kiln a combination of relatively low calcining energy requirement coupled with thermal efficiency. Since the combustion air passes through the hot, non-combusting shaft, it undergoes a form of post combustion. One advantage to this is lower emission levels than for firing in our standard shaft kiln.

On the other hand, it takes more electricity to move the air all the way through the kiln.

CHRISTIAN KÖHLER: The installation process was largely coordinated by Hoffmeier, the company responsible for the steelwork. Hoffmeier really did an excellent job in the quickest possible time. The kiln’s high level of sensor technology is evidenced by the fact that the electrical supply and control scope required some 20 km of cabling. On completion of the installation work, QualiCal helped us with the commissioning and initial configuration.

CHRISTIAN KÖHLER: We doubled our production capacity to 150 t/d, and our calcining energy consumption rate is now situated at approx. 860 kcal/t burnt lime, while our electric power consumption amounts to 40 kWh/t. As already mentioned, our power consumption is now higher than it was with the old standard shaft kiln, so we invested in a 400 kW microturbine CHP to generate our own electricity for the kiln. We are also using waste heat from the microturbine to dry the raw material in an upstream dryer. A positive side effect of this is that it shakes the sand off of the product, hence preventing the rocks from caking together and clogging the bed during the firing process. That is a very interesting point for all those who do not like to use water for cleaning. For us, it is especially important to maintain a low fines fraction in the load of rough rock, since the broad particle size range extending from 25 to 100 mm already gives the kiln a relatively dense packing.

Our experience to date with this system has been very good, and the interest our lime sector colleagues have been showing emphasizes the general importance of this topic. We are open for dialogue with other lime plant operators, and we visited a number of other plants during our own planning stage.

CHRISTIAN KÖHLER: With regard to emissions, our new kiln meets all requirements and reliably complies with the prescribed ceilings. The quality of products from the new kiln is also significantly better.

CHRISTIAN KÖHLER: We always strive to reduce energy expenditures. QualiCal is able to access certain of our kiln data and give us suggestions on further energy optimization from a different point of view. This dialogue will enable us to gradually optimize the new kiln and its energy consumption.

CHRISTIAN KÖHLER: My father has the better overview of our products, inventories and equipment in general. I am more involved in our administration, planning and permits. The new kiln, though, is our intersecting set. For me as a chemist, this presents an excellent opportunity to delve into the technical side of things and gradually become more involved in it. We both contribute all we can to the company, and we work together very closely. I think we complement each other quite well, and just one without the other simply would not work out anymore.

CHRISTIAN KÖHLER: Well, at 57, my father will still be taking an active part for a number of years. I think it is both good and important for the younger generation to run alongside their elders for a while in order to benefit from their experience. At the same time, my affinity for new technologies and digitization is an important factor for my father. Nut-and-bolts experience, of course, is very important, but digital assistance enables lots of things to be replaced step by step. Let me give you just one example: My father, with all his experience, can hear it when a bearing is not running smoothly, while I would notice an increase in power consumption, instead. So, we complement each other in many ways. We discuss things first and then come to a joint decision. This kiln construction project was a great opportunity to get the best out of both generations and start things off with both of us at the same knowledge level.

While € 9 million is a huge investment for a company as small as ours, we would not hesitate to do it again anytime. The company is our whole life, and it is good to handle such a company just as you would a family. Such family enterprises do not focus solely on profits, but on securing the company’s future.

CHRISTIAN KÖHLER: First of all, we want to normalize our operating procedures With the new kiln and at the new quarry. We are presently working to optimize those processes and achieve steady equipment utilization rates. Product development is another goal to be pursued. We also intend to focus more on promoting additional uses for dolomitic lime as a product. There are not very many dolomite deposits left in Germany. It is our conviction that both the raw material and our products are important and deserving of additional promotion. Consequently, we will have to intensify our public relation efforts. As a small-scale lime works, however, we cannot do that all on our own. On that point, we would like to join forces with the lime association and our colleagues.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.