Effect of calcined clays on the

physical-mechanical properties of

hardened Portland cement pastes

Recently, the attention paid by materials scientists to the research, development and application of Portland cements incorporated with calcined clays has substantially increased. This article presents the study results of how clays with different chemical and mineralogical composition calcined at different temperatures influence the properties of Portland cement paste. The results of this study allow us to conclude that it is possible to produce technically and economically effective supplementary cementitious materials for blended Portland cements based on the commonplace polymineral clays with relatively low energy costs on their thermal activation and grinding.

1 Introduction

Seven to eight thousand years ago, calcined clays in the form of flour from ceramic bricks and tiles were the first variety of reactive mineral additives for lime, gypsum and materials based on them [1, 2]. In the following millennia and up to the pres-ent time, natural pozzolans – volcanic ash, pumice, tuff, trepel, diatomite, flask, route, by-products and wastes – metallurgical and fuel slags and ashes, etc., have been used primarily for lime- and Portland cement-based binder systems [3, 4]. Expected growth in Portland cement production up to 5-6 billion t by 2050, and its...

1 Introduction

Seven to eight thousand years ago, calcined clays in the form of flour from ceramic bricks and tiles were the first variety of reactive mineral additives for lime, gypsum and materials based on them [1, 2]. In the following millennia and up to the pres-ent time, natural pozzolans – volcanic ash, pumice, tuff, trepel, diatomite, flask, route, by-products and wastes – metallurgical and fuel slags and ashes, etc., have been used primarily for lime- and Portland cement-based binder systems [3, 4]. Expected growth in Portland cement production up to 5-6 billion t by 2050, and its increasing content of supplementary cementitious materials up to 30-40% [5, 6], are associated with the need to expand their use in volume and range. Uneven distribution and limited reserves of deposits in countries and regions of natural pozzolan resource, together with the formation of technogenic pozzolans for use as mineral additions cannot satisfy the increasing need for them [7]. In search of an alternative, investigations have recently been carried out on the effectiveness of pozzolans based on calcined clays, as evidenced by the 1st and 2nd international conferences of relevance, which were held in Lausanne in 2015 and Havana in 2017 [8, 9] and summed up the research results in this field. Studies in this field began in the USA and the USSR [10] in the 1940s and extensively expanded all around the world in the 1980s [3, 11-13]. The effectiveness of calcined kaolin, illite, bentonite clays, marls, loam and other varieties of clay and minerals - kaolinite, montmorillonite, illite [13-19] - have been stated by many researchers. Numerous studies and application practices have established the effectiveness of metakaolin [15, 19], obtained by calcination of kaolin clay at 650-700°C and ground to a specific surface of 1000 m2/kg or higher. However, the widespread production and use of metakaolin is hampered by the limited deposits and reserves of kaolin clays, including those within the Russian Federation [19]. In addition, kaolin is a valuable product for many industries and is therefore scarce and expensive for use in large-scale production of blended Portland cements and materials based on them. In recent years, this circumstance has led to systematic studies on the effectiveness of supplementary cementitious materials based on ubiquitous clays with either a different content of kaolinite or none at all [8, 16, 21-28] in many countries. Our studies proved [6, 23, 29-31] that individual varieties of calcined clays obtained by calcination of multimineral clays at temperatures of 400-800°C and ground up to 250-800 m2/kg with different kaolinite content are no less effective than metakaolin. In view of their widespread production and application, the influence of calcined clays, depending both on the composition of the clays and on the temperature of calcination on the properties of the Portland cement pastes, has, however, yet to be sufficiently studied.

This research is aimed at studying the properties of the widely employed multimineral clays as supplementary cementitious materials, depending on the calcination temperature and kaolin content, in comparison with reference samples and those incorporated with commercial metakaolin.

2 Materials and methods

The starting materials were as follows: Portland cement CEM I, the chemical and mineralogical compositions of which are shown in Table 1, i.e., specific surface area (Blaine): 345 cm2/g, normal consistency: 27%, initial setting time: 2 h 50 min, final setting time: 4 h 10 min.

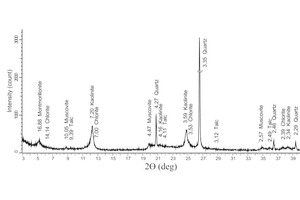

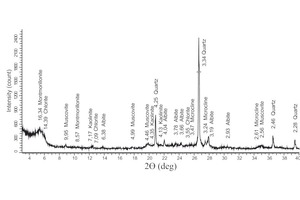

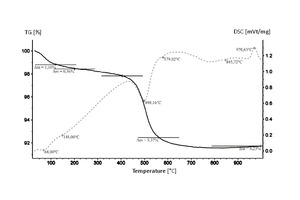

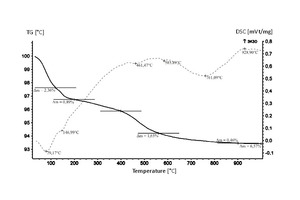

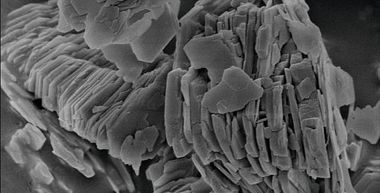

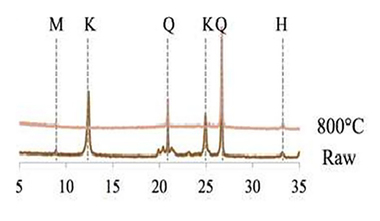

Calcined clays from five deposits in the Russian Federation – Nizhneuvel’skaya from the Chelyabinsk region (clay 1) and Saray-Chekurchinskaya (clay 2) from the Republic of Tatarstan. Their chemical and mineral compositions are shown in Tables 2 and 3. Figures 1 and 2 show the X-rays, and Figures 3 and 4 the thermal analysis of the clays.

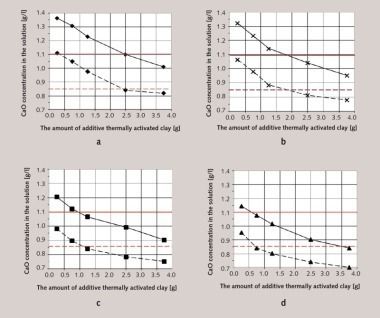

Metakaolin was produced by Sinergo (Russian Federation). For the chemical composition of the metakaolin, see Table 4. Its pozzolanic activity by calcium hydroxide [Ca(OH)2] was greater than 1000 mg/l, and the specific surface area was 1200 m²/kg.

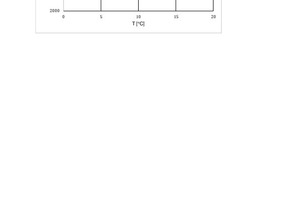

The clays were calcined at 100, 300, 400, 600, and 800°C up to constant weight. The heating rate was 1.7, 2.5, and 3.3 K/min, respectively. After calcination, the clays were cooled down to room temperature and ground in a planetary mill to 250 m²/kg.

The Portland cement pastes incorporated with metakaolin and calcined clays were prepared from fresh Portland cement pastes of normal consistency in cubic molds (2 cm x 2 cm x 2 cm). The compressive strength of the cubes was tested after steam curing. Prior to steam curing, the cubes were preset at 90 – 95 °C for 24 h. It took 4 h to reach the desired temperature, and a dwell time of 6 h was used. The cubes were then cooled to room temperature over a period of 3 h. The average compressive strength for each mixture at each testing stage was calculated on the basis of six measurements. The water resistance of the hardened Portland pastes was determined after steam curing, i.e., calculated from the ratio of the compressive strength of a water-saturated sample at temperature 20 – 22°C to the pre-saturation level in accordance with the method outlined in the Russian standard 30629-99 (Council of Standardization, Metrology and Specification, 1999). The water adsorption was determined from the ratio of the weight increase of samples after immersion in water to their dry weights (the samples having been dried to constant mass at a temperature of 102 – 105°C).

X-ray diffraction (XRD) was performed on crushed and blended Portland cement paste samples that had been aged for 28 days. XRD data were collected using a D2 phaser X-ray diffractometer in a θ–2θ configuration using the Bragg–Brentano method. The diffractometer used a Cu Kα radiation source and was operated at 40 kV and 30 mA. Data handling was performed by a Diffracplus Evaluation Package with an EVA search/match module. A PDF-2 ICDD database was used.

An STA443 F3 Jupiter simultaneous thermal analysis apparatus was used for establishing TG/DSC. The samples were heated from 30° C to 1000° C at a heating rate of 10 K/min. The data was analysed using Netzsch Proteus Thermal Analysis software.

3 Results and discussion

The physical-mechanical properties of the reference material and incorporated with 5 – 20 % of metakaolin and calcined clays hardened Portland cement pastes are described in the following section.

Table 5 highlights the effect of metakaolin incorporation on the properties of Portland cement paste. Tables 6 and 7 and Figures 5 to 12 show the effect of calcined clay incorporation on the properties of Portland cement paste. From an analysis of the data shown in these tables and figures, the following conclusions can be drawn:

Drying temperature 100° C

Dried at 100° C, additions of 5 – 10 % clay 1 into Portland cement did not decrease the compressive strength, whereas additions of 15 – 20% decreased it by more than 20%; whereas additions of 5 – 20 % reduced the density by 3 – 6% and the water resistance to 0.9 – 0.84 and increased the water adsorption by 4 – 8 %.

Calcined at 300° C, additions of 5 – 15 % of clay 2 into Portland cement did not affect the water resistance of the hardened Portland cement paste; additions of 5 – 20 % lower than additions of clay 1 decreased the density, increased the water adsorption and much more markedly reduced the compressive strength of the Portland cement paste.

Drying temperature 300° C

The additions of 5 – 15 % clay 1 calcined at 300° C increased the density of the Portland cement paste by 2 – 5 %, expanded the water adsorption by 1.6 – 1.7 % points, the compressive strength by as much as 32 – 33 %, and the water resistance from 0.92 to 0.96 – 0.94 %.

The additions of 5 – 10 % clay 2 calcined at 300° C slightly improved the compressive strength of hardened Portland cement paste; additions of 5 – 20 % increased the density by up to 3 – 2 %; the water adsorption from 1 to 2.4 - 2.9 % and altered the water resistance from 0.92 to 0.96 – 0.93, while additions of 15 – 20 % decreased the compressive strength by 12.5 – 25.5 %.

Drying temperature 400° C

The additions of 5 – 15 % clay 1 calcined at 400°C improved the compressive strength of the hardened Portland cement paste by 20 – 3.5 %, raised the water adsorption up to 2.0 – 2.3 % and the water resistance up to 0.95 – 0.94; the addition of 5 – 20% decreased density by 2 %; the addition of 20 % reduced the compressive strength by 20 %.

The additions of 5 – 15 % clay 2 calcined at 400° C improved the compressive strength of the hardened Portland cement paste by 43.4 – 11.8 %; raised the water adsorption up to 2.0 – 2.25 % the water resistance up to 0.975 – 0.96 and the density by 3.1 – 0.7 %.

Drying temperature 600° C

The additions of 5-20 % clay 1 calcined at 600° C improved the compressive strength of the hardened Portland cement paste by 49.1 – 16.2 % and the water adsorption by up to 1.21 – 2.5 % points, raised the water resistance up to 0.96 – 0.94 and reduced the density by 0.2 – 4 %.

The additions of 5 – 20 % clay 2 calcined at 600° C improved the compressive strength of the hardened Portland cement paste by 12 – 0.2%; raised the water adsorption to 1.0 – 1.2 % and the water resistance up to 0.94 – 0.93 while slightly reducing the density.

Drying temperature 800° C

The additions of 5 – 15 % clay 1 calcined at 800°C improved the compressive strength of the hardened Portland cement paste by 33.5 – 20 %; increased the water adsorption to 1.11 – 1.32 % and the water resistance to 0.95 – 0.92 and reduced the density by 2 – 4 %.

The additions of 5 – 20 % clay 2 calcined at 800° C improved the compressive strength of the hardened Portland cement paste by 29 – 5 %; raised the water adsorption to 1.80 – 1.85 % and the water resistance to 0.95 – 0.96 and reduced the density by 2.0 – 0.9 %.

The additions of clay 1 calcined at 600°C were more effective at improving the physical-technical properties of hardened Portland cement paste than was clay 1 calcined at 300° C, 400° C and 800° C. Additions calcined at 300° C were more reactive than those calcined at 400° C.

The additions of clay 2 calcined at 400° C provided higher properties of hardened Portland cement paste than did those calcined at 300° C, 600° C and 800° C.

The additions of clay 2 calcined at 400° C and 800° C provided higher properties of hardened Portland cement paste than did clay 1 calcined at the same temperatures.

The additions of clay 1 calcined at 600° C provided higher properties of hardened Portland cement paste than did clay 2 calcined at the same temperatures.

Regarding the effect of the clays and metakaolin, the comparison of the results demonstrates that the hardened Portland cement pastes incorporated with 5 – 20% clay 1 and 2 had lower compressive strength, water resistance, and higher water adsorption than those introduced with metakaolin.

The additions of 5 – 20 % clay 1 calcined at 300° C, compared to the same amount of metakaolin, increased the compressive strength by 3.4 – 16.5 % and density by 3.7 – 7 %, and decreased the water adsorption of the hardened Portland cement pastes by 6.0 – 31 %.

The additions of 5 – 20 % clay 2 calcined at 300° C were better than metakaolin at increasing the density of the hardened Portland cement paste by 0.8 – 8.3 %, but they increased its water adsorption up to 4.1 – 4.3 % and reduced the strength of the hardened Portland cement paste by 19.0 – 12.2 %.

The additions of 5 – 20 % clay 1 calcined at 400°C decreased the compressive strength of the hardened Portland cement pastes by 8.0 - 9.1 %, the additions of 10 and 15 % increased the compressive strength by 12.7 – 11.4 %, the additions of 5 – 20 % increased water adsorption up to 18.0 – 3.3 % compared to metakaolin-introduced samples.

The additions of 5 – 20 % clay 2 calcined at 400°C were more effective compared to metakaolin at improving the compressive strength of the hardened Portland cement pastes by 12.4 – 26.4 % accompanied by an increase in density by 1.8 – 8.1 % and water resistance from 0.92 – 0.96 to 0.97 – 0.975, plus a decrease in water adsorption by 30 %.

The additions of 5 – 20 % clay 1 calcined at 600° C increased the compressive strength by 10.5 – 49.6 %, the density by 1.1 – 5.7 %, and raised the water resistance up to 0.96 – 0.94 while decreasing the water adsorption of the hardened Portland cement pastes by 16.6 – 29.1 % compared to metakaolin introduced samples.

The additions of 10 – 20 % clay 2 calcined at 600° C increased the compressive strength by 0.9 – 16.5% and the density by 2.3 – 6.5 % while decreasing the water adsorption of the hardened Portland cement pastes by 35 – 66.6 % compared to metakaolin introduced samples..

The additions of 10 – 20 % clay 1 calcined at 800° C increased the compressive strength by 15.9 – 5.1 % and decreased the water adsorption of the hardened Portland cement pastes by 3.4 – 7.9 % compared to metakaolin introduced samples.

The additions of 5 – 10 % clay 2 calcined at 800° C increased the compressive strength by 0.3 – 28.5 % and the density of the hardened Portland cement paste by 3.4 – 7.9 % compared to metakaolin introduced samples.

4 Conclusion

In most cases, the hardened Portland cement pastes incorporated with additions of 5 – 20 % multimineral clays containing 33.7 and 3.41 % of kaolinite calcined at 300 – 800° C and ground to 250 m2/kg have higher physical-technical properties than those of the reference samples.

The clay containing 3.41 % of kaolinite displays higher reactivity compared to clay containing 33.7 % of kaolinite at the same temperature of thermal treatment.

The influence of calcined clays on the properties of the hardened Portland cement pastes is not proportional to its content and calcination temperature.

The pozzolanic reactivity of the clays containing a higher content of kaolinite is at its highest after calcination at temperatures of 300 and 600° C, whereas clays containing a lower content of kaolinite are most reactive after calcination at a temperature of 400° C.

More than 70 % of the hardened Portland cement paste samples incorporated with clays calcined at 300 – 800° C and ground to 250 m2/kg have superior physical-technical properties compared to those introduced with metakaolin obtained at 700° C and ground to 1000 m2/kg. The clay containing 33.7 % of kaolinite calcined at 300° C and clay containing 3.41 % calcined at 400° C and ground to 250 m2/kg were found to be more reactive than metakaolin with a fineness 1000 m2/kg.

Based on the results presented, it can be concluded that pozzolans known to be compatible in reactivity with metakaolin can be obtained from widely available multimineral clays.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.