Solid Alternative Fuels – legal, technological and economical developments in Austria

This contribution describes the legal, material, plant and economic developments and properties as well as the quality assurance of solid alternative fuels, as there are ‘Solid Recovered Fuel (SRF)’ with a quality and grain size matching the requirements for main burners and ‘Residue Derived Fuel (RDF)’ with an appropriate coarser grain size for feeding the calciner in the pyroprocess of a cement kiln.

1 Introduction

The European Union Directive 2000/76/EC on incineration of waste [EC, 2000] limits air pollution only, however at that time there were no limits considering the levels of pollutants in fuels, residues or products themselves when waste derived fuels are burnt in co-incineration plants. To overcome this shortage, the Guideline for Waste Derived Fuels [BMLFUW, 2008] and the Waste Incineration Directive [BMLFUW, 2010], which define quality criteria for “waste derived fuels” burnt in co-incineration plants, have been issued in Austria in nowadays [Lorber et al., 2012].

According to...

1 Introduction

The European Union Directive 2000/76/EC on incineration of waste [EC, 2000] limits air pollution only, however at that time there were no limits considering the levels of pollutants in fuels, residues or products themselves when waste derived fuels are burnt in co-incineration plants. To overcome this shortage, the Guideline for Waste Derived Fuels [BMLFUW, 2008] and the Waste Incineration Directive [BMLFUW, 2010], which define quality criteria for “waste derived fuels” burnt in co-incineration plants, have been issued in Austria in nowadays [Lorber et al., 2012].

According to this legal framework, “waste derived fuels” are still waste which is used entirely or to a relevant extent for the purpose of energy generation and which satisfies the quality criteria laid down in the “Waste Incineration Directive” [BMLFUW, 2010].

Thus, the composition of waste derived fuels is restricted by limit values (i.e. pollutant content per net calorific value (mg/MJDM) for Sb, As, Pb, Cd, Cr, Co, Ni, Hg and a distinction is made for three different types of co-incineration plants, namely cement kilns, power stations and other thermal facilities. Before waste becomes a waste derived fuel that can be used in a co-incineration plant, it usually undergoes pre-treatment by preparation and manufacturing. Preparation of solid waste to an alternative fuel includes classifying, sorting and separation of ferrous and non-ferrous metals as well as heavyweight of inert materials. Manufacturing, which includes crushing, drying and soft pelletizing, is a pre-processing of waste to improve the alternative fuel’s feeding and incineration properties. Waste derived fuels with a low level of pollutants (i.e. after multiple preparation steps) may become a ‘substitution fuel product’ which can be released out of the waste regime. Solid alternative fuels (SRF/RDF/HCF) are waste derived fuels, having a net calorific value (LHV) between ca. 11 and >25 MJ/kgOS and a particle size (d95) range from <5mm to <300mm, which is normally prepared from high calorific fractions (HCF) of municipal, commercial or industrial waste (C&IW) materials that satisfies certain fuel quality criteria laid down as limited values in legal regulations, guidelines or specifications. [Lorber et al., 2012].

This paper sets its main focus on SRF/RDF production used in the cement industry. In Austria co-processing of SRF/RDF in the rotary kiln of cement works already has a long tradition with a thermal substitution rate (TSR) more than 65.3 % of the primary fuel consumption in 2011 [Mauschitz, 2012]. In the meantime, emission trading (Directive 2003/87 EC [EC, 2003]) has opened a new scope for use of SRF/RDF, because due to its relatively high biomass content (between 30 and 55 %, depending on calorific value), emission certificates can be saved by co-incinerators when using SRF/RDF. Even higher biogenic portions may be achieved for specific commercial and industrial waste and SRF/RDF specifically processed in order to gain higher biogenic content [Pieber et al., 2011, 2012]. There is also a great opportunity for SRF/RDF in developing countries where huge amounts of high calorific waste is still deposited by dumping or in regulated landfilling [Dorn et al., 2012].

Three fundamental conditions must be fulfilled before a plant operator is ready to opt for co-incineration of alternative fuels (which requires considerable investment). The conditions are [Baier, 2006]:

Legal compliance but also legal certainty,

Security of supply,

Assured quality [Lorber et al., 2012].

Co-processing, although burning of waste, is largely accepted by the society in Austria and some middle- and northern European countries (e.g., Germany, Switzerland, Belgium and Scandinavian countries). This is also reflected by the fact that approval processes for the use of SRF/RDF have not initiated specific resistance of the community or the media in recent years. The pioneer phase of waste-to-energy is over and nowadays the technology of co-incineration is optimized and improved to increase the TSR and expand the fields of SRF/RDF application.

2 Current state of Solid Alternative

Fuels (SRF/RDF)

According to the Federal Waste Management Plan [BMLFUW, 2006 - Status Report 2009], 1.665 million tpy of waste was processed in Austrian thermal plants in 2009, namely:

1 270 000 tpy: residual and bulky waste,

225 000 tpy: high-calorific fraction from waste

sorting or residual waste splitting,

170 000 tpy: thermally useful residues from

sorting of separately collected waste.

Additionally, 24 processing plants for “primarily mechanical treatment” of mixed municipal and commercial waste, with a total processing capacity of 1 224 000 tpy, are in operation. In 14 examined mechanical processing plants, HCF or SRF/RDF are processed for further external material recovery or thermal treatment with a total processing capacity of 765 500 tpy.

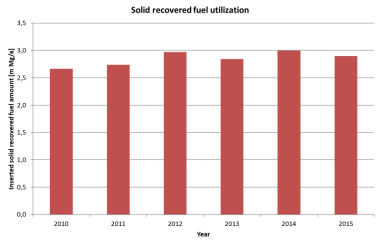

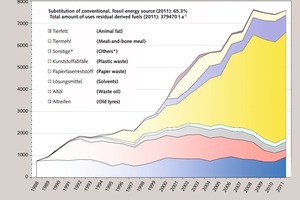

In Austria, 11 cement works, with a total plant capacity of 5 086 900 tpy (VÖZ, 2011) are in operation, and 4 426 944 tpy cement products with a clinker factor 0.717 tclinker per tcement were produced. Time related developments in application of SRF/RDF, especially made out of pre-treated plastic waste, in cement kilns is shown in Figure 1.

As mentioned before, co-processing in the cement industry has a long tradition in Austria. Figure 2 shows the thermal substitution rate and trends in utilization of different types of alternative fuel in cement kilns worldwide. Austria (2011: TSR 65.3 % [Mauschitz, 2012]) and Germany (2012: TSR 62.5 % [VDZ, 2013]) are clearly breaking the EU 27 average, as well as the global data for the EU 2006: 18 %, North America: 11 %, Japan: 11%, Australia: 11 % and Asia: 4 % [VÖZ, 2010]. It can be expected in the EU 27, as well as global TSR for primary energy consumption will be increased in future.

3 SRF/RDF Developments

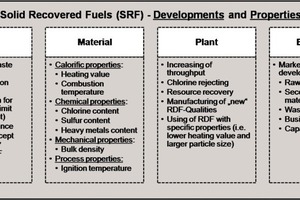

Modern production, marketing, application and quality assurance of SRF/RDF are intensive processes which are directly connected with certain legal, material, plant and economic developments and properties (Figure 3).

4 Legal developments

In 2008, after extensive discussions, a technical Guideline for Waste Derived Fuels was issued by Austrian BMLFUW [BMLFUW, 2008]. The production and use of SRF/RDF is regulated and controlled by this guideline. At the beginning, it was not legally binding, but the state of the art was defined by it and the approval procedures were using it as reference. In 2010 the contents of the guideline including important regulations for the “end-of-waste” declaration (products of Residual Derived Fuels) were implemented in the already existing Waste Incineration Directive [BMLFUW, 2010].

Among others the Waste Incineration Directive defines the input quality criteria (specified limit values) for SRF/RDF burnt in co-incineration plants as in kilns for cement production, power stations and other co-incineration plants. Waste derived fuel can only be used if the co-incineration plant operator has a validated quality assessment certificate. This certificate contains information about origin of waste, used treatment procedures, sampling data, analysis data and evaluation of waste quality. If all limited values are observed and technical requirements are fulfilled, waste derived fuel can be used for co-incineration.

The composition of waste derived fuels is restricted by limited values (i.e. pollutant content per net calorific value [mg/MJDM]). Additionally, statistic methods (i.e. median and 80th percentile) for the determination and the compliance of parameters with the limited value are given. At least 10 parallel analysis results are needed for statistical evaluation and assessment of waste derived fuel quality.

Waste derived fuel must fulfill all requirements defined in the Waste Incineration Directive [BMLFUW, 2010]. If SRF/RDF has a similar material and chemical composition and quality as conventional, fossil fuel, the waste owner has the opportunity to declare the so-called “End-of-Waste” status to leave the legal waste regime. When the declaration process is finished and all requirements are fulfilled and accepted by the authorities, the waste derived fuel is classified as a “SRF/RDF-product” and can be used in a specified process.

5 Material developments

Material properties and quality of SRF/RDF can be described by calorific value, chemical, mechanical and process parameters, which are also relevant for the classification of different waste derived fuel types. By using SRF/RDF the amount of conventional, fossil fuels can be reduced, significantly. In the case of a low TSR a low grate SRF/RDF can be compensated by higher quality of other fuels. The higher the thermal substitution rate is, the more restrictive are the quality requirements for waste derived fuels including the material handling technologies.

The challenge and development of modern waste management in respect of waste quality may be described as follows [Pomberger, 2012]:

Decreasing of calorific values: Reasons for decreasing of SRF/RDF calorific values in recent years are increased demand and higher prices for plastics, used for material recycling processes. In the past years, material recycling of high quality plastics has become an attractive waste management option. Consequently, the content of plastics with high calorific values in the feedstock waste for SRF/RDF is decreasing, but the biological portion is increasing. The main reasons for reported changes are, that waste streams from Mechanical Biological Treatment plants (MBT), which usually process solid household waste with high biological content, have been increased.

Exacerbate problem of chlorine: Increasing usage of packagings which contain chlorine (i.e. PVC-packagings) leads to quality degradation. Because of different consumer behaviour in different countries and waste imports from these countries, the SRF/RDF quality has been changed. Increasing of chlorine content has to be compensated and limited by using modern automatic sorting systems and applying sampling concepts including chemical analysis or the co-processing plant has to invest in a by-pass system.

Metal fractions and heavy metal content: Despite multiple metal sorting procedures (magnetic separator for iron and eddy-current separator for non-iron), the presence of metal (i.e. metal, heavy metal or heavy metal containing alloys) is still a problem of high quality SRF/RDF. Depending on the element, different percentages of heavy metals are bound to the metallic fraction but are also part of color pigments printed on and filled in polymeres.

Contaminants by hazardous waste: Waste oil and solvents have been used in cement kilns as liquid waste derived fuels for an extended period of time. Solid waste, which is contaminated by waste oil and solvents, was according to the Austrian law, stigmatized as “hazardous” because of its harmful properties, and could not be used as waste derived fuel. For example, due to proper mechanical pre-treatment of hazardous car workshop waste, quality monitored SRF/RDF can be manufactured nowadays for valorisation in cement kilns, again.

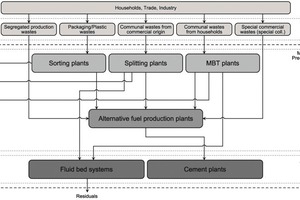

A modern waste management is a system of elements with mutual dependencies. Thus, a large waste management company requires a combination of different plant types. Each individual system is interrelated and interdependent. The plants are both elements but also subsystems of the overall system “Thermal utilization of wastes”. The connections between the systems are material- and freight-flows. In Figure 4, the system “Thermal utilization of waste” is depicted by the example of an Austrian waste management company. The assignment of waste streams to the appropriate plant types is made according to the quality of wastes [Pomberger, 2004].

Splitting plants pre-treating mixed commercial and industrial waste operate on the principle of qualitative splitting. They produce a tailored furnace-ready, medium-calorific solid alternative fuel for a fluidized bed combustion, as well as a high-calorific light fraction for the subsequent SRF-production for the main burner of a rotary kiln. The waste delivered to the splitting plant consists of mixed waste originating from commercial and industrial sources. The accepted waste for pre-processing can be described by the following properties: low moisture, low organic fraction, good processability, high calorific value. Determining sub-fractions are plastics, paper, cardboard, wood, metals and parts of minerals.

6 Classification of SRF/RDF

There are different methods of classifying the different types and quality classes of SRF/RDF used for co-incineration in various industrial sectors (e.g. CEN/TR15508 [CEN, 2006] or CENprEN 15359 [CEN, 2010]).

For practical reasons, the classification systems are shown in Table 1, which is based on the net calorific value and particle size as the main criteria.

7 Production plant developments

The SRF/RDF properties can be influenced in two different ways, namely by:

the selection of suitable waste streams, which contain high calorific components (e.g., paper, plastics, wood), or

using specialized mechanical treatment techniques, which are designed for selective removal of unwanted fractions (e.g., PVC-plastics) or wanted recyclable material (e.g. PET, plastics etc.).

Modern specialized mechanical pre-treatment techniques are responsible for different developments in waste management [Pomberger, 2012]:

Increasing of throughput: The ongoing increases in production and capacities are a result of increased modern industrialization. This can be shown by the ThermoTeam SRF/RDF-production plant. Since its opening in 2003, the plant was optimized by equipment with higher efficiency and the production capacity expanded to approx. 95 000 tpy in 2011.

Chlorine rejecting: By application of modern sensor-based sorting technologies, i,e, Near-Infrared (NIR) technology, the fractions with a higher rate of organic chlorine - such as PVC - can be removed of during processing of the waste stream. By removal of those PVC-containing fractions, the output quality of SRF/RDF production plant is stabilized and simultaneously increased.

Resource recovery from SRF/RDF: Waste is in parallel a resource for material recycling. Investigations have shown that considerable quantities of plastics (e.g., PET) and alumina are included in SRF/RDF-materials. Approximately, 2 to 3 % of PET and around 0.1 to 0.15 % of alumina are to be found in SRF/RDF, which is currently burnt in cement kilns. These materials are valuable resources and should be used in material recovery processes.

Production of RDF for calciner combustion: Another option to increase the thermal substitution rate by alternative fuels in a kiln is to use RDF (<80 mm) in secondary firing of the pre-heating. The development of especially designed calciners and combustion chambers or add-ons, like HOTDISC or PREPOL, enables further use of middle-calorific-RDF and High Calorific Fractions (HCF, <300mm, CV ~15 MJ/kg) with relative low grade requirements, but still with a higher calorific value than in comparison to fluidized bed incineration. The Holcim Ltd. cement plant located in Rohožnik (SK), which has implemented the HOTDISC-technology for incineration of low grade HCF with larger particle size (d95 <300 mm) is already playing a certain role in Slovakian and Austrian waste management.

Obviously, further important developments are in logistics, e.g. compression devices for better truck loading factor to the EU-maximum capacity of 40 t (appr. 23 t per 90m3); and fire prevention technology as there are detection sensors to monitor self-ignition temperature and its required installations.

In the future, a thermal substitution rate of 100 % SRF and RDF and HCF in cement kilns seems to be a realistic target. In Retznei (A), the total thermal energy supply for the cement kiln only by using solid and liquid alternative, non-fossil fuels was successful tested for one week.

8 Economic developments

Secondary raw materials obtain their economical relevance by substituting primary resources and cutting production costs. Regarding the latter, not only the European economies and industries are especially interested. This results in a demand for comparatively inexpensive raw materials. It is the waste industry that needs to deliver such raw materials derived from waste in different quantities and qualities. To be able to cover this demand, companies need an appropriate model that depicts the development of individual secondary raw materials from waste and allows statements concerning their future trends reaching from waste to the resource market. Such a system would enable companies to assess and plan the required capacities to be installed for the secondary raw materials on demand [Klampfl-Pernold, 2011].

9 Capacity Model

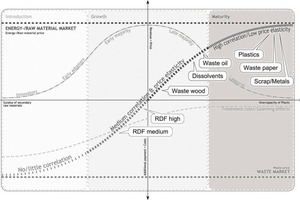

The so called Capacity Model is the basis for generating hypotheses regarding the interdependencies between primary and secondary raw material markets, combining conclusions to be applied from the so called “S-curve” (Fig. 5) and Life-Cycle-Models.

In support of the Life-Cycle-Concept, the Capacity Model establishes an explanatory approach for the interdependencies between primary and secondary raw material markets alongside the life cycle of different waste fractions (Fig. 5). Depending on plant capacity and waste amount, the price for waste is either determined by the markets for disposal or for energy and for raw material. Consequently, the price is geared towards the disposal and treatment costs or towards the price for substitution of primary resources [Klampfl-Pernold, 2011].

10 Necessity of quality assurance

As mentioned before, in Austria the legal framework for the use of SRF, RDF and HCF is laid down in the regulations issued by the Ministry of Environment [BMLFUW] in 2008 and 2010 and by standards (ÖNORM) published by the Austrian Standards Institute (ASI) (e.g., ÖNORM EN 15442 [ASI, 2011a] and ÖNORM EN 15443 [ASI, 2011b]). By definition, waste derived fuels are waste that is used entirely or to a relevant extent for the purpose of energy generation and which satisfies the defined quality criteria [BMLFUW, 2008].

Apart from legal requirements, additional fuel specifications are usually fixed in the contract between SRF/RDF supplier and user, which normally contain:

Particle size (d95) or (d90), net calorific value (MJ/kgOS), chlorine content (w%DM), sulfur content (w%DM), biogenic carbon content (%), ash content (w%DM), water content (w%OS), as well as restrictions (mg/kgDM) for the heavy metals (As, Sb, Pb, Cd, Cr, Co, Cu, Zn, Ni, Hg, Tl, V, Sn, Mn) [Lorber, et al., 2012].

Ensuring the necessary legal compliance with the limit values and specifications given in the suppliers contract requires a proper monitoring procedure for SRF/RDF. For this, two different approaches are common [Lorber, et al., 2012]:

Supplier control: External quality control of SRF/RDF for legal compliance is done by the supplier, who forwarded all the relevant information to the consumer. In this case, the supplier has to elaborate a sampling plan and conduct all required analytical measurements, and the consumer has to take random samples of the incoming SRF/RDF in order to check the identity of the material. These cross checks have to be carried out at least once a year, minimum. If a contamination of the alternative fuel is suspected in the course of a visual check or in the case that it does not seem to comply with regulations, samples have to be taken and analyzed. For the identity check, the analytical examination (lot size) refers to a fuel amount of 150 t or – in case of mass streams >40000 tpy – to a daily average.

Consumer control: The incoming alternative fuel delivered by different suppliers is to be examined by the operator of the kiln itself. Therefore, sampling plans as well as a sample preparation concept has to be established according to standards and guidelines given by the authorities [comp. ASI, 2011a, 2011b; BMLFUW, 2008, 2010]. The amount and scope of analyses to be carried out for quality assurance depend strongly on the volume and frequency of SRF/RDF-deliveries to the plant. A sampling plan is to be set up according to CEN/TS 15442 [ASI, 2011a] for each type and source of SRF/RDF separately. For this, a distinction is made between the amount of the incoming SRF/RDF streams larger than 40 000 tpy and less than 40 000 tpy.

Summary

Production and utilization of alternative fuels show a strong positive development in Austria as well as in other regions of the world. It has become state of the art in the European cement industry and from the economical point of view it is hardly impossible to operate a cement kiln without substitution of conventional fossil fuels. Co-processing has become a economic necessity and a generally accepted part of a national wide waste management, in Austria and other European countries.

Although there are still problems in emerging countries as well as in developing countries with public acceptance of co-processing, however an increase of the TSR can be expected in near future. It is a social process rather than a technical one to accept these innovative developments and changes in waste management.

Some countries still have to provide fundamental requirements and to set the stage for production and use of alternative fuels. Suitable waste streams have to be generated by collection as separation systems, which have to be erected and financed. Fuel production and use is part of a complex waste management system, which is currently at different levels of development depending on the type of country and its players.

The availability of appropriate waste streams will be a main challenge for the future. It is a paradox that by politically enforced avoidance waste became a “scarce good”. Its demand is still increasing and as a result of this, the competition for capable waste streams will become stronger in future. This also puts the principle and strategy of “waste prevention” under a new light.

However, there is no doubt that alternative fuel consumption will increase worldwide. It will become more and more accepted, it will become an important part of proactive waste management systems and it will contribute to a higher energy efficiency in all industrial sectors.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![2 Comparison of thermal substitution rates [%] for co-processing (2000-2011) [Note: ‘CPP’ means integrated cement production line]](https://www.zkg-online.info/imgs/tok_dbaacc06baa5f1243d7dd9bf9b19951c/w300_h200_x218_y104_101538905_86e3f1c80c.jpg)