Raising the quality of calcium silicate units with simultaneous reduction

of production costs using Statistical

Design of Experiments (DoE)

Fundamental investigations were carried out to optimise the production process for calcium silicate units with the aim of saving costs and energy. The statistical design of experiments (DoE) approach was employed because of the large number of possible variations, and a mathematical model was set up. This model can be used to predict the brick compressive strength.

1 Introduction

Calcium silicate units are masonry blocks formed from burnt lime and silicate raw materials that are autoclaved in an atmosphere of high-pressure steam at approx. 200°C and 16 bar. The autoclaving process results in the formation of calcium silicate hydrate phases (CSH phases), which are responsible for the necessary compressive strength. The autoclaving process defines the setting reactions of the calcium silicate units and accelerates the formation of the CSH phases [1]. This process is a very energy- and cost-intensive factor for the manufacturing industry. Optimally...

1 Introduction

Calcium silicate units are masonry blocks formed from burnt lime and silicate raw materials that are autoclaved in an atmosphere of high-pressure steam at approx. 200°C and 16 bar. The autoclaving process results in the formation of calcium silicate hydrate phases (CSH phases), which are responsible for the necessary compressive strength. The autoclaving process defines the setting reactions of the calcium silicate units and accelerates the formation of the CSH phases [1]. This process is a very energy- and cost-intensive factor for the manufacturing industry. Optimally interacting setting of production parameters must be found and evaluated in order to minimize production costs. A constant product quality must be guaranteed while at the same time reducing production costs. In the past, the technical parameters for the autoclaving of calcium silicate unit products were investigated exclusively from various individual aspects [2, 3, 4]. However, it has been clearly shown that relationships between the raw material properties, the parameters of autoclaving, the brick quality and the energy required for autoclaving are very complex and depend on numerous overlapping influencing variables and their interactions. These interrelationships between the above-mentioned variables represent a non-linear dynamic system. For this reason, algorithms must be developed in order to make predictions. As part of an IGF project of the “Forschungsvereinigung Kalk-Sand e.V.” (AiF-No. 18570-N) fundamental investigations were carried out to optimize the production process for calcium silicate units with the aim of saving costs and energy. Trials to optimize the hardening curves have already been carried out in various research projects [5, 6, 7]. In addition, there are publications on measures to reduce energy consumption and production-related CO2 emissions in the manufacture of calcium silicate units by energy optimization measures [4].

Due to the large number of possible variations, the statistical design of experiments (DoE) approach was used in this study to identify correlations between the individual parameters in a small number of trials and to optimize the product quality of the calcium silicate units in terms of costs [8]. So far, the approach of statistical design of experiments has mainly been used in other industries such as the automotive industry or in mechanical engineering [9, 10]. Links to the chemical and mineralogical processes taking place during hydrothermal hardening were also established in this project.

2 Test programme

The aim of the investigative programme was to minimize production costs, without loss of quality, by determining the influence of relevant parameters on a representative property, namely the compressive strength, of the end product.

2.1 The production parameters

and raw material mixes investigated

Several process parameters and raw material mixes were changed simultaneously in order to analyze the interrelationships in the autoclaving process. Sand and lime were varied both in type and proportion. Bandwidths for the production parameters regarded as relevant were determined for statistical design of experiments on the basis of experience as follows:

Proportions of sand, lime and water (mix components) totalling 100 %:

sand, 85 - 91 wt.%

lime, 5 - 9 wt.%

water, 4 - 6 wt.%

type of lime and type of sand mixture (categorial factors):

type of lime, CL90 or CL80

type of sand (5 representative sample mixes for a wide product range)

parameters that are involved in the autoclaving process (continuous factors) are

heating phase, 0.5 - 1.5 h

holding phase, 4 - 6 h

hardening pressure, 12 - 16 bar with correspondingly different temperatures

compacting pressure, 10 - 14 bar (only indirectly via the porosity created during compression)

2.2 Statistical Design of Experiments (DoE)

The compressive strength was selected as the response variable to be modelled as the main characteristic relevant to standards and costs. The design of experiments allows a prediction model for a response to be constructed from a small number of trials [9, 10]. Before creating a design, it is necessary to determine basic influencing variables and their possible effects on the response on the basis of expert knowledge.

Based on the chosen experimental range and a maximum model that considers main effects, two-way interactions and quadratic effects [12], several D-optimal design with a different number of central points were generated and compared using different statistical measures [9]. Central points reflect an average setting for numerical process parameters. Computer generated designs were necessary due to the limited experimental range of the mix parameters, [11]. Because of the smallest average prediction variance, the design with three central points was chosen (see Table 1).

Hence, with the help of design of experiments, a design with 72 experiments was created with the JMP software – instead of considering 7290 trials, which result from the combination of three different settings of the four continuous factors, nine mixtures and all levels of sand and lime type.

2.3 Preparation of test pieces

The test pieces were produced in DF format [DIN V 106] (dimensions: 240 x 115 x 52 mm3) and the raw material components were intensively homogenized with an Eirich mixer (type R80). The slaking of the lime-sand raw mixes took place for a period of t = 2 h at a temperature of T = 70 to 80 °C in a closed steel container in a heated cabinet. 10 calcium silicate unit blanks per mix were then produced using a laboratory calcium silicate unit press. After compaction with a hydraulic press, the blanks were hardened at varying temperatures and varying hardening pressures. The press moisture, the heating time and the holding time varied in accordance with 2.1, the relaxation time was te = 1 h in all cases. When the experiment was carried out, three test pieces did not initially harden due to an excessive water content and too low a compacting pressure. The corresponding experimental runs were successful repeated with a reduction of the water content from 6 wt% to 5 wt% and an increase of the lime content from 5 wt% to 6 wt% as well as of the compacting pressure from 10 bar to 12 bar.

2.4 Investigative programme for comparative

determination of chemical, mineralogical

and physical parameters

According to Gundlach [1], the strength-forming CSH phases mentioned below can occur in calcium silicate units and can be determined by X-ray diffraction.

In calcium silicate unit production – as in aerated concrete technology – this is most important strength-forming target phase [1, 11]:

Tobermorite: Ca5Si6O16(OH)2 · 4H2O or Ca5Si6(O,OH)18 · 5H2O

In [1, 11] it is indicated that the xonotlite phase also influences the strength formation of the calcium silicate unit structure; the influence is not known in detail:

Xonotlite: Ca6[(OH)2|Si6O17]

Various tests were carried out on the calcium silicate units and blanks produced.

2.4.1 Measurements on the calcium silicate unit blanks

Determination of the blank stability by means of a compression test

Measurement of the porosity of selected non-autoclaved blanks using high-resolution computer tomography (μ-CT).

2.4.2 Measurements on the calcium silicate units produced

Standard parameters specified in DIN EN 771-2 that are relevant to monitoring

Brick compressive strength and brick bulk density as specified in DIN EN 772-1 and -13

Freeze-thaw resistance as specified in DIN EN 772-18

Physical-chemical analysis

Thermoanalytical investigations for free radical control (DTA/DSC/TG)

Microstructure properties

Water absorption and shrinkage / elongation

Determination of the total porosity and pore radius distribution by high-pressure mercury intrusion porosimetry (MIP)

To characterize the microstructure and its formation, 20 calcium silicate units were selected from the 72 produced samples (based on maxima and minima of the manipulated variables) and analyzed chemico-mineralogically as follows:

Light microscopic investigations on thin sections (LM)

Phase formation by means of scanning electron microscopy (ESEM / REM)

Qualitative (XRD) and quantitative radiographic phase analysis (Rietveld)

3 Test results

3.1 Prediction model for compressive strength

A variable selection approach that combined different statistical methods and expertise was carried out so that only the important effects should be considered in the modelling of compressive strength. The selected model contains the main effects of all the variables considered, the quadratic effects of compaction pressure, hardening pressure and holding phase as well as some of their interactions. Table 2 shows the selected effects and gives an impression of their importance. The log value corresponds to -log10 (p-value) of the t-test, which checks whether a coefficient differs from 0. It can be seen that the mix components have the greatest influence on the compressive strength. Due to the restriction that the mix components must add up to 1, the proportion of lime is indirectly included in the other mix components. A compact summary of the model interpretation is given in the next section.

The model obtained an adjusted R2 of 0.904. The maximum value of the adjusted R2 is 1, so this indicates a good fit of the prediction model to the observed values. This is graphically validated by plotting the predicted values against the observed values (Figure 1).

3.2 Influence of production parameters on

the compressive strength

Due to numerous interactions and second-order effects, the relationship determined between the process parameters and the compressive strength is complex. The most noteworthy influences on the compressive strength (CS) can be summarized as follows:

Higher lime content leads to a higher CS

Interactions of the mix components: Increasing the water content leads to a higher CS if the lime content is high enough

Coarse sand mixes deliver the highest CS

Interactions of the lime and sand mixtures: CL90 results in slightly higher CS for finer sands, but slightly lower CS for coarser sands

Interaction between the heating phase and the sand mixtures: A longer heating phase increases the CS for finer sands, decreases it for coarser sands

The holding phase has a slightly non-linear influence with higher CS at the limits of the range under consideration

The hardening pressure has a slightly non-linear effect with lower CS at the limits of the range under consideration

The compacting pressure, holding phase and heating phase interact with the mix components

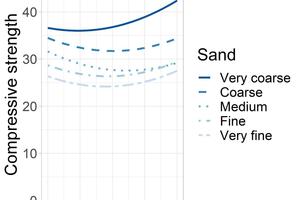

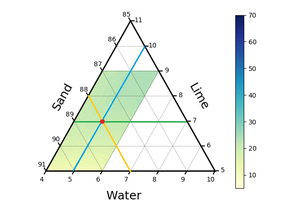

Figure 2 shows the interaction between the holding phase (x-axis) and the sand mixes (coded by colour and type of line). It can be seen that the holding phase has a slightly non-linear effect depending on the nature of the sand; a higher CS is more likely to be achieved with very short or very long holding phases. It can also be seen that coarser sands generally achieve a higher CS. Figure 3 shows the influence of the mix on the target variable using a ternary diagram. In a barycentric coordinate system [11] the colour gradient shows the level of compressive strength depending on the mix used. Each axis represents one mix component: The water content is represented by the lower axis, the lime content by the right and the sand content by the left axis. Each grid line within the triangle represents a constant value of the component whose scale lines are parallel to the grid line. The blue line runs parallel to the markings on the scale for the water content and therefore represents a constant value for the water content, in this case 5%. The mix composition at a given point is determined by the three grid lines that cross at that point. For example, the red point is crossed by the 7% grid line of the lime content (green), the 88% grid line of the sand content (yellow) and the 5% grid line of the water content (blue). Therefore the mix in this point consists of 5% water, 7% lime and 88% sand. The colouring around this point is in the compressive strength range of 24 N/mm². It can be seen that a higher lime content increases the CS, as the diagrams take on a greener shade towards the top of the diagram. Interactions between the mix components can also be seen: the CS increases slightly for a higher water content provided that a higher lime content is used, but decreases for a higher water content if a lower lime content is used.

Large-scale and detailed preliminary investigations must be carried out in each individual case before the findings presented here are transferred to operational production conditions.

3.3 Chemical-mineralogical investigations

on selected calcium silicate units

Chemical-mineralogical investigations have shown a correlation between the compressive strength and the phase compositions of the samples. To visualize the chemical-mineralogical properties a sample with good strength properties (KS+) and a sample with poor strength properties (KS-) were selected as examples in order to explain microstructural properties and phase contents in more detail.

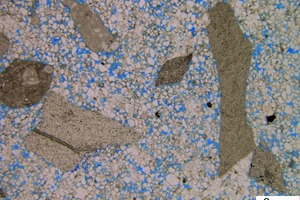

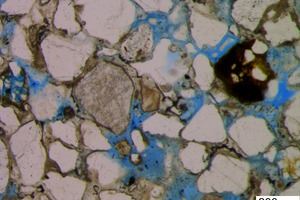

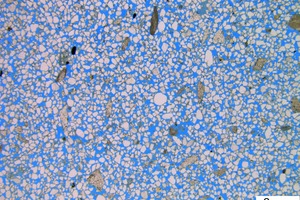

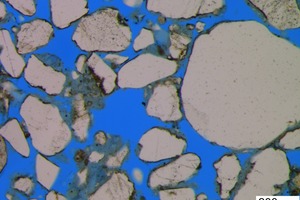

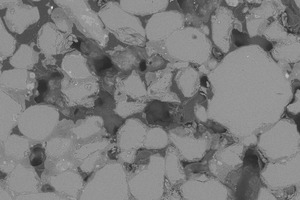

Different contents of the CSH phases could be determined optically in the light-microscopic examinations (LM) of thin sections of the calcium silicate units examined. It is noticeable that the calcium silicate unit samples with the highest strength values have a higher binder content between the sand grains. For example, the KS+ sample with a compressive strength of 42.8 N/mm² already showed a clearly visible CSH content due to the relatively high CaO input level of 9% by mass, see Figure 4, whereas the KS- (Figure 5) sample with a compressive strength of 14.8 N/mm² only shows a small CSH border around the sand grains, which suggests a reduced CSH phase formation due to the relatively low CaO input level of 5% by mass.

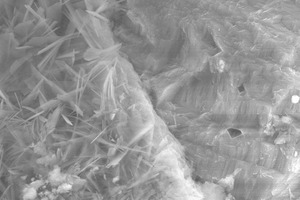

Scanning electron microscopic examinations show quartzite grains as the main component. Nearly all the grains show a surrounding border of reaction products of hydrothermal hardening (CSH phases). Figure 6 shows characteristic tobermorite crystals, size approx. 10 µm, from the KS+ sample.

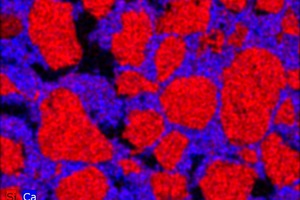

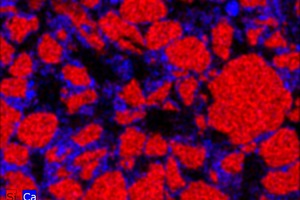

There are no qualitative differences between the microstructures of the 20 series investigated. However, clear differences in the quantitative composition of the CSH phases are perceptible and different pore contents can be seen in the scanning electron microscope images. The EDX results also confirm the results of the light microscopy. A clear border of the CSH phases around the quartz grain is visible in the KS+ sample (Figure 7) but with the KS- sample (Figure 8) only a small quantity of CSH phases can be detected.

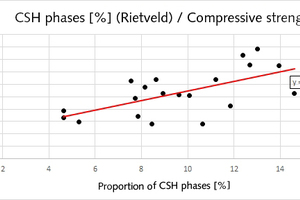

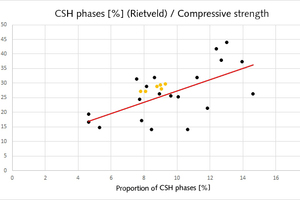

Figure 9 shows the compressive strength as a function of the CSH phases determined by Rietveld analysis. A clearly positive correlation can be seen here: the compressive strength increases with an increasing proportion of CSH phases. How the varied process and mix parameters affect the compressive strength, and therefore indirectly also the CSH phases, follows from 3.2.

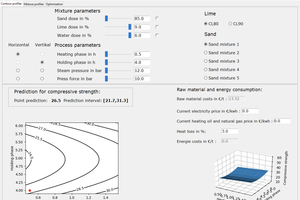

4 Development of the SPOAK software tool

In addition to the selection of a statistical model, an intuitive software tool was developed in which this model was implemented. It includes different displays of the model (see Figure 10), which are suitable for representing the compressive strength as a function of the mix components and as a function of two process parameters. The SPOAK software (Statistical Prediction and Optimization of the Autoclaving Process for Calcium Silicate Units) has been implemented as a Python application. The application enables the user to plan the production parameters within the bandwidths involved.

The primary components of the software are three windows for analysis of the effect of the process parameters (contour analysis), the mix (mix analysis) and the search for setting combinations with the desired compressive strength (optimization). In addition, a menu bar allows the use of general functions (e.g. open, save, undo, etc.). Process settings can be changed by means of sliders, manual input (upper part of the user interface) or a selection in the graphic. A 90% prediction interval is given in addition to the prediction of the compressive strength. Material costs and energy consumption are estimated after relevant variables are specified. In the Contour Analysis window, the main focus is on the change in compressive strength as a function of the process parameter, graphically supported by contour lines and surface plots (cf. Figure 10). In contrast, the Mix Analysis window shows ternary plots, as used in Figure 3. The Optimization window supports the search for a setting of the process and mix parameters close to the currently selected setting, but with a desired compressive strength within the test area.

5 Evaluation

Six samples (F1 - F6) with varying manufacturing parameters (cf. Table 3) were produced in a calcium silicate unit plant under real production conditions in order to evaluate the model and the findings.

On the assumption that the autoclaves have slightly different effects during the hardening times, the selectable values in the tool are transferred to a larger setting range, see Table 3. The deviation of the predicted values is less than 5 % except for the F1 series.

If the results of the radiographic Rietveld analyses are aligned with the results from test section 3, the F1 - F6 samples that were investigated are comparable with the previously examined samples with respect to their CSH phase fractions. The compressive strength can be predicted on the basis of the amount of CSH phase determined, see Figure 11.

6 Summary

As part of the investigations carried out, a mathematical model with which the brick compressive strength can be predicted was built up, examplarily on the basis of raw materials from a calcium silicate unit plant. All the relevant production parameters were varied using the methods of statistical design of experiments (DoE). The calculations carried out are based on the data records for the raw materials, generated from 72 experiments in the pilot plant, the process-related manufacturing parameters and the measured brick properties.

The energy required for a set of manufacturing parameters and the associated CO2 emissions can be calculated, so that the desired approaches for reducing energy consumption and environmentally relevant emissions as well as maintaining the quality for implementation in calcium silicate unit plants are available. These are - as far as technically possible - especially the

Reduction of energy consumption

Reduction of environmentally relevant emissions

Reduction of production costs by reducing the input of lime

Reduction of the manufacturing time by shortening the hardening time in the autoclave

Maintaining or increasing product quality, e.g. by optimizing the CSH phase constitution

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Predicted against observed values of compressive strength [N/mm²]](https://www.zkg-online.info/imgs/1/5/3/9/6/9/8/tok_0993bc07c092eb519c21e16c38bcca9d/w300_h200_x600_y600_Schade_NEUE_ABBILDUNG_fitplot-8dca9e51373c0de1.jpeg)