Current research findings on calcium-silicate unit production technology

The German research association Forschungsvereinigung Kalk-Sand e.V. (FVKS) has been involved in the development, production and testing of calcium-silicate masonry products for over 50 years now. Its paramount goals are to continuously improve and develop calcium-silicate production technology and construction applications. Its main tasks are to promote damage-free construction, further improve product quality, encourage innovative developments and identify measures for further reducing both the cost of production and energy consumption. This AiF research project provides an overview of the industry’s activities geared to practical implementation of those set goals.

1 Introduction

Calcium-silicate (CS) units are made from the starting materials sand, lime and water. The raw materials are proportioned by weight, intensively mixed together and fed into reactors on a conveying system. Within the reactor, quicklime is quenched under water consumption to obtain hydrated lime. The green units are then hardened under steam pressure at temperatures of the order of 200 °C for about four to eight hours, depending on the product’s geometry. The hot, steamy atmosphere dissolves silica from the quartz-sand grains, and the silica forms crystalline CSH phases with the...

1 Introduction

Calcium-silicate (CS) units are made from the starting materials sand, lime and water. The raw materials are proportioned by weight, intensively mixed together and fed into reactors on a conveying system. Within the reactor, quicklime is quenched under water consumption to obtain hydrated lime. The green units are then hardened under steam pressure at temperatures of the order of 200 °C for about four to eight hours, depending on the product’s geometry. The hot, steamy atmosphere dissolves silica from the quartz-sand grains, and the silica forms crystalline CSH phases with the hydrated lime, thereby firmly interlocking the grains of sand. After hardening and cooling, the calcium-silicate units are ready for use.

2 Production engineering

2.1 CSH-phase reaction accelerator II –

AiF No. 18413-N

The development of temperature-stable CSH reaction accelerators for industrial applications has made it possible to speed up the reactions that take place between the aggregates and the lime binder during autoclaving of green calcium-silicate units.

Such CSH-phase reaction accelerators can be injected directly into the production process. Since only a relatively small amount of CSH phases is required (e.g., 1 m% in relation to the lime dose), the cost incurred for the CSH phases, which are relatively easy to produce anyway, is quite limited and quickly compensated, particularly considering the rising cost of energy. Hence, the amount of energy consumed during to the autoclave holding phase can be reduced with no detriment to the quality of the calcium-silicate unit products. Reducing fuel consumption not only reduces the relevant costs, but also contributes to climate protection by reducing CO2 emissions accordingly [1, 2].

2.2 Ballistic resistance – AiF No. 18429-N

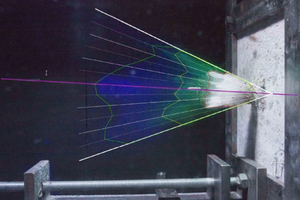

The primary objective of this research project was to experimentally determine the ballistic resistance of calcium-silicate units and calcium-silicate masonry using state-of-the-art methods as a basis for optimizing the composition of the units.

The results confirmed and extended the suitability of calcium-silicate units as building material for ”critical infrastructure” with security concerns, e.g., embassies, police stations, prisons, barracks and banks.

The technical approach to increasing the ballistic resistance of calcium-silicate brickwork was to modify the structure of commercially available calcium-silicate unit material with a maximum particle diameter of approx. 5 mm by addition of a defined coarse grain with diameters up to 16 mm. Adding significant quantities (20 to 45 mass%) of hard, coarse grain fractions (various quartz, bas-alt and magnetite gravels) produced a substantial gain in ballistic resistance.

In scientific terms, this phenomenon can be explained as follows: When a high-velocity projectile encounters a decidedly coarse structure, the coarse-grain fraction causes the projectile’s kinetic energy to be effectively distributed over a larger area, and the structural deformation resulting from conversion of the kinetic energy spreads out over a larger volume surrounding the point of impact. Consequently, the energy content of the projectile dissipates more quickly than it would in conventional calcium-silicate unit masonry. In other words, the blockwork’s resistance to ballistic projectiles is higher on the protected side.

The ballistic resistance of calcium-silicate masonry material is mainly dependent on the proportion of coarse gain (here: 8/16 mm) and on the type of rock in question (e.g., magnetite). The higher the coarse grain fraction, the higher the ballistic resistance. Clearly, the calcium-silicate unit formulation (sand/lime ratio, etc.) and the forming pressure applied to the raw mix are also important, but significantly less so than the coarse-grain content; see Figure 1 [3].

2.3 Heavy minerals for high sound insulation and radiation shielding – AiF No. 17798-N

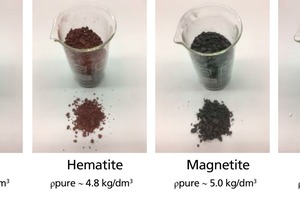

Conventional calcium-silicate units are made from the bulk raw materials lime, natural mineral aggregates and water. Quartz sand or crushed natural stone material such as basalt, diabase, gabbro and greywacke are normally used as aggregates for achieving higher raw densities. At maximum, raw densities (class 2.2) can be achieved with conventional silicate aggregates.

The suitability of natural aggregates containing iron or other heavy metal ions in their crystal lattices was investigated with a view to achieving particularly high stone bulk densities for exceptionally good sound insulation and for producing bricks with a shielding effect against electromagnetic or ionizing radiation. Such minerals are generally suitable for use in the production of building materials, e.g., baryte for heavyweight concrete. They are available in Germany and in several neighboring countries. This research project comprised a thorough investigation of heavy-mineral sands and of the relationships between the raw material properties of heavy mineral sands and conventional calcium-silicate unit raw materials, the production-processing parameters and the property values of calcium-silicate products were analyzed. The present results show that the use of various heavy mineral sands in the production of calcium-silicate units is basically feasible. Depending on the type of heavy mineral employed, the quantity added, its particle size distribution, its true density and other parameters of relevance, specimen units belonging to bulk density classes 2.2 and 2.4 (and, in extreme cases, even 2.8) were able to be produced under laboratory conditions. Potential efflorescence and discoloration must be taken into account; see Figure 2 [4].

2.4 Mixing – AiF No. 18187-N

This project investigated the question of which actuating variables determine the quality of cal-cium-silicate mixtures and which reciprocal effects those parameters have on each other.

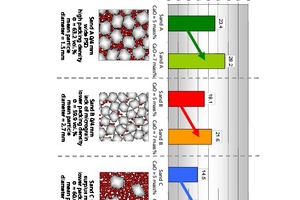

To that end, near-practice tests were first carried out in the laboratory, then at the pilot plant and, finally, at calcium-silicate brickworks. All in all, the mixing process itself can be considered relatively robust. Nevertheless, the tests revealed some clear optimization potentials for the actual operational/production scope. For example, series of tests performed on formulations determined by way of packing density calculations showed that a slight gain in the compressive strength of CS units can be achieved by extending the mixing time.

Shaping moisture offers an incomparably higher pertinent potential. The degree of envelopment (coverage) of the aggregates used with hydrated lime serves as a quality characteristic of calcium-silicate mixtures. It is readily quantifiable via digital image analysis in conjunction with scanning electron microscopy and EDX mapping. For example, the envelopment of the aggregates with hydrated lime increases significantly with each rise in lime fraction (CaO = 5 / 7 / 9 mass %) from 61 to 67 to 73 %. The crushing strength of the units therefore improves thanks to the availability of additional lime and, probably, to the higher degree of aggregate coverage with hydrated lime; see Figure 3.

No correlation was found to exist between the other mixing parameters (water content, mixing time, speed) and the compressive strength of the units. Investigations conducted at two calcium-silicate unit-making plants confirm the results of the laboratory and pilot plant test series [5].

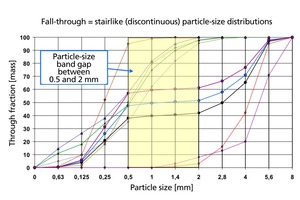

2.5 Gap grading – AiF-No. 18896-N

The cost-effective production of calcium-silicate units with high raw densities is of major importance for the construction of acoustically well-insulated masonry.

CS masonry products characterized by high strength, high bulk density and dimensional accuracy are needed in particular for building slender but especially strong load-bearing walls that require less than the usual installation space. As known from concrete and asphalt technology, so-called gap grading (involving irregular particle-size distributions, i.e., particle size band gaps) can be employed for producing mineral-base building materials with elevated apparent specific densities. Until now, calcium-silicate unit formulations have been based exclusively on homogeneous particle size distributions that yield calcium-silicate products with maximum raw densities of 2.0 to 2.2 kg/dm3. Transferring the favorable effect of gap grading, i.e., mixes exhibiting higher packing density and better compactibility, to calcium-silicate unit technology has now been shown to facilitate the achievement of higher bulk density classes 2.2 and 2.4 with less costly aggregates. With the aid of “BdP“ packing density software developed at the University of Kassel, simulation calculations and subsequent experimentation identified certain particle size band gaps (quantity, location and width) at which increased packing density can be observed. Within that context, the compaction behavior of lime-sand raw mixes was simulated using “RaSim” software developed at Clausthal Technical University for use in cement engineering geared to increasing packing density as described above. CS-unit production plants can look forward to corresponding cost reductions coupled with quality gains [6].

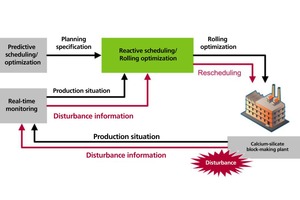

2.6 Material flow simulation II – AiF No. 20 EWN

The aim of this project is to adapt existing, successfully tested methodology for the purposes of material flow simulation at calcium-silicate construction material plants for purposes of production-process control and adjustment. Thus, orders are no longer to be introduced on the basis of an as-planned status, but instead oriented on the actual current state of production, with attention to resource optimization. This shop-floor simulation is also useful for automatically predicting or identifying deviations and, if necessary, counteracting them. Hence, the simulation tool facilitating long-term planning also finds its way into the short-term management of production processes. To that end, models based on the concept of IT infrastructure tailored to calcium-silicate unit production are developed and validated for real-time access to operating data. By coupling the simulations with algorithms based on the current production status, these models are able to quickly calculate resource-optimized production processes. Via the real-time connection, and with the aid of mathematical models, additional methods can be developed for forecasting or identifying deviations from the given production processes and reacting automatically to them with optimized rescheduling. All this is expected to yield a support-system methodology validated on various test models, by means of which production resources can be optimally dispatched with almost no need for personnel. In addition, the tool can be used to help secure investments/modernization and to monitor and control production.

Due to a lack of experts for developing the subject methodology, it has not yet been available to small and medium-size enterprises in particular. Now, though, thanks to continuous, automated monitoring and control, all operational processes can be maintained at resource-efficient levels, despite a continuing shortage of skilled workers and cost pressure; see Figure 5 [7, 8].

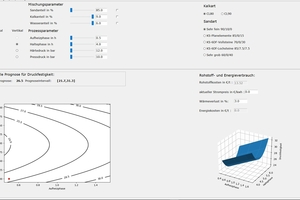

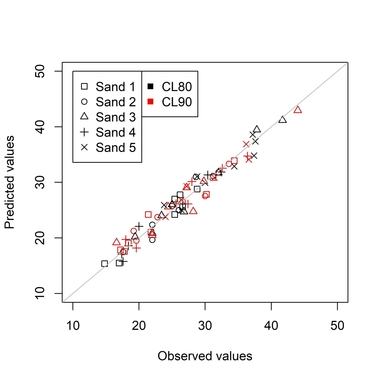

2.7 Statistical design of experiments – prognostication of CS unit properties – AiF No. 18570-N

In this project, for the first time ever, the multifactorial interrelationships of calcium-silicate unit production were systematically investigated by means of statistical experimental planning. The aim of the project is to further optimize the manufacturing process with a view to reducing the cost of production, the consumption of energy and environmentally relevant emissions. The following variations were introduced for that purpose:

a) three mixing factors:

sand content: 85 % to 91 %

lime content: 5 % to 9 %

water content: 4 % to 6 %

b) two categorical factors:

type of lime: CL90 or CL80

type of sand: 1, 2, 3, 4 or 5, and

c) four continuous factors:

heating phase: 0.5, 1, 1.5 h

holding phase: 4, 5, 6 h

hardening pressure: 12, 14, 16 bar

forming pressure: 10, 12, 14 bar

A D-optimal experimental plan comprising three central points was elaborated. Thus, the required number of experiments (pilot-scale production of calcium-silicate unit sample series) could be drastically reduced to 72 series. The primary command variable is unit compressive strength. This project has made it possible to model the interrelationships between raw material properties, process engineering production parameters and fundamental CS unit properties (compressive strength, bulk density, etc.) and to predict various quality parameters with good accuracy. Example: The forecasting tool can be used for zeroing in on various manufacturing parameters (particle size distribution curve, lime dose, forming pressure, and intensity of steam hardening). The software subsequently predicts the unit’s compressive strength; see Figure 6 [9].

//www.kalksandstein.de" target="_blank" >www.kalksandstein.de:www.kalksandstein.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.