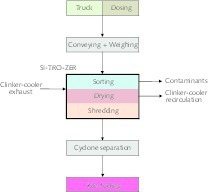

Processing route for ready-to-fire alternative fuels derived from waste fractions

Now, with the aid of simple technology for reducing the contaminant contents of all substitute-fuel fractions, an online conditioning process can be installed upstream of the kiln, simultaneously stabilizing the control system.

1 Introduction

For a long time now, alternative fuels in the form of RDF (refuse-derived fuel), more often referred to as SRF (solid-recovered/specified-recovered fuel), stemming from processed municipal and industrial/commercial waste have been in use as supplementary sources of energy in the cement industry.

Household and industrial/commercial waste volumes are treated, inter alia, according to the following basic processing operations:

mechanical conditioning and fractionation

biodegradation

thermal drying

mechanical/physical fractionation

At diverse European waste treatment facilities, a...

1 Introduction

For a long time now, alternative fuels in the form of RDF (refuse-derived fuel), more often referred to as SRF (solid-recovered/specified-recovered fuel), stemming from processed municipal and industrial/commercial waste have been in use as supplementary sources of energy in the cement industry.

Household and industrial/commercial waste volumes are treated, inter alia, according to the following basic processing operations:

mechanical conditioning and fractionation

biodegradation

thermal drying

mechanical/physical fractionation

At diverse European waste treatment facilities, a secondary fuel suited for application in industrial firing systems and power plants is being produced and readied for use. The technology needed for producing such secondary fuel is always dependent on the specified nature of the fuel to be generated. The products are dried to obtain compact, biologically stable fuels.

2 Basic principles

Pertinent literature includes a number of reports [1, 2] dealing with the design of facilities for producing either pelletized fuel with high mechanical and thermal stability from residual waste or fuel retaining the high-caloric fraction (HCF) of waste processed at mechanical-biological and mechanical-physical waste treatment plants.

For cement producers, et al, with constant exposure to pricing pressures, having access to a high-quality SRF opens up some attractive economical alternatives. The main financial advantage lies in the substitution of soft or hard coal of domestic origin. With regard to imported hard coal, however, the cost would remain extensively equal. Also, rudimentary processing of the kind employed at a typical mechanical-biological waste treatment (MBWT) plant is more economical than comparatively extensive conditioning by means of drying and compounding.

On the other hand, experience shows that, due to certain, specific preparation steps and to differences in process structuring, the as-delivered SRF is not always free of non-biodegradable contaminants, metals of some description or inert substances. Its residual moisture content, too, can fluctuate and have a negative impact both on the burner flame and, consequently, on the performance of the burner control system.

3 Process description

A simple technology for reducing the contaminant content of any and all delivered and received fractions now enables online preparation upstream of the kiln, including kiln-control stabilization.

Arriving by walking-floor trailer, the SRF is fed continuously to a receiving and dosing station, where the alternative fuel is decompacted. By way of a conveying and weighing system, the SRF is pneumatically transferred to the SI-TRO-ZER unit. There, the continuous flow of SRF material is freed of contaminants and simultaneously dried and reduced to the desired particle size in an ascending stream of hot exhaust air from the clinker cooler.

Then, the entrained air from pneumatic handling is expelled from the ready-processed SRF, which is then blown into the kiln’s burners (Figure 1). The extracted contaminants are collected separately and can be returned to the recycling company, for example.

SI-TRO-ZER functional characteristics

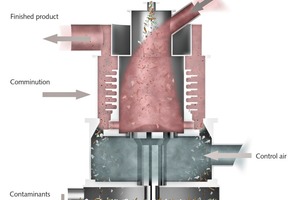

The alternative fuel (SRF) is pneumatically or mechanically injected onto the rotating dispenser below the rotor. The flow of material accelerates both radially and tangentially as it sprays out in all directions from the dispenser. When the material reaches the impact ring, the ensuing collision disagglomerates it. In the sorting zone, the drying and control airstream separates the light material from the contaminants.

The light material is blown up into the shredding zone, where its size is further reduced with the aid of high circumferential velocity and, at the same time, dried to the targeted residual moisture level. Separated out by force of gravity, the contaminants drop towards the bottom of the sorting zone, where they collect and are removed via conveyor. Finally, a cyclone separator removes the finished, post-dried SRF from the recirculating clinker-cooler air for pneumatic injection into the kiln (Figure 2).

Wear & tear

Since the contaminants are kept out of the shredding zone, there is little wear and tear on the cutting blades. Likewise, the other conveying sections, both pneumatic and aerial, are subject to much less frictional wear. The chopping elements and impact plates are readily accessible for inspection and, if necessary, replacement through the lateral service openings, with no need to disassemble the unit.

Technical data

Dimensions:

Length: 3600 mm

Width: 3200 mm

Height: 3370 mm

Rotor diameter: 1500 mm

Weight: 17 t

Performance data:

Power requirement: 110 kW

Throughput: 6 t/h

Speed: infinitely variable

Summary

Voges Maschinenbau GmbH has more than 30 years’ experience in the handling and processing of SRF in the cement industry. The company’s proprietary processing technology enables the drying, sorting and shredding of waste in a single-stage process. Voges’ prototype SI-TRO-ZER unit is in successful, trouble-free, non-stop operation at the Dyckerhoff cement plant in Geseke/Germany (Figure 3).

The essential characteristics of this patent-pending technology are:

variable drying for achievement of < 10 % residual moisture

sorting and expulsion of contaminants, metals, minerals, etc.

entrained-flow comminution

infinitely variable throughput as a burner-control function

easy maintenance

minimal wear & tear and resultant costs thanks to absence of force-induced comminution with screen baskets

//www.voges-maschinenbau.de" target="_blank" >www.voges-maschinenbau.de:www.voges-maschinenbau.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.