Phase quantification of Indian industrial clinkers containing minor oxides

Minor oxides in kiln feed influence the kinetics of clinker formation, mineralogical composition, polymorphism of clinker phases and other properties of clinker. Investigations on the phase quantification of industrial clinker samples containing minor oxides are presented in this paper. A comparative evaluation of different methods for quantification of clinker mineral phases was made. Typical industrial clinker samples were subjected to XRD analysis for qualitative and quantitative mineralogy. Distribution of minor oxides in the clinker phases was investigated by SEM-EDXA. The Bogue and Taylor methods were employed to calculate the phase contents of clinker samples and the values were compared with the results obtained from experimental technique.

1 Introduction

Increasing concern regarding Green House Gas (GHG) emissions combined with economical benefits lead the cement manufacturing sector, one of the energy intense sectors, to use various industrial waste materials and by-products. Assimilation of unconventional minor oxides, from different industrial waste streams, in clinker phases significantly affects the properties of cement. Presence of low concentrations of certain elements may influence the clinker phases to a large extent resulting in unforeseeable changes in the performance characteristics of cement.

Chemical composition of...

1 Introduction

Increasing concern regarding Green House Gas (GHG) emissions combined with economical benefits lead the cement manufacturing sector, one of the energy intense sectors, to use various industrial waste materials and by-products. Assimilation of unconventional minor oxides, from different industrial waste streams, in clinker phases significantly affects the properties of cement. Presence of low concentrations of certain elements may influence the clinker phases to a large extent resulting in unforeseeable changes in the performance characteristics of cement.

Chemical composition of raw materials is one of the main parameters having effect on all distinctive features of clinker formation like temperature of appearance of liquid phase, melt viscosity and surface tension, nucleation environment and crystal growth of clinker phases and their phase relationships. Presence of impurities or minor components in raw materials is one of the constantly varying parameters. These impurities affect all the features of clinkerization mentioned above to varying extents and finally get incorporated in the crystal lattice of four major phases and may also settle as extra components (like alkali sulphate, double salts etc.) to some extent depending upon overall chemistry of the raw mix. Therefore, pure compounds (C3S, C2S, C3A and C4AF) are mere matrices with a large number of crystallo-chemical sites in the lattice for impurity atoms. It is also important to note that these impurities are one of the major factors for stabilization of various crystalline forms (polymorphism) of clinker phases. A number of studies conducted in the past have established the role of MgO, SO3, Na2O, K2O etc on the stabilisation of polymorphic forms of alite and belite [1-4]. These minor oxides, present in the lattices of clinker phases as impurities, cause the changes in the chemical composition and in the crystal structure of the phases [5, 6]. Further, there is much deviation in the calculated and actual amount of clinker phases due to the presence of impurities in the crystal lattices. The general procedure to calculate the amount of clinker phases is due to Bogue [7] and it was found that these values deviate greatly from the values obtained from XRD and other techniques [8].

X-ray diffractometry has been proved a promising tool to identify and quantify the crystalline phases and can be used as on-line analysis technique for quality control in cement plants. Overlap of the principal peaks of clinker phases poses complications for the direct quantitative phase analysis by XRD pattern and demands additional calibration programs. The Rietveld refinement method [9,10] provides a way to estimate the phases even when the XRD pattern contains a mixture of phases with overlapping lines [11]. This method takes the crystal data, refines the XRD pattern by least-square fitting and provides the refined values of the parameters along with the quantification of the phases.

As the presence of impurities in the crystal lattice of clinker phases affects the clinker phase formations and their weight fractions, the presence and distribution of these impurities has to be studied to calculate the actual amount of clinker phases. Scanning electron microscopy (SEM) with Energy Dispersive X-ray Analysis (EDXA) [12] system can be used for in depth examination of the microstructure and also for the elaborated study of the distribution of minor oxides.

Substantial research work has been done on XRD, the Bogue and Taylor methods for clinker phase quantification. However, there is not much data available on comparative evaluation of the three methods for quantification of Indian industrial clinker samples. In the present work, different Indian industrial clinker samples were studied using XRD and SEM. The amount of clinker phases were calculated by the Bogue method, based on chemical data. The Rietveld refinement method was applied on the XRD data for the quantification of clinker phases and the values were compared with the results from Bogue calculations. Then these samples were studied under SEM with EDXA to find the distribution of minor oxides in the clinker phases. The Taylor method [13, 14], in which the presence of impurities in the pure clinker phases was taken into account, was used to estimate the amount of clinker phases and the values from these three different methods are compared. Finally the role of the XRD-Rietveld method and SEM-EDXA in the characterization of clinker phases is discussed.

2 Experimentation

Typical samples of clinker for the experimentation were collected from different cement plants across India and were evaluated for chemical composition and mineralogy using standard chemical analytical methods and instrumental techniques.

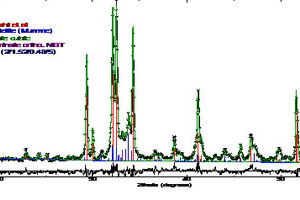

Samples for the XRD studies were ground, passed through a 45 micron sieve and care was taken to eliminate particle size and preferred orientation effects. The sample holder was continuously rotated to present the smooth surface of the sample to the incoming X-ray beam. Powder X-ray diffraction data was recorded using Rigaku D/Max 2200 V/PC instrument (Cu-Kα radiation). Samples were scanned for 4 hours from 50 to 650 with a step size of 0.020 to obtain high quality data for Rietveld refinement. The optic system of the instrument includes 1 deg Div slit, 2 mm Div. H. L. Slit, 0.3 mm Rec. Slit. and soller slits. The X-ray tube was operated at 1.2 KW (40 KV and 30mA) power for recording the pattern.

Rietveld refinement of the patterns was carried out using the MDI RIQAS (V 4.5) program. The crystal data for the Rietveld method contains monoclinic C3S (space group: C1m1(8)), monoclinic Belite (space group: p121/c1(14)), cubic C3A (space group: pa-3 (205)), orthorhombic C3A (space group: pbca (61)) and orthorhombic C4AF (space group: 1ma2 (46)). The parameters refined include scale factors, lattice parameters, profile shape parameters, specimen displacement and background coefficients. The pseudo-Voigt profile was used to model the background. Atomic coordinates, thermal parameters were not refined due to the complexity of crystal structures of the clinker phases. Correction for preferred orientation was not included in the refinement.

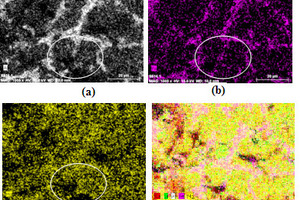

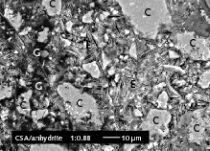

SEM studies were conducted by using JEOL JSM-1510LV and EDAX studies were carried out using Bruker Quantax. Nodules of clinker samples were ground to obtain a flat surface to face the electron beam. X-ray elemental maps were recorded at a HT of 15 KV and a working distance of 10 mm.

3 Results and discussion

The chemical analysis of clinker samples is given in Table 1. Weight percentage of oxides was determined using XRF and free lime was determined by wet chemical methods.

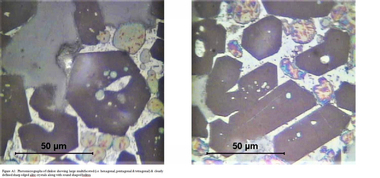

Potential clinker phase compositions were calculated using the Bogue method. Corrections were made in CaO for free lime and SO3. The amount of clinker phases were also estimated by the XRD technique. Alite, C2S, C3A and C4AF were commonly found in all the samples. The Alite phase was present in monoclinic structure (M1+M3), C2S was present as β-polymorph (belite), C3A was found as cubic or orthorhombic or combination of the two and C4AF was in orthorhombic structure. Periclase and CaO were also found in some samples, but in very small amounts. Preferred orientation effects of clinker phases were not observed.

Figure 1 shows the Rietveld refined pattern of one of the clinker samples. Rwp values of the fitness for all the samples were found to be less than 8.5, validating the refinement strategy. The parameters that define the quality of the fitting are given in Table 2.

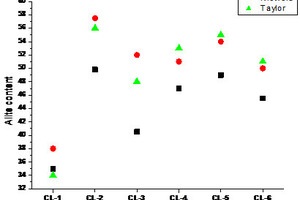

The amounts of clinker phases calculated by the Bogue method, the Taylor method and also estimated by the XRD (Rietveld) methods are given in Table 3. Bogue values are found to bdeviate greatly from the XRD values. This can be attributed to the presence of minor oxides in the major clinker phases, particularly in C3S. The Bogue method does not consider the presence of minor oxides in the major clinker phases and assumes the thermal equilibrium conditions, which cannot be realised in practice.

X-ray dot maps of one of the clinker samples are shown in Figure 2. The presence of minor oxides such as MgO, Al203 and Fe2O3 in C3S can be observed in the figure. The amount of MgO is more than the amount of Al2O3 or Fe2O3 in C3S (circles). It is well known that MgO plays an important role in the stabilization of alite and also that the alite content increases with the MgO in clinker up to a certain limit [15].

The Taylor method, which considers the presence of impurities in the clinker phases, was used to calculate the amount of the clinker phases. The saturation value of Fe2O3 in alite was taken as 1.1%. The method entails solving of four simultaneous equations to find the amount of four clinker phases.

Figure 3 shows the comparative evaluation of the values of alite obtained from three different methods. The amount of alite obtained from the Rietveld and Taylor methods are close to each other (except in sample no. CL-1) while the values from the Bogue method deviate greatly from the experimental (XRD/Rietveld) values.

Although the equations used in the Taylor method are valid for most of the conventional clinkers, they require modifications when the unconventional materials are used in the manufacture of cement as has become normal practice in the Indian cement industry.

4 Conclusions

Indian industrial clinkers have shown phase quantities that deviated greatly from the calculated Bogue values. SEM/EDXA confirmed the presence of impurities in the main clinker phases. The Taylor method, which considers the impurities present in the phases, produced much closer values to the experimental results. The XRD/Rietveld method coupled with SEM/EDXA can provide the information regarding purity of the clinker phases and distribution of minor oxides in the major clinker phases to enable use/modification of the Taylor equations to calculate the amount of the clinker phases. Further, more correlations between the industrial clinker phases and the mechanical properties of the resultant cement are required in order to effectively utilize these experimental techniques for the cement industry.

Acknowledgement

The work reported in this paper forms a part of research and development work completed in NCB. The authors are thankful to Director General, NCB for allowing publication of this paper.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.