Influence of the mineralogy and

microstructure of clinker on its grindability – an Indian perspective

This article aims to determine the relationship between the chemico-mineralogical and microstructural parameters of clinker that fundamentally influence its grindability. The study investigated the grindability and microstructure of various commercial clinkers with different chemico-mineralogical compositions that had been produced around the country. The author has attempted to develop a mathematical relationship (where this exists) between the Bond work index and the chemico-mineralogical and microstructural parameters of the clinkers produced in India.

1 Introduction

Portland cement clinker is a combination of minerals formed during the burning process and solidified from the liquid phase. One of the important properties, which is of significant industrial relevance in terms of energy and productivity, is the resistance of the clinker to mechanical loads i.e. its grindability. It is well known that the resistance to mechanical stress and the grindability of clinker has a considerable influence on the operation of grinding equipment and on the energy required for grinding. This affects the particle size distribution and the quality of the...

1 Introduction

Portland cement clinker is a combination of minerals formed during the burning process and solidified from the liquid phase. One of the important properties, which is of significant industrial relevance in terms of energy and productivity, is the resistance of the clinker to mechanical loads i.e. its grindability. It is well known that the resistance to mechanical stress and the grindability of clinker has a considerable influence on the operation of grinding equipment and on the energy required for grinding. This affects the particle size distribution and the quality of the cement produced.

2 Experimental

Representative samples were collected from different units in order to study the effect of variations in the mineralogy and microstructure of the clinker. The samples were then characterized in terms of their:

granulometry

Bond work index

Bogue composition, based on chemical analysis by XRF

actual mineralogical composition using XRD

mineralogical composition, grain size, etc. using an optical microscope to evaluate their effect on the grindability, if any

trace metal analysis by ICP-OES

2.1 Bond work index

The standard feed for carrying out the Bond test is prepared by crushing the as-received samples using a jaw crusher so that it passes through a 3.35 mm sieve. 700 cc of the resulting product is weighed and placed in the Bond index mill and ground at 250 % circulating load. The ball mill work index (kWh/t) is calculated from the equation:

(1)

Where P1 is the test sieve size, Gbp is net grams of average product size generated per revolution, P80 is size of the product corresponding to 80 % cumulative passing and F80 is the size of the feed corresponding to 80 % cumulative passing.

Table 1 shows the work indices for the clinker samples examined together with their actual mineralogical composition and microscopical features evaluated using XRD and OM respectively and the potential phase composition derived by the Bogue method from chemical analysis of the clinker samples by XRF from the respective units. The Bond work index for all the clinker samples was found to be in the range of 10.30 – 15.55 kWh/t indicating the wide variation in their grinding behaviour. The effects of various chemical and microstructural/mineralogical parameters on its grindability are summarized below:

A. Effect of chemical composition

on clinker grindability

The chemical composition of clinker was provided by the respective units using their standalone XRF and the potential phase compositions were calculated using the Bogue equation. The chemical parameters and corresponding moduli along with the grindability data are tabulated in Table 1. The main parameters, i.e. LSF, AM, SM, the ratio of Bogue-derived phases, i.e. C3S/C2S, (C3S+C2S)/(C3A+C4AF) and percentage liquid content are plotted against the Bond work index of the clinker.

Using mathematical regression analysis, no correlation was observed between the Bogue-derived LSF, SM, AM, C3S, C3A, C4AF and liquid contents. The relationships between the chemical constituents analyzed by XRF, i.e. CaO, SiO2, Al2O3, Fe2O3, MgO, K2O and Na2O, and the Bond work index were analyzed mathematically by regression analysis and no correlation was found.

An increase in SO3 content makes the clinker harder to grind, as is indicated by regression analysis. The relationship between the Bogue-derived phase C2S and the Bond work index shows that the work index increases with increasing C2S content. The correlation between the Bond work index and percentage free lime content indicates that a higher free lime content in the clinker gives a higher work index. An increase in periclase (by XRD) makes clinker harder to grind, as is shown in the regression analysis graph between the two parameters. No correlation was observed between the Bogue-derived phases C3S/C2S and (C3S+C2S)/(C3A + C4 AF).

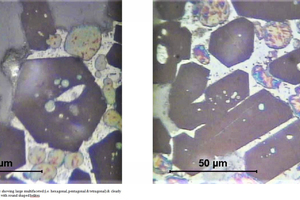

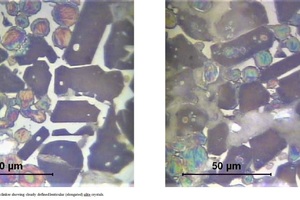

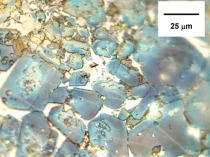

B. Effect of microstructure on clinker grindability

The grindability of clinker depends predominantly on the structure and morphology of the clinker. Most of the available literature on the relationship between clinker microstructure and grindability agrees that the primary influential factors are the alite and belite crystal size and content. Specifically, smaller crystals and more alite (less belite) result in clinker that is easier to grind. Numerous equations are found in the literature for predicting clinker grindability based on its microstructure. Although the equations vary somewhat, the relationship to alite and belite content and size previously described is consistent.

The alite size is more or less constant if the flame configuration and heating rate remain constant. However, the belite sizes vary considerably depending upon rotational speed of the kiln and the retention time of material in the burning zone. In the cases where the belite grain size is small they are mostly found to occur as tightly bound clusters masked with dense interstitial phase. The belite grains that occur in clusters make the clinker difficult to grind.

The aim of this study is to determine the microstructural properties of clinker that have a fundamental influence on the grindability. The grindability and microstructure of commercial clinkers with different chemico-mineralogical compositions and produced with different technologies were studied during the research. The tests were made under reflected light using a mineralogical microscope. It was found that the grindability of a clinker of a given mineral composition is considerably influenced by the microstructure of the clinker and that the evolution of the microstructure depends primarily on technology parameters. The test results relating to this are presented below.

3 Macroscopic properties

Clinker nodules were received from the units for microscopic study. In almost all the clinkers the surface was found have a dark glittering colour. Most of the nodules consisted of a single fraction. A very small percentage of finer fractions (dust) was observed in the samples received.

3.1 Methodology

All the clinker was crushed to a size of 3-5 mm to obtain representative samples after coning and quartering. These crushed fractions were chosen for microscopic study. The samples were then subjected to vacuum impregnation to fill up the pores. The impregnated moulding was ground initially with abrasive diamond paper to achieve a smooth surface. Further fine grinding was then carried out with 240, 320, 600 and 800 mesh carbimet paper. The polished samples were finally etched with HF vapour for the microstructural study. The grain size distribution and modal analysis were evaluated using an image analysis system.

From the results in Table 1 it can be seen that the average alite crystal size in all the samples was moderate (15-30 µm).The alite size indicated that rapid heating had taken place in all the pyro-processing sections of the units. In the case of belite the crystal size was smaller (< 15 µm) except for the clinker from unit 6 and unit 25. Table 2 shows the distribution of alite and belite crystals in the different size fractions.

3.2 Mathematical correlation between Bond work index and microstructural properties as derived by optical microscopy

An attempt was made to determine the mathematical correlations between the Bond work index and the microstructural properties of the clinker, i.e. alite size, belite size, content of alite, content of belite and percentage of interstitial matter. Regression analysis revealed that there is fair correlation between the Bond work index and the belite size. The belite size is inversely proportional to the index, i.e. a higher belite grain size of the clinker indicates a lower Bond work index .There is little correlation between the Bond work index and alite size, alite content, belite content and interstitial matter determined by OM.

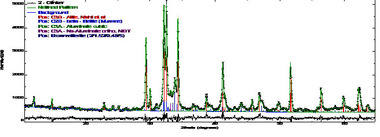

C. Effect of clinker mineralogy on grindability index

The XRD patterns of all the clinker samples were generated under identical conditions. The free lime, periclase and sodium sulfate structures were also loaded during Rietveld refinement along with the normal clinker phases. The diffraction pattern was optimized through a calculation procedure in order to obtain the best possible fit to the experimental diffraction pattern. The clinker mineral phases were quantified and measured for each sample using the Rietveld refinement and Topas software. A sum-mary of the results obtained is given in Table 1.

The C3S in the clinker samples was found to vary in the range of 48.51 to 59.95 %. The highest value of C3S was found in Unit 16 clinker (59.95 %) while the lowest was observed in Unit 24 clinker (48.51 %). The C2S varied from 14.42 % [Unit 16] to 30.76 % [Unit 24]. The variation in C3A and C4AF was estimated to be 1.43 % [Unit 13] to 16.26 % [Unit 24] and 9.40 % [Unit 24] to 18.37 % [Unit 20] respectively. Free lime, periclase and sodium sulfate ranged from 0.00 % [Unit 4, Unit 16 and Unit 6] to 2.08 % [Unit 2], 0.03 % [Unit 20] to 2.32 % [Unit 13] and 0.00 % [Unit 16] to 0.58 % [Unit 5] respectively. A fair correlation was observed between the XRD-C3S and the Bond work index (BI) of the clinker samples. Little correlation was observed between the C3A, C4AF, CaO, MgO and Na2SO4 obtained by XRD and the Bond work index values.

The following conclusions can be drawn from the above XRD analysis.

1. The highest value of C3S is 59.95 %

was found in Unit 16

2. The lowest C3S was observed in Unit 24

(48.51 %) clinker

3. The maximum free lime of 2.08 % was found

in Unit 2 clinker

4. The maximum MgO of 2.32 % was found

in the Unit 13 sample

5. The highest level of Na2SO4 (0.58 %)

was detected in Unit 5 clinker

4 Mathematical correlation between mineralogical

properties and grindability

Based on regression analysis, no strong correlation was observed between any of the mineralogical parameters and the clinker grindability (work) index. However, some correlation was observed between alite, belite, periclase, free lime and Na2SO4 (see Table 4).

D. Effect of trace metals on the grindability index

Trace metals in clinker come from both the primary and secondary raw materials and the fuels used. The effect of the trace metals is to a large extent dependent upon:

the type of trace element

its concentrations in the kiln feed and fuel

its volatility at high temperature and the degree of retention in clinker

A review of the literature suggests that the grindability of clinker containing transition metal oxides could be classified in order of decreasing clinker grindability as follows:

MnO, Cr2O3, Ni2O3, ZrO2, CuO, Co2O3, V2O5, MoO3, TiO2, ZnO (Tsivilis and Kakali, 1997)

An attempt was therefore made to correlate the trace metals with the Bond work index for all the clinker samples. The clinker samples were subjected to trace metal analysis using Leeman’s inductively coupled plasma – optical emission spectroscopy (ICP-OES). The results obtained are given in Table 3.

Correlation studies on 27 clinker samples revealed that no strong relationship was observed by mathematical regression analysis. Some correlation was observed between Mn and the Bond work index. The clinker becomes harder to grind with increasing Mn content.

5 Conclusion

The grindability of clinker is mainly affected by the crystal size, the percentage of the silicate phases and their distribution. The clustering form of the belite phases and the porosity of the clinker are also important parameters related to grindability.

From the above discussion it appears that although no strong mathematical correlation was found by regression analysis, certain chemical, mineralogical/microstructural parameters do influence the clinker grindability. An increasing or decreasing trend of particular parameters can influence the clinker grindability either positively or negatively. There is an inversely proportional relationship between the Bond work index and the alite content of the clinker, where clinker hardness decreases with increasing alite content. No mathematical correlation was found between clinker granulometry and its grindability. Controlling the content of alite and belite phases and the optimum chemical composition of clinker are essential considerations for an economical grinding process.

Systematic study of the clinker microstructure helps to evaluate clinker grindability. A good microstructure makes the clinker easier to grind. The alite size is a measure of the kiln temperature rise between 1200-1450oC where C2S combines with CaO to form C3S. Rapid heating is desirable and is indicated by an alite size of 15-20 µm, while slow heating produces alite of 40-60 µm or above. The belite size reflects the retention time in the burning zone above 1400oC. A long retention time results in an average crystal length of 25-40 µm, while a short retention time yields 5-10 µm.

Certain secondary and trace elements introduced with fuels and with waste materials used as alternative materials also have a positive effect on the structure and hardness of clinker phases and thus also on clinker grindability.

//www.dalmiacement.com" target="_blank" >www.dalmiacement.com:www.dalmiacement.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.