Perfect dosing – precise and reproducible

For people operating industrial production facilities in the bulk solids industry, steadily escalating product-characteristic requirements and rising quality standards make it challenging to handle very small quantities of pigments and other additives. Since such additives often exert a crucial influence on the multifunctional characteristics of the end products, any deviation in dosage can have major impacts. Therefore it is particularly important for the investor/operator to choose and install reliable systems. This article presents a potential system approach with which to get and keep the matter under close control, with maximum accuracy and flexibility.

1 Introduction

Across the bulk solids processing industry, the automatic dosing of small and very small quantities still presents a challenge, especially with regard to the precision and reproducibility of completed production orders. Manual dosing can lower both productivity and efficiency while increasing the risk of human error.

Dosing, weighing and feeding are routine tasks in the bulk solids processing industry. Today’s plants are designed for the completely automated addition of major, intermediate and minor constituents and their further processing. However, many very small-quantity...

1 Introduction

Across the bulk solids processing industry, the automatic dosing of small and very small quantities still presents a challenge, especially with regard to the precision and reproducibility of completed production orders. Manual dosing can lower both productivity and efficiency while increasing the risk of human error.

Dosing, weighing and feeding are routine tasks in the bulk solids processing industry. Today’s plants are designed for the completely automated addition of major, intermediate and minor constituents and their further processing. However, many very small-quantity constituents still tend to be weighed by hand for feeding into the downstream processes. There are many possible reasons for this: Perhaps the plant concept included no automatic addition equipment for lack of space, or a limited investment budget precluded the relevant expenditure, or no suitable dosing system could be located. Whatever the reason, the result is not only inefficient, but also carries a risk of human error, and it takes accordingly more effort to achieve reproducibility and consistent batch tracking.

2 Determinative: solution expertise

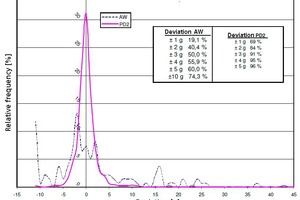

Apart from manual dosing, the two main conventional dosing options for minor constituents are proportioning screws and vibratory feeders in conjunction with appropriately designed scales. These options are time-tested and relatively simple, but of limited scope and often rather slow (Figure 2 and Figure 3).

Standard-type, commercially available systems often prove inadequate for certain, special application problems. Now, that very problem has triggered the development of a fine-tuned system intended to meet the following set of requirements:

precise, dust-free dosing of multiple minor and trace constituents

high-accuracy, close-tolerance gravimetric dosing

dosing of sundry dry powders, slow-flowing products and granulated material with grain sizes up to approx. 5 mm

flexible dosing range (from single-digit gram range to double-digit kilogram range)

With deference to the increasingly complex challenges posed by today’s technical solutions, a modular, fully automatic micro-component dosing system for operation both online and offline has now become available.

Thanks to many long years of experience in the development, engineering and design of such equipment, in combination with intensive interdisciplinary know-how and application experience, m-tec was able to hone and refine this dosing system.

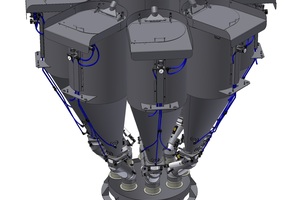

The Powerdos dosing principle emulates the natural process of manual dosing in the laboratory. For example, in order to increase the flow of powder, you simply tap the spatula with your finger a little more intensively. This tells the Powerdos system to increase the oscillation frequency of the dosing valve and to raise the amplitude in order to accelerate the dosing rate (Figure 4).

The raw materials are dosed via a vibrating rubber valve in an inclined rubber tube, at the end of which an orifice widens or narrows, depending on the intensity of actuation. The flow of material is controlled by an advanced type of control module. The system doses the material into a mobile or stationary hopper scale, all according to the specified formulation.

Figure 5 compares the dosing tolerances of a conventional screw feeder weighing system “AW” with those of a Powerdos system “PD2”.

The Powerdos system enables mass-flow and dosing rates across the very wide range of 0.5 – 500 g/s.

3 Automatic dosing of minor constituents

in plant engineering and construction

3.1 Online system

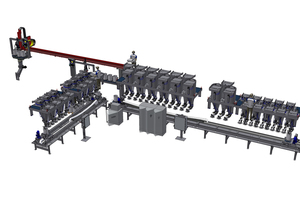

If the main focus is on residue-free discharge, the fully-automated inline minor-constituent series-dosing system with hopper scale and automatic product conveyance to the discharger is the recommended solution (Figure 6). The system doses the proper amounts of specified constituents into the mobile hopper scale, which then moves on to the discharger at the end of the line, where the hopper is emptied and cleaned from all residue. The now empty container is immediately ready for the next dosing step.

The dosing system can be equipped with an optional active dust removal system for dedusting. The individual dosing points, feed silos and weighing vessels can be vacuumed out after emptying.

Different sizes of raw material silos are available. The feedstock can be taken from sacks or big bags. The system offers multiple advantages:

system accuracy up to +/- 2g for free-flowing products

guaranteed batch tracking and reproducibility

dosable range between 2 g and 60 000 g per batch

3.2 Offline system

If, however, flexibility is what counts most, an offline version of the fully-automated minor-constituent series-dosing system with mobile hopper scale is recommended (Figure 7).

In this configuration, the dosing vessel itself can either be removed for forwarding the batch or fitted with some kind of lining, e.g., a plastic bag.

The offline system offers several advantages against the online version:

batches can be pre-produced

several mixing systems can be fed at the same time

3.3 Compact system

The compact system comprises a fully-automated minor-constituent dosing system with hopper scale and optional pneumatic product transport to the downstream process (Figure 8).

The dosing valve feeds into the hopper scale as prescribed by the formulation. The scale, in turn, empties either directly into the downstream process (e.g., batch mixer) or into a pneumatic conveying unit. The main advantages of this version are:

system accuracies up to +/- 5 g achievable for adequately fluent grains and powder

guaranteed batch tracking and reproducibility

dosing range of 50 g to 210000 g per batch

easy retrofitability

4 Outlook

m-tec is a successful German company offering abundant know-how acquired in numerous branches of industry and diverse countries and spanning 40 years of experience in bulk solids technology. Each individual system is tailored to the customer’s own technical and commercial requirements.

This enables owner-operators to provide their customers with products of consistently high quality, for now and in the future.

//www.m-tec.com" target="_blank" >www.m-tec.com:www.m-tec.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.