Control additives influence the filler recipe

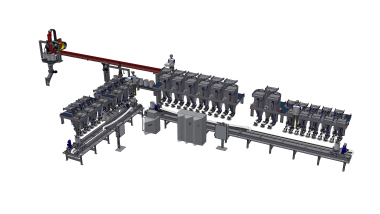

Summary: Control additives and small components are decisive parameters for the high-quality and efficient production of fillers and other construction chemical products. AZO has developed a concept for Pufas, in which all components required for the recipe are integrated, starting from the product feed from sacks to big bags and containers, a dosing and weighing unit and the precise weighing of batches, with verification of the recipe composition. With a pressure pulse conveying system the precisely weighed batches are then conveyed over a distance of 70 m into the bulk quantity mixing system. The automatic feeding system provides inventory transparency, data regarding the quantities produced and a quick ROI (Return on Investment).

The Pufas Company in Hannoversch Münden/Germany is a very innovative owner managed medium-sized business. Pufas has a core business alongside painters‘ filling that also includes adhesives, fixings and undercoats as well as a complete renovation programme in its product range. Control additives and small components are decisive parameters for high-quality and efficient production, since they essentially control the recipe of fillers. A high dosing precision is indispensable for a clean recipe composition. According to Gerhard Jordan, managing director and...

The Pufas Company in Hannoversch Münden/Germany is a very innovative owner managed medium-sized business. Pufas has a core business alongside painters‘ filling that also includes adhesives, fixings and undercoats as well as a complete renovation programme in its product range. Control additives and small components are decisive parameters for high-quality and efficient production, since they essentially control the recipe of fillers. A high dosing precision is indispensable for a clean recipe composition. According to Gerhard Jordan, managing director and sole proprietor, Pufas places very high value on cleanliness and the best quality. They therefore went into the control additives and small component automation market seeking a supplier who was able to guarantee a closed system and very high formula composition precision in the gram range, including verification. AZO was able to offer a suitable solution. It essentially consists of a flexible product intake for sacks, big bags and containers and a dosing and weighing system for the precise weighing of batches, which are then conveyed to the mixing process (Fig. 1).

Raw materials, delivered in sacks, are supplied dust-free to the pneumatic mixer feeding system via a feeding station. Aspiration starts automatically when the hopper lid opens (Fig. 2). The operator puts the sack onto the work table, opens it and discharges it with low dust levels into the closed system. The filter dust produced during suction falls back into the hopper through the assembled filter. The hopper is equipped with combined vibration dosing screw conveying and permits high-precision dosing into the pneumatic conveying line. The screws gear drive 10:1 with reversible poles makes it possible to greatly reduce dosing output during fine dosing, giving high dosing and weighing precision.

A total of two big bag discharge stations are provided for emptying big bags into the closed system (Fig. 3). The big bags are brought to the discharge station by transport vehicles. Then the big bag is docked onto the outlet using a special connection system. As soon as docking is complete, the operator opens the clasp cord and the big bag is emptied into the downstream buffer hopper with a volume of 1500 l. These buffer hoppers are also equipped with vibration bottoms and reversible pole dosing screws. The buffer hoppers are simultaneously used as a hold supply and the operator is notified immediately by a low level indicator when they have to be filled.

Special blends are produced by a separate mixing process, which are then filled into the BATCHTAINER® with 1000 l capacity changeover containers (Fig. 4). These BATCHTAINERs®, equipped with a butterfly valve, are then put onto the container discharge station and docked on in a dust-free manner using a docking sleeve. Here there is also the possibility of emptying the changeover containers into small buffer containers, which leaves enough time to put a new BATCHTAINER® into position for quick recipe change. These buffer containers are also equipped with a vibration bottom discharge in combination with dosing screws. The BATCHTAINERs® permit quick formula changing and maximum flexibility.

The various components from the hoppers, big bag discharge stations and BATCHTAINER® filling stations, are conveyed into the conveyor scales and simultaneously weighed precisely in accordance with the formula. All components are linked via a conveying line with the conveyor scale (Fig. 5). The blower unit creates the vacuum after the system starts. Product feeder or dosing screws start. The conveyed goods are fed into the conveying line and sucked into the scale. The conveyor scale is also used as a receiver and is equipped with compressed air cleaned filters for air product separation. The frequency-controlled dosing device is switched from coarse to fine dosing before the set target value is reached. Product loading decreases. For any components the conveying line is then emptied by suction and the residual incorporated into the weighing process as a run-on. This makes throughput somewhat lower than with the multiple-pipe system. The various run-on quantities are taken into account by the process control system. In accordance with the recipe, all components are then available in the conveyor scale within narrow tolerance limits ± 100 g for further transport into the bulk quantity mixing system.

The precisely weighed batches are then conveyed by a pressure pulse conveying system into the bulk quantity mixing system over a 70 m conveying distance with a conveying velocity of 8 m/s. The precisely weighed batch is emptied into the pressure vessel. The pressure pulse conveying system works continuously with pressure pulses. This means that an air cushion is pushed into the conveying line by a special conveying air supply (Laval nozzle) between each product plug. A receiver equipped with a scale is located at the end of the conveying system. This receiver checks whether all the components sent from the conveyor scale have in fact arrived in the bulk quantity area. As soon as this check has been performed the entire batch is fed into the bulk quantity mixing process. A process control system with process visu-alisation is used to control and monitor the entire dosing, conveying and weighing process. It is possible to document all recipes with precision in accordance with the Pufas quality philosophy. The closed systems ensure clean production, prevent product displacements and material losses and reduce cleaning requirements. The automatic feeding system for the minor ingredients which influence the recipe provides inventory transparency, data regarding the quantities produced and a quick ROI (Return on Investment).

AZO has a stand at the European Coatings Show 2011, Hall/Stand 6-331

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.