Full modular control system for gravimetric dosing applications

The efficient implementation of accurate gravimetric dosing system for material feeding or blending in cement plants require both, a reliable mechanical platform and a robust, precise and ergonomic control system. The new ODM-GravitAS control system is a modular and open architecture for a wide range of gravimetric dosing devices. This article introduces the novel control strategy for its usage with the innovative tubular weighing system ODM-WeighTUBE® for the dosing of alternative fuels and other bulk materials.

1 Introduction

The integration of reliable and accurate gravimetric dosing systems into conveying lines for bulk materials, e.g. alternative fuels, can be considered as an important engineering stage in order to build up efficient and economically feasible material feeding or blending plants. In this context several different technologies for the metering of bulk material, such as belt weigh feeders or differential dosing units, have been applied in the past in the cement industry. The decision for a particular dosing technology depends mainly on the individual specifications of the bulk...

1 Introduction

The integration of reliable and accurate gravimetric dosing systems into conveying lines for bulk materials, e.g. alternative fuels, can be considered as an important engineering stage in order to build up efficient and economically feasible material feeding or blending plants. In this context several different technologies for the metering of bulk material, such as belt weigh feeders or differential dosing units, have been applied in the past in the cement industry. The decision for a particular dosing technology depends mainly on the individual specifications of the bulk material and the corresponding process requirements.

In most cases different types of dosing systems require the implementation of particular control system architectures, which often follow a closed proprietary system design philosophy. Thus, it is common practice, that there are numerous different metering and dosing controllers and their corresponding electrical equipment (load cell couplers, HMI, etc.) in operation within a single cement plant. This leads to a scenario, where the personnel in the plant has to deal with the unavoidable drawbacks of closed control system architectures, such as a high demand for specialized product training for the service technicians, the necessity of holding spare parts for different controller types and possible problems with system incompatibilities.

During the last years, Di Matteo developed a full modular hardware and software concept for the realization of gravimetric dosing controllers, which is only based on off-the-shelf products from widely accepted vendors of automation products. This ODM-GravitAS control system was initially developed for its usage with the revolutionary and award-winning ODM-WeighTUBE®, a novel tubular weigh feeder designed in particular for problematic secondary fuels and polyethylene granulate material (see also [1]). Since the first installation of the new feeding technology in 2010, round about 50 units of the ODM-WeighTUBE® are integrated worldwide and the applicability of the novel weighing system was expanded to conventional bulk materials, such as fly ash, iron core, raw meal, clinker, etc.

Figure 1 shows the different types of the ODM-WeighTUBE® RWS, which are meanwhile produced in series at the German production facilities of Di Matteo and well established within the cement industry for the trouble-free dosing of alternative fuels for desired mass flows between 0.3 and 20 t/h.

This article provides an overview of the modular hard- and software concept of ODM-GravitAS for its usage with the WeighTUBE® dosing system, where section 2 describes the mechanical platform and the main algorithmic entities of the GravitAS system.

One main innovation of the GravitAS control philosophy is the ability of the controller to tune itself to varying material properties, which is explained in section 3. The open and modular architecture of the controller is introduced in section 4, where one major advantage is the possibility of using the same tailor-made control philosophy for different dosing platforms, as shown in section 5. Finally section 6 concludes the whole article.

2 ODM-WeighTUBE® and GravitAS –

An ideal combination

Besides the innovative mechanical concept of the ODM-WeighTUBE® RWS series, ODM developed a novel concept which is able to compensate typical practical problems which are accompanied with RDF dosing, such as limited flowability or varying material properties (i. e. bulk density and humid-ity). Besides that, it was obvious that many existing weigh feeders on the market are distributed with a proprietary controller architecture and hardware, which typically limits the degrees of freedom for the integration of a weigh feeder within an existing automation system.

Thus, the development of the ODM-GravitAS control system for ODM-WeighTUBE® was driven by the aim to provide a highly accurate and robust dosing controller which can be implemented in an open and highly modularized electrical automation platform.

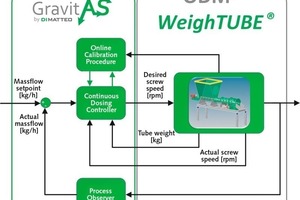

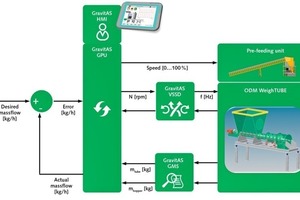

A diagram, which shows the relationship between the mechanical platform of the ODM-WeighTUBE® and the ODM-GravitAS control system, is visualized in Figure 2. The mechanical platform consists of a feed hopper, which acts as a material buffer and dosing device, a variable speed screw for discharging and dosing of the material and a measuring tube, where the actual material weight is provided by a set of load cells. The innovative mechanical design provides a maximum insensitivity against harmful impurities and allows easy maintenance within compact dimensions (see also [2]).

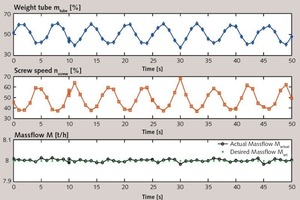

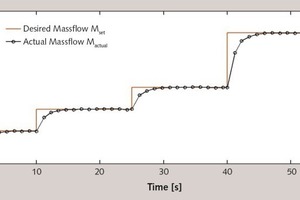

The continuous dosing controller of the GravitAS control system is responsible for the screw speed adaption based on the actual tube weight. Here, an inverse relationship between measured weight and actual screw speed leads to a continuous, stable and constant mass flow, as shown in Figure 3. The controller itself is based on a classical discrete PID-control structure, but contains certain interfaces to an additional online calibration routine, which is responsible for a continuous auto-tuning of the controller parameters.

The controller parameters can be set during the commissioning of the system in order to meet the desired process behavior defined by the specialists in the plant, where e.g. a highly dynamic variation of the throughput without any overshooting behavior can be achieved, as shown in Figure 4.

An implemented process observer calculates from actual process entities the current massflow indication, which is then the base for a readjustment of screw speed.

3 Adaptive control and auto-tuning

for long-time stability

As already stated above, all existing dosing methodologies are suffering immensely from the time-variant material properties of RDF. This leads in practical applications to a non-negligible drift in the dosing accuracy over time. So, classical weigh feeders, such as belt weigh feeders, need to be recalibrated on a regular basis (e.g. once a month) in order to guarantee a long-term stability of the feeding process. This re-calibration needs to be done manually by service technicians in a time-consuming process, during which the machine has to remain offline.

In comparison to that, the ODM-GravitAS control system implements an automatic calibration routine, which provides the possibility to estimate properties of the dosed bulk material and automatically adapt the controller parameters in such a way that the dosing accuracy remains stable over time. The actual process operation is not influenced by the execution of the automatic calibration routine, so that the available machine time can be increased.

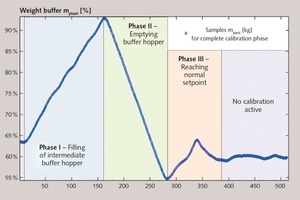

During the automatic calibration routine the intermediate buffer hopper of the ODM-WeighTUBE®, whose total weight is also measured by load cells, is filled to a certain maximum in a first stage of operation. Within the second phase the buffer hopper is emptied by normal dosing operation (and parallel feed of material to the buffer is stopped) up to a predefined minimum buffer weight. From the resulting difference in mass (m) and the corresponding expired time (t), the actual control parameters of the continuous dosing controller are automatically adapted. To avoid possible undesired influences, all controller parameters are checked for plausibility based on a probabilistic analysis of former calibration cycles, before they become active in the system. A typical calibration process, with its three phases, is shown in Figure 5, where the actual buffer weight mplant [kg] is visualised over time.

The decreasing buffer weight in phase II of the calibration process follows an almost exact linear pattern, which can be interpreted as a manifestation of the highly constant material throughput of the device. A possible deviation between the actual and the desired massflow during this phase is evaluated for the probabilistic adaption of the controller parameter.

The possibility for a continuous on-the-fly auto-tuning of the controller depending on the given material properties is a very important element for long-time stability and accuracy of the gravimetric dosing. In particular, if the decreasing quality of alternative fuels derived from industrial waste (see [3]) is taken into account. By the combination of the ODM-WeighTUBE® platform with the GravitAS control system a high dosing precision of < ± 1 % related to the nominal throughput can be guaranteed.

4 Tailor-made open automation

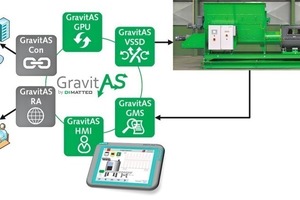

The GravitAS control system follows a highly modularized and open concept, which allows integrators and users of the ODM-WeighTUBE® to get exactly the system they want. Instead of using a closed and proprietary system setup, all electrical components can be chosen based on the standards and needs of each individual plant. Figure 6 gives an overview of the different modules of the GravitAS control system (four mandatory modules (green) and two optional elements (gray)).

The main element is the GravitAS GPU, which is the central processing unit and implements all program routines of the used control algorithm. ODM provides a great variety of standard PLC systems, which can be chosen as the main platform (Siemens S7®, Schneider Modicon®, Allen-Bradley Logix®, Beckhoff TwinCAT® etc.). Thus, the integration within the plant’s automation structure is very easy and cost effective and later maintenance and troubleshooting can be done by personnel at the plant without any additional expensive training and or the necessity of purchasing new software. In the same way, the manufacturer and the type of the screws frequency converter (as an element of GravitAS VSSD) can be chosen freely. The other mandatory elements contain the weighing units (GravitAS GMS) and a touch panel based human-machine interface (GravitAS HMI).

As optional modules, the GravitAS CON contains all necessary elements for a field bus driven signal exchange (e.g. Profibus, EtherCAT, DeviceNet, etc.), while GravitAS RA allows a GSM or Ethernet based remote access and maintenance. All these elements are combined within an electrical cabinet, which is tailor-made for every new customer.

The complete system (ODM-WeighTUBE® and GravitAS control cabinet) is fully assembled, tested and has undergone a quality control procedure, before the different components are delivered to the site of their later operation. Figure 7 shows an example of a fully assembled dosing device. By this, the necessary time frame for the commissioning of a new plant can be reduced to a minimum.

Figure 8 shows the complete concept of the control engineering process, where the different physical entities, the GravitAS modules and the signal flow are also visualized.

5 One control system – different dosing systems

The modular concept of the GravitAS control philosophy was the basis for the necessary flexibility in order to implement the same system setup for the other dosing and metering devices from Di Matteo, where the belt weighing system ODM-GraviSCALE (see Fig. 6) is the most prominent example. Since, the hard- and software implementation of the GravitAS control system is following a strictly modular philosophy, the end-users of the metering device are able to design their own GravitAS system setup based on the given requirements of the particular plant and ODM provides the same automation system architecture for all dosing and metering devices. By this, the integration of the Di Matteo dosing devices can be realised easily, because the integration into the existing control and automation architectures is possible without much effort.

6 Conclusions

The ODM-GravitAS full modular and open control philosophy allows the implementation of tailor-made control systems which are able to cover all requirements of each individual plant. The hard- and software concept was designed in order to be implemented with different dosing and/or metering devices, such as the ODM-WeighTUBE® tubular dosing unit, the ODM-GraviSCALE belt weigh feeder or even differential dosing systems. Thus, there is the possibility to implement a single architecture for all gravimetrical feeders, where the algorithms are implemented by using standardised PLC programming languages, such as Siemens S7® or IEC61131-3. It is also possible to combine the necessary algorithms for controlling more than one dosing unit into a single PLC. This guarantees a cost-efficient daily operation of the equipment and minimised machine down-times, e.g. during maintenance phases.

Furthermore, the implementation of the ODM-GravitAS system for the novel ODM-WeighTUBE® RWS series includes the implementation of an innovative probabilistic on-the-fly online calibration algorithm, which provides the possibility for a long-time accurate and stable dosing of bulk material. The novel concept of the adaptive gravimetric controller has shown that it is able to outperform classical dosing methodologies in particular for problematic bulk materials with time-variant material properties, such as all solid alternative fuels (e.g. RDF, SRF, municipal waste, biomass, animal meals or dried sludge). More recently the system design was also successfully implemented for the dosing of bulk material with more stable characteristics, such as iron core, slag, cement, etc. within the cement industry. Di Matteo is also offering a specific service, where potential clients can test their own bulk material within the ODM’s testing facility, as shown in Figure 10, in order to guarantee during an early project stage, that the chosen dosing technology (e.g. ODM-WeighTUBE® or ODM-GraviSCALE) delivers the optimum accuracy and robustness.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.