The Maerz hybrid kiln for variable

lime reactivity

At the International Lime Association’s General Assembly and Information Exchange Forum in October 2019 in Buenos Aires/Argentina, Maerz Ofenbau AG introduced a new kiln type permitting the production of lime with variable reactivity by combining the thermal efficiency of the parallel flow regenerative process with the features of a counterflow kiln.

1 Introduction

The development of modern lime kilns to date has been focusing on the optimisation of the specific heat consumption as well as on the flexibility to use a wide variety of fuels. Little attention was paid to the flexibility of producing lime with variable reactivity. Hence, the kilns were either optimised to produce high reactive lime with the Parallel Flow Regenerative (PFR) lime kiln, originally invented by Maerz Ofenbau AG, as being one of the most commonly built kiln types throughout the world, or to produce medium or low reactive lime, with mainly single shaft kilns based on...

1 Introduction

The development of modern lime kilns to date has been focusing on the optimisation of the specific heat consumption as well as on the flexibility to use a wide variety of fuels. Little attention was paid to the flexibility of producing lime with variable reactivity. Hence, the kilns were either optimised to produce high reactive lime with the Parallel Flow Regenerative (PFR) lime kiln, originally invented by Maerz Ofenbau AG, as being one of the most commonly built kiln types throughout the world, or to produce medium or low reactive lime, with mainly single shaft kilns based on the counterflow process (such as the Maerz HPS kiln), or rotary kilns.

In comparison with PFR kilns, single shaft coke-fired kilns (mixed-feed kilns) have a higher specific heat consumption and also their CO-emissions are high due to less favourable combustion conditions, compared with PFR kilns. Rotary kilns have a significantly higher flame temperature and heat consumption compared with PFR kilns and hence generally more noxious emissions due to their higher fuel consumption. Furthermore, with only specialised kilns being available on the market, lime producing companies have been forced to install two different kiln types, even when only comparatively small quantities of medium or hard burnt lime have to be produced.

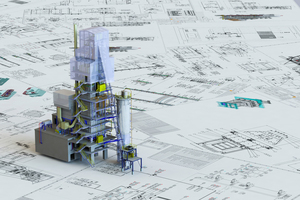

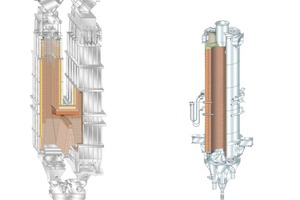

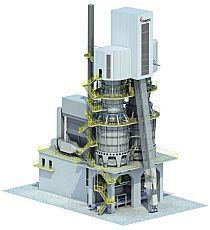

To overcome this problem, Maerz patented a hybrid kiln, combining the advantages of a Maerz PFR kiln for the major part of the calcination with the design of a Maerz HPS kiln for completing the calcination and for post-treatment of the lime, to achieve medium or hard-burnt lime depending on the requirements of the lime plant. Figure 1 shows a Maerz PFR kiln with its characteristic double-shaft design and the Maerz HPS single shaft kiln with laterally adjustable liquid-cooled burners protruding into the material bed at the lower end of the burning zone.

2 Characteristics of high reactive,

medium and hard-burnt lime

The reactivity of quicklime is determined mainly by two factors:

(1) The availability of CaO in the quicklime, which is dependent on the CaCO3-content of the limestone to be processed and the resulting various chemical reactions between CaO and impurity components (such as SiO2, Fe2O3, Al2O3), which consume part of the CaO, forming various minerals such as clinker components known from the cement industry.

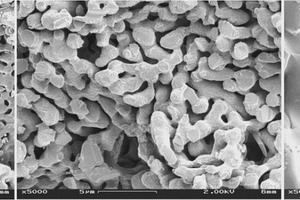

(2) The specific surface of the CaO crystallites in the quicklime, which may be directly translated to the size of these crystallites: the smaller they are the larger the specific surface and hence the higher the quicklime’s reactivity will become.

When burning quicklime the highest reactivity is achieved right at the completion of the calcination process, when the thermal energy has been absorbed by expelling all CO2 from the carbonate leaving the piece of quicklime at its highest porosity. If the quicklime is further exposed to heat, the thermal energy will be used to increase the temperature of the quicklime thereby inducing a sintering process of the CaO crystallites, which reduces their specific surface and – as a consequence – reduces the reactivity of quicklime. Various studies have shown that just prolonging the exposure time at the same temperature level would result in little or no reduction of the quicklime’s reactivity. Increasing the temperature, however, will jump-start the sintering process.

Depending on the properties of the limestone, high reactive lime may be produced best at a temperature level of between 950 and 1050°C. In order to produce hard burnt lime, temperatures up to typically 1550°C may be necessary, again depending on the properties of the limestone.

Figure 2 shows SEM (Scanning Electron Microscope) analyses of lime samples burnt at 1050, 1450 and 1850°C (from left to right). The effects of the sintering process may be clearly seen in these photos.

3 Operating principle

of the Maerz hybrid kiln

In its upper part, the Maerz hybrid kiln is a classic PFR kiln with a direct crossover channel introducing the fuel into the material bed by air-cooled burner lances. The hybrid kiln features an extended lower part comprising a cooling zone as well as a sinter zone located between the burning zone and the cooling zone. In this sinter zone liquid-cooled side burners are installed in the walls opposite the crossover channel, each of which is horizontally adjustable to optimise its insertion depth. This allows for the additional injection of fuel to complete the calcination process and to adjust the lime reactivity. A cross section of the hybrid kiln is depicted in Figure 3.

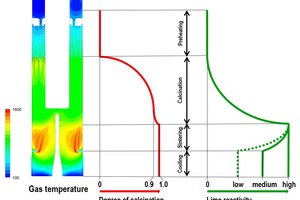

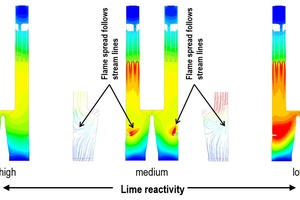

In the burning zone in the upper part of the hybrid kiln, the limestone is calcined in parallel flow to a degree of approximately 90%. The material then enters the sinter zone, where calcination is completed and the quicklime may be exposed to additional heat so that – due the CaO crystallites’ growth and eventually their sintering – the desired quicklime reactivity is achieved. Figure 4 shows the gas flow and the calcination curve in a Maerz hybrid kiln. Depending on the quantity of fuel fed to the burners in the sinter zone the kiln will produce high, medium or low reactive lime: if the burners are switched off, the kiln operates in the mode of a classic Maerz PFR kiln and produces high reactive lime. When the burners are in operation, medium or low reactive lime can be produced with process temperatures reaching up to 1500°C depending on the properties of the limestone and the desired reactivity. Figure 5 shows the gas temperatures in the kiln depending on the quantity of fuel fed through the side burners.

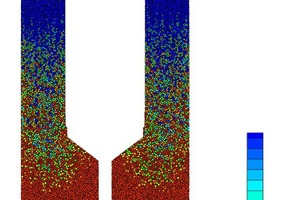

Figure 6 shows the degree of calcination in the material bed as calculated by a combined CFD-DEM (Computational Fluid Dynamics and Discrete Element Method) simulation. It is clearly visible that some material calcined to a lesser degree is still present below the burning zone before entering the sinter zone.

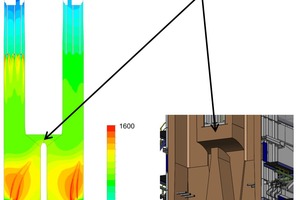

This not yet fully calcined material acts as a temperature sink by absorbing the thermal energy introduced by the burners in the sinter zone to complete calcination (a highly endothermic chemical reaction) thereby reducing the temperature of the gases leaving the sinter zone and passing through the crossover channel. This prevents overheating of the refractories, especially of the arches in the crossover channel, as can be seen in Figure 7.

4 Heat consumption and CO2 emissions

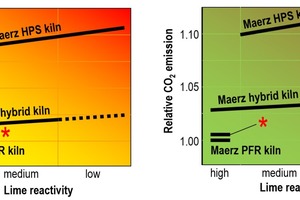

Figure 8 shows the heat consumption and CO2 emissions of the Maerz hybrid kiln in comparison with the classic Maerz PFR and Maerz HPS kiln. In both diagrams the reference point for the Maerz PFR kiln is set to 1.0 with the specific heat consumption and the CO2 emission being based on a kiln fired with fossil fuel. On the horizontal axis of the diagrams the desired reactivity of the lime produced is plotted and on the vertical axis the relatively higher heat consumption/CO2 emission is shown. Whereas the PFR kiln can only produce high reactive lime, the lines for the Maerz hybrid kiln extend to medium and low reactive lime, the production of which requires a higher specific heat input and emits more CO2 than the calcination of high reactive lime.

When operating the Maerz hybrid kiln in classic PFR mode to produce high reactive lime (without introducing fuel to the burners in the sinter zone and the burners therefore being in a retracted position), the specific heat consumption and CO2 emissions are slightly higher than in the classic Maerz PFR kiln (line marked with a red asterisk in the diagrams). This is due to the elongated design of the lower kiln part, which leads to a slightly higher heat loss by radiation through the kiln shell.

5 Advantages and fields of application

of the Maerz hybrid kiln

The Maerz hybrid kiln combines two technologically proven designs developed by Maerz which are already in operation in many kilns world-wide. It gives a lime producer the maximum flexibility when serving customers requiring various quantities of soft, medium and hard-burnt lime, making the necessity for a dedicated kiln for hard-burnt lime redundant.

From an environmental perspective the Maerz hybrid kiln has clear advantages over the classic kiln types for producing medium and hard-burnt lime, namely coke-fired single shaft kilns, rotary kilns and even Maerz HPS kilns. Its overall lower heat consumption and optimised combustion conditions result in significantly lower emissions of CO and other noxious gases and keep the CO2-footprint of the lime plant far smaller.

With the overall lower Capex costs compared to installations with two dedicated kilns for each type of product and its lower operating costs, the Maerz hybrid kiln will become the favourite choice for successful lime producers in a highly demanding market.

//www.maerz.com" target="_blank" >www.maerz.com:www.maerz.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.