Industrial application of the kiln gas

bypass quenching chamber and its new development

While it is easy to arrange a new bypass system in a new designed cement line, it is a challenge to implement it in existing production lines, due to limited space which makes it difficult to design. Considering this bottleneck, a second generation quenching chamber and bypass process has been developed to make it suitable for existing plants. It can be feasibly installed into all kinds of clinker production lines so as to improve the ratio of alternative fuel utilization.

1 Introduction and objectives

One important way to reduce CO2 emission is by steadily increasing the use of alternative fuels [1] to realize the target of CO2-neutral cement production by 2060 or even earlier. When using alternative fuels, it is necessary to install a bypass system [2, 3] to deal with the hazardous elements circulation of Cl, S, alkalies and especially Cl to avoid builds-up and coatings. It is easy to arrange a new bypass system in a new designed cement line; however, it is a challenge for existing production lines because of the limited space between the existing equipment...

1 Introduction and objectives

One important way to reduce CO2 emission is by steadily increasing the use of alternative fuels [1] to realize the target of CO2-neutral cement production by 2060 or even earlier. When using alternative fuels, it is necessary to install a bypass system [2, 3] to deal with the hazardous elements circulation of Cl, S, alkalies and especially Cl to avoid builds-up and coatings. It is easy to arrange a new bypass system in a new designed cement line; however, it is a challenge for existing production lines because of the limited space between the existing equipment which makes it difficult to design. Considering this bottleneck, a second generation quenching chamber and bypass process has been developed to make it suitable for existing plants. It can be feasibly installed into all kinds of clinker production lines so as to improve the ratio of alternative fuel utilization.

2 Principle and modification

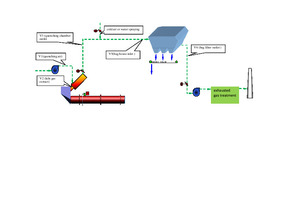

A bypass system extracts a certain amount of hot flue gas from the kiln inlet chamber, rapidly cools it and discharges it outside the kiln system, so as to reduce the circulating enrichment of volatile components, especially chlorine, in the flue gas. Bypass technology is one of the most important measures to solve the problem of harmful element enrichment when burning alternative fuels in the cement kiln. The conventional bypass process is shown in Figure 1: part of the hot gas is extracted from the kiln inlet chamber. As the hot gas meets the cold air in the quenching chamber, the harmful elements in the hot gas are cooled and enriched in fine particles because of the lower temperature. The dust containing the harmful elements flows through the quenching chamber outlet into the dust collector, and is then collected and discharged from the kiln system. The gas after the dust collector passes into the exhaust gas treatment system or the cooler system to recover the heat and deal with the NOx or dioxins. Sometimes a cyclone would be arranged between the quenching chamber and the bag house to return a part of the coarse dust to the kiln system in order to reduce the dust load when operating the bypass, such as in the Jiaozuo project in Figure 2 on the right-hand side.

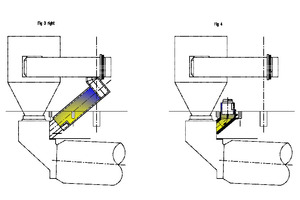

2.1 Limitation and problems of the first generation quenching chamber

The first generation quenching chamber has been widely used in several plants designed by our company, such as shown in Figure 2, an Egyptian plant and a Chinese plant. However, it has large size specifications, which limits its utilization in existing lines. For example, a Chinese cement plant named Tianjin Zhenxing belonging to the BBMG Group (hereinafter referred to as “Tianjin plant”), shown in Figure 3, is scheduled to use AF to reduce the carbon emission and has to be modified by adding a bypass system. Due to the small height of the kiln riser duct surrounded by the beam and columns, it would have to be laid flat to facilitate the installation, which would aggravate the coating and have the negative effect of harmful component enrichment in the fine powder. The chamber would not be able to effectively recover the coarse particle dust, resulting in increased material consumption of the cement kiln system because of the large amount of ash from the bypass discharge system. On the other hand, if one of the beams were moved it would increase the civil construction cost.

2.2 Development of the second generation quenching chamber

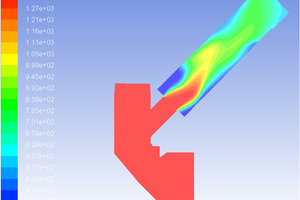

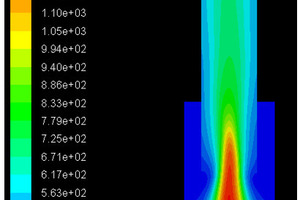

To be suitable for existing lines, the second generation quenching chamber has been developed. It is composed of the outer cylinder, inner cylinder and the inlets for hot gas and cold air. The quenching section is connected to the kiln inlet chamber through the settlement pipe as the hot gas inlet. The hot flue gas is extracted through the settlement pipe into the quenching section; cold air flows from the inlet to the circular space between the outer cylinder and the inner cylinder, comes into contact with the hot flue gas and rapidly cools it. The cooled mixed gas flows into the inner cylinder, is discharged through the quenching chamber outlet, and then it completes the quenching process.

The inner cylinder causes the cold air to flow back, to force mixing of hot and cold gases, and can further reduce the length of the quenching section; in addition, the shorter inner cylinder length facilitates entry of the gas into the inner cylinder through the inlet at the lower part of the inner cylinder. The gas is transported to the exit of the quenching chamber, which can significantly reduce the resistance of the quenching chamber.

Due to the high flue gas temperature in the kiln inlet chamber (normally 1050-1150 °C), the settlement pipe is equipped with a refractory lining of 250 mm to ensure its service life, and multiple air cannons are provided in this part to prevent coating and builds-ups. The design section gas velocity of the settlement pipe is controlled to less than 10 m/s, and a large amount of coarse particulate material is returned by the hot flue gas to the kiln system after settlement. The fine particulate material with small particle size and strong harmful element enrichment ability enters the quenching chamber, reducing the amount of dust passing into the bypass discharge system.

The fan blows a large amount of cold air into the annular space between the outer cylinder and the inner cylinder. The cold air enters at a high velocity to ensure the mixing effect and cooling efficiency of the hot and cold air. The forced return flow of the cold air outside the inner cylinder makes the cold air mix with the hot flue gas at the bottom of the annular space and exchanges the heat. A refractory material with a thickness of 100 mm is installed on the inner wall. The cooled mixed gas enters the inner cylinder and then reaches the outlet with the controlled temperature of 200-420 °C.

The second generation quenching chamber can be arranged inclined or vertically according to the existing preheater tower space. The overall length of the equipment is short, and the support can also be flexibly arranged according to the actual situation. As shown is Table1, the second generation quenching chamber with a lower weight as well as lower civil construction cost is more suitable for transformation of existing production lines. The second generation of bypass quenching chamber technology can be adapted to different production conditions.

3 Application of the new quenching chamber

technology

Through theoretical analysis and numerical simulation, the scheme of the Tianjin plant has been developed with the second generation bypass quenching chamber. It has been greatly optimized and improved in structure compared with the first generation quenching chamber shown in Figure 2 as example. As shown in Table 1 and Figure 6, under the same operating conditions the second generation bypass quenching chamber could be installed in a very limited space. It is also shown in Figure 6 that the cooling method after the quenching chamber is an indirect air cooler combined with the bag filter, which reduces the area of the bypass system modification. It has been running for several months in 2021 producing a better effect, as shown in Table 2 and Table 3. The Cl in the clinker product could be controlled to below 300 g/t∙clinker by the bypass system to condense it in the cement kiln bypass dust at a rate of 6.42 times compared to the content in the C5 hot meal to the kiln. The removal rate of Cl can reach more than 80%. Ranged in the same cooling temperature, the gas residence time is shorter, and the clinker chlorine content meets the quality requirements. The equipment specifications are small, bringing the advantages of flexible layout and lower civil construction cost.

4 Summary

The quenching chamber has been developed from the first generation to the second generation to meet the demand of alternative fuel utilization in existing production lines. It has been very effective across the research and development in reducing the CO2 emission. According to the research results and application practices, it is summarized as follows:

With the methods of numerical simulation experiment and theoretical calculation analysis, the newly developed second generation quenching chamber with an outer cylinder and an inner cylinder significantly improves the rapid cooling of the hot gas with harmful volatile components.

The quenching chamber is connected by a settling pipe equipped with refractory materials and air cannons. The design of the settling pipe ensures a low gas velocity. The coarse particles in the hot flue gas settle and are returned to the cement kiln system. The fine particles that collect a large amount of harmful components are discharged through the outlet, and the removal rate of Cl can reach more than 80%.

The size of the quenching chamber is greatly reduced compared with the previous first generation. Under the same operating conditions, the volume of the new generation bypass discharge quenching chamber is reduced by about 75%, enabling easy installation, and the civil construction cost is lower.

More and more cement plants face the stress of carbon reduction not only in China but also abroad [4]. This new quenching chamber provides more opportunity to utilize a high rate of alternative fuel and raw materials for cement production. It has been scheduled for application in the technical transformation projects of several cement production lines. Adjusting the specifications of the quenching chamber would meet the requirements of the process flow to improve the bypass efficiency. It makes a significant contribution for a reduction of carbon emissions in cement plants.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.