Applications of a bypass system in Chinese cement plants

Due to raw fuel, waste disposal, or using of alternative fuel and other reasons, chlorine and other harmful elements in the cement kiln circulate and accumulate in the burning system, resulting in serious scaling and blocking, affecting the stable operation of the burning system and clinker quality. The author introduces several typical applications of bypass system in Chinese cement plants to address these issues.

1 Introduction

In cement production, harmful elements such as potassium, sodium, chlorine, and sulfur are recycled and enriched in the burning system, which can cause serious impacts, including severe scaling and blockage in the kiln tail smoke chamber, feeding slope, final stage cyclone cone, and other parts. It also affects the stable operation of the burning system and the quality of the clinker [1]. With the rapid development of the cement industry, the resources of raw materials are becoming increasingly scarce, and cement production has to adapt to raw fuels with high volatile harmful...

1 Introduction

In cement production, harmful elements such as potassium, sodium, chlorine, and sulfur are recycled and enriched in the burning system, which can cause serious impacts, including severe scaling and blockage in the kiln tail smoke chamber, feeding slope, final stage cyclone cone, and other parts. It also affects the stable operation of the burning system and the quality of the clinker [1]. With the rapid development of the cement industry, the resources of raw materials are becoming increasingly scarce, and cement production has to adapt to raw fuels with high volatile harmful components. In addition, with the increase of the amount of solid waste, domestic garbage, fly ash and other wastes co-disposed by the cement kiln, or the use of alternative fuel, the volatile harmful components entering the rotary kiln will also increase accordingly. The risk of harmful element enrichment will become more and more serious. To reduce risk, many cement plants in China have installed bypass systems.

The bypass technology refers to the extraction of flue gas containing high concentrations of volatile harmful components from the kiln inlet chamber. The harmful elements are condensed on the surface of the ash due to flue gas cooling, and released from the system along with the bypass ash through gas-solid separation. Generally, the ventilation ratio of the alkali bypass is generally 20%~30%, and the ventilation ratio of the chlorine bypass is generally 5%~10% [2].

There are three main forms of bypass systems used in China, one is the two-stage cooling bypass system, one is the two-stage cooling & cyclone bypass system, and the last is the waste heat recovery bypass system.

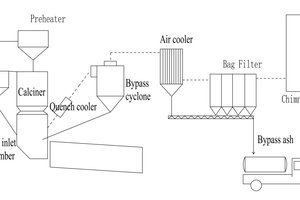

1.1 The two-stage cooling bypass system

The two-stage cooling bypass system is generally used in the plant for waste collaborative disposal or alternative fuel. Figure 1 shows the process flow of the two-stage cooling bypass system. The core of the two-stage cooling bypass system is a two-stage cooling system composed of a quench cooler and an air cooler [3]. After taking flue gas from the kiln inlet chamber, the bypass system adds a large amount of air to cool bypass flue gas to around 400 °C in the quench cooler, and then passes through the air cooler for secondary cooling to below 200 °C. The harmful components are condensed on the surface of the ash due to flue gas cooling. At the same time, the air cooler releases the rich harmful elements ash. More harmful elemental ash is collected by the dust collector and sent for treatment with the ash from the air cooler. The system has a relatively high content of exhaust dust, but the concentration of chloride ions in chlorine rich alkali ash is high and the amount of exhaust gas is small. This system is mainly suitable for the appropriate treatment of vented ash in the factory – adding it as a mixture to cement.

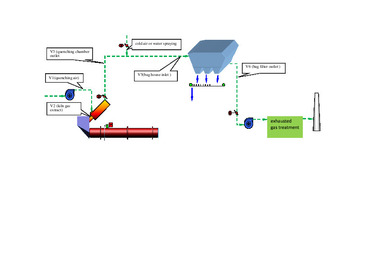

1.2 The two-stage cooling & cyclone bypass system

The two-stage cooling & cyclone bypass system is also used in the plant for waste collaborative disposal or alternative fuel. Figure 2 shows the process flow of two-stage cooling & cyclone bypass system. Compared to the two-stage cooling system, the two-stage cooling & cyclone system adds an additional cyclone for separating large particles of ash [3]. After taking flue gas from the kiln inlet chamber, the bypass flue gas cools to around 400 °C in the quench cooler by adding a large amount of air. After the quench cooling, the bypass flue gas passes through the cyclone for preliminary dust removal, and the large particles ash returns the burning system. After the preliminary dust removal, the bypass flue gas is cooled by the air cooler and then enters the bag filter to collect the rich harmful elements ash. This system releases a smaller amount of the rich harmful elements ash than two-stage cooling bypass system because of the returning of the large particles ash. This system is suitable for the plant which cannot dispose of bypass ash. Due to the high chloride content in the bypass air ash, it usually needs to be treated as hazardous waste outside the factory.

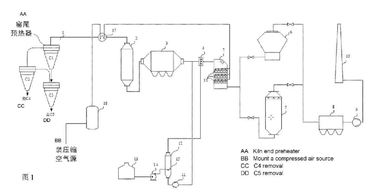

1.3 The waste heat recovery bypass system

The flue gas temperature for bypass ventilation generally ranges from 1000 to 1100 °C. If heat recovery is not carried out, it will increase the heat consumption of the production system [4]. In order to reduce heat loss, the waste heat recovery bypass system has been proposed, and a PH furnace for waste heat recovery has been added to this system. Figure 3 shows the process flow of the waste heat recovery bypass system. After being taken out of the flue gas chamber at the kiln end, the bypass exhaust gas enters the PH furnace through an upward pipeline for waste heat power generation. The low-temperature gas generated after power generation is dust removed and discharged from the chimney. The bypass vent ash collected from the PH furnace and dust collector will be sent for specialized disposal.

2 Bypass system of the cement kiln for collaborative

disposal of solid waste

2.1 Overview

Collaborative disposal of solid waste is one of the important environmental protection functions of cement kilns. A cement plant in North China uses its own 2000 t/d clinker production line to dispose of solid waste including sludge, hazardous waste, and general solid waste. This solid waste is generated by nearby cities. The disposal capacity of solid waste in this cement line is 120 t/d. According to statistics and calculations, the average chloride ion content of solid waste is 0.528%, the chloride ion content of raw materials is 0.032%, and the average chloride ion content of kiln materials is 0.06%, which is far higher than the requirement for normal operation of cement kilns for chloride ion concentration (less than 0.015% for kiln materials).

2.2 Retrofit of bypass system

To address the risks posed by high chlorine raw materials and solid waste, the cement plant has undergone a “two-stage cooling bypass system” renovation. The main objective of this bypass system retrofit is to remove chlorine, and the designed bypass flue gas volume accounts for 10% (about 4700 Nm3/h) of the total flue gas flow in the kiln inlet chamber. The first stage of cooling is completed by mixing a large amount of air and the bypass flow gas in the quench cooler. The bypass flue gas temperature rapidly decreases from 1100 °C to 420 °C. Then, the bypass flue gas is cooled to below 200 °C through an air cooler to achieve secondary cooling.Due to the indirect heat exchange of the secondary cooling, it can reduce the processing air volume of the subsequent system.The cooled bypass flue gas is released after dust removal.The bypass ash collected by the air cooler and dust filter is a total of 3 t/h. The bypass ash enters cement as a mixture.

2.3 Retrofit effect

After retrofit, during the operation of the cement plant, the chlorine removal effect was significant, and there were no serious problems such as scaling and blockage in the production system. The harmful elements content of the final cyclone raw material is a direct reflection of the circulation of harmful elements in the kiln system, so the ratio of harmful elements in the bypass ash to final cyclone raw material can directly reflect the effect of the bypass system. This ratio data is referred to as the enrichment factor in this article. Table 1 shows test results of the harmful elements content in the final cyclone raw material, clinker, and bypass ash under two working conditions. The data shows that the bypass system has a relatively good enrichment effect on K2O and chloride ion, with enrichment factors of 4.06-6.21 for K2O, 5.47-5.99 for chloride ion, and 1.7-2.0 for Na2O. The highest chloride ion content in the bypass ash is 12.9%, significantly reducing the accumulation and cycling of harmful elements in cement kilns. The release effect of alkali chloride is significantly better than that of alkali sulfate, mainly due to the difference in melting and boiling points between these two types of substances. Chlorinated alkali is volatile, while sulfuric acid alkali is difficult to evaporate. On the contrary, sulfuric acid alkali is more prone to condensation than chlorinated alkali [1].

3 Bypass system for collaborative disposal of

household waste in cement kilns

3.1 Overview

There are many application cases in China where cement kilns collaborate to dispose of household waste. A cement plant in central China uses a 5000 t/d clinker production line to collaborative dispose of 450 t/d household waste. The cement plant adopts a pre-sorting system to sort household waste into combustible waste, inorganic waste, metal waste, and leachate. Through pre-sorting, about 10 t of combustible waste can be obtained from 450 t of household waste and fed into the calciner to replace some coal powder combustion. Through testing, the comprehensive average moisture content of combustible waste is about 45%, the average mass fraction of chlorine element is 0.456% as received, and the chlorine content of feeding raw materials is 0.020% by mass percentage.

In the process of collaborative disposal of household waste, the chlorine content in the final cyclone raw material can reach up to 2.0%, and there are phenomena of scaling in the release pipe of the final cyclone, kiln inlet chamber, and kiln. To solve the scaling problem, this plant has carried out a bypass system transformation.

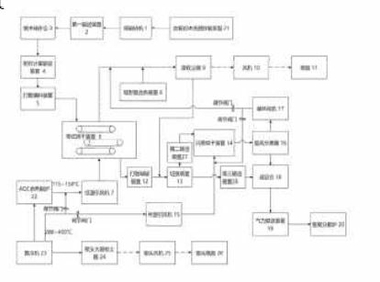

3.2 Retrofit of bypass system

The bypass system of the plant adopts the technological process of “two-stage cooler and cyclone”. A gas distribution pipeline is added at the kiln inlet chamber. The dusty hot bypass flue gas flows into the quench chamber and is fully mixed with the cold air blown by the fan for cooling. The bypass flue gas temperature at the outlet of the quench cooler is controlled below 370 °C and enters the cyclone dust collector. The coarse ash particles are collected and returned to the kiln. The fine ash particles enter the air cooler with the bypass flue gas and are cooled again to around 220 °C before entering the dust collector. The bypass ash collected by the air cooler and dust filter is a total of 1 t/h. The bypass ash is sent to disposal outside the plant as hazardous waste [5].

3.3 Retrofit effect

After the retrofitting, the bypass system and collaborative disposal system for household waste operate well. Table 2 shows test results of the harmful elements content in final cyclone raw material, clinker, and bypass ash under two working conditions. It can be seen that when the bypass flue gas volume is about 5%, the chlorine content of the final cyclone raw material is basically around 1.2%, and the chlorine content of the bypass ash is 14.76%; when the bypass flue gas volume increases to 7%, the chlorine content of final cyclone raw material decreases by about 1.1%, and it is detected that the chlorine content in the bypass ash is 18.26%. This indicates that it is beneficial for the release of chlorine elements with the increase of the bypass flue gas volume.

In addition, compared to the chloride ion concentration of cyclone dust collector ash and bypass ash, there is a significant difference in the distribution of harmful chlorine elements in solid particles. The adsorption capacity of fine ash for chlorine is much greater than that of coarse ash. The chlorine content of fine ash is 19.5%, while the chlorine content of coarse ash is 1.63%. The chlorine content of fine ash is about 12 times that of coarse ash, but the mass of coarse ash accounts for a relatively large proportion, about 82.95%. Therefore, it is necessary to reasonably design the separation efficiency of the cyclone dust collector. A high separation efficiency of a cyclone can reduce the removal efficiency of harmful elements. On the contrary, a low separation efficiency of a cyclone requires handling more bypass ash and wasting more heat. Based on operating experience, it is reasonable to control the dust collection efficiency of the bypass cyclone between 83% -87%.

4 Bypass system for the cement plant using

high sulfur coal

4.1 Overview

A cement plant in northwestern China has a 5000 t/d clinker production line using locally produced high sulfur coal in order to obtain better economic benefits. After testing, the sulfur content of the local coal reaches 2.5%. Many problems have arisen in the process of using local coal to produce clinker. There are solid and difficult to remove crusts and circles in the kiln head and decomposition furnace. According to the test, the crust consists of acicular or fibrous crystal minerals such as sulfo silicate (2C2S · CaSO4), calcium alunite (2CaSO4 · K2SO4), and calcium aluminates sulfate (3CA · CaSO4) [6]. The sulfur content in the clinker is high, the strength of the clinker decreases, the cement setting time is abnormal, and the amount of gypsum added is difficult to control. Long-term strength of clinker is affected due to the alkali content of 1.36%. Table 3 shows the composition test results of the raw material and clinker of this production line.

4.2 Retrofit of bypass system

In order to solve the problems encountered in production and produce qualified clinker, the production line has undergone a bypass system retrofit. The bypass system of the plant adopts the technological process of ‘the waste heat recovery bypass system’. The vent point is directly in front of the slope of the kiln inlet chamber, and a long low wind speed rising flue replaces the quenching cooler. A nearly 36 m rising flue is used to settle some larger particle materials, reduce ash release, and improve the ventilation environment of the flue. At the top of the rising flue, the flue gas directly passes through the PH furnace for waste heat power generation, with a power generation capacity of 400 kW/h. The low-temperature gas generated by the PH furnace is discharged from the chimney after dust removal. This design effectively solves the problem of blockage in the bypass flue, enabling the bypass system to achieve continuous and stable operation and waste heat utilization. By setting up a bypass system, this plant can use local high sulfur coal and obtains more benefits.

4.3 Retrofit effect

By setting up a bypass ventilation system, the idea of using local high sulfur coal for production in this project has been realized, reducing production costs. Due to waste heat recovery, the heat loss and ash discharge from bypass ventilation are reduced. During normal production, the working conditions inside the kiln are in a clear state, and the tendency of kiln end skinning is weakened, making the operation easier. The content of harmful elements in the clinker is significantly reduced, the performance of the clinker is improved, the strength is increased to meet the standard. Table 4 shows the test results of the harmful elements content in clinker and bypass ash. Table 5 shows the clinker strength at standard consistency water consumption after bypass system retrofit.

5 Summary

A bypass system has a significant effect on dealing with the enrichment of harmful elements in cement kilns, but it requires a loss of some heat value and an increase in system heat consumption. Therefore, it is necessary to determine whether to use a bypass system based on a detailed study of the harmful composition of the raw materials. In the renovation of the bypass ventilation system, the process flow, location of ventilation points, and equipment should be well selected according to the situation. Of course, it cannot completely eliminate the phenomenon of scaling and blockage even if a bypass ventilation system is installed. Careful operation, stable temperature and pressure on the kiln and preheater, reasonable air guns and air cleaning devices in areas prone to scaling should be carried out to minimize the risk of skin blockage.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.