Increasing the availability of high-precision dosing systems by remote maintenance solutions and pro-active service

This article provides an overview of typical concepts and methods for the usage of remote maintenance procedures and corresponding proactive services by using the example of high-precision bulk material dosing systems. The technical aspects for the realization of remote access solutions are described against the background of heterogeneous IT-infrastructures in modern cement plants and actual IT security discussions. Furthermore, corresponding possibilities for a proactive service and maintenance concept are introduced. It can be shown that the reasonable implementation of such services leads to an enormous cost reduction and a parallel increase of the plant availability.

1 Introduction

Efficiency and cost reduction have become the most important economic drivers for cement plants worldwide, in order to guarantee a long-term profitability. In this context the optimisation of energy resources and raw material supply are important factors, which are already considered at most plants. However, a simultaneous increase of machine availability and the reduction of maintenance costs are not less important, in order to utilise the full potential of those measures.

Today the daily work within the cement industry, both at headquarters and plant offices, is mainly...

1 Introduction

Efficiency and cost reduction have become the most important economic drivers for cement plants worldwide, in order to guarantee a long-term profitability. In this context the optimisation of energy resources and raw material supply are important factors, which are already considered at most plants. However, a simultaneous increase of machine availability and the reduction of maintenance costs are not less important, in order to utilise the full potential of those measures.

Today the daily work within the cement industry, both at headquarters and plant offices, is mainly determined by economic drivers, such as the needs for increasing the production efficiency and capacity by a parallel reduction of costs for maintenance personnel and shorter return-on-investment (ROI) periods. These trends are the logical consequences of the actual act of global consolidation and market shake-outs within the whole industry, but especially in Europe after the financial crisis and the subsequent recession all over the south of Europe.

In this context the optimisation of energy resources and raw material supply are important factors, which are already considered at most plants. Thus the increased substitution of conventional fossil fuels by alternative energy resources is an ongoing process during the last decades and the utilisation of energy-from-waste concepts will speed up even more on a worldwide scale during the next years.

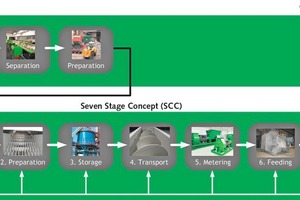

This ongoing development was accompanied and driven by the introduction of the Di Matteo Seven Stage Concept (SCC) for plants for the handling of alternative fuels (AFs). This concept, as depicted in Figure 1, summarises the thermal utilisation of AFs, e.g. within a cement plant, as a setup of machines from seven different stages, as described in detail in [1]:

1. Reception

e.g. plants for the reception of AFs from trailers, such as docking stations or from dumper trucks etc.

2. Preparation

Machinery for the preparation of the received material prior to the combustion process, such as screening (ODM-DiscScreen), magnetic separation (ODM-MAS), deagglomeration, drying etc.

3. Storage

Silo and bunker systems for the intermediate storage of AFs within the plant and their corresponding discharge systems, such as screw dischargers (ODM-ScrewDos), moving floors (ODM-MovingFloor), etc.

4. Transport

All types of conveyors for the transport of AFs in the plant, such as screw conveyors, drag chain conveyors, pipe conveyors, bucket elevators etc.

5. Metering

Metering devices for the gravimetrical dosing of AFs for a precise control of the combustion process (e.g. the ODM-WeighTube tubular weighing system, ODM-GraviScale belt weighers, etc.).

6. Feeding to the kiln process

e.g. the mechanical feeding of kiln inlets or calciners (e. g. by screw feeders, injectomizers etc.) or pneumatic feeding of main burners by injector rotary valves (ODM-IZS) and the corresponding pneumatic transport lines.

7. Combustion

Successful and efficient combustion of the AF. It is essential to realize that the successful substitution of higher rates of fossile fuels by AF requires the right combination and implementation of the previous process steps [1].

This concept has proven its applicability in a wide range of application fields in numerous installations all over the world. However, a simultaneous increase of machine availability and the corresponding reduction of maintenance costs are not less important than the aforementioned increase in efficiency and optimisation of energy resources, in order to utilise the full potential of those measures.

Di Matteo machines and installations are engineered and fabricated especially for the tough operational conditions in AF plants and therefore tailor-made for each customer by a former characterisation of the utilised fuels in terms of their thermal, physical and chemical properties. The corresponding wear resistant materials, which are partially developed within the companies’ own materials laboratory, guarantee a maximum life time.

Another important aspect which helps to increase the availability of AF feeding installations is the introduction of remote access and maintenance strategies during the conception of the auto-mation system. This article provides an overview of typical concepts and methods for the usage of remote maintenance procedures and corresponding proactive services, by using the example of high-precision bulk material dosing systems. The technical aspects for the realisation of remote access solutions are described against the background of heterogeneous IT-infrastructures in modern cement plants and actual IT security discussions. Furthermore, corresponding possibilities for a proactive service and maintenance concept are introduced. It can be shown that the reasonable implementation of such services leads to an enormous cost-reduction and a parallel increase of the plant availability.

The remainder of this article is organised as follows: chapter 2 provides a short overview of typical measures for the utilisation and reliability of technical installations. Subsequently chapter 3 contains an overview of typical systems accurate dosing and metering of AFs, while chapter 4 provides an introduction to modern remote access platforms and architectures and how those system can help to increase the availability of technical systems. In the fifth section a short case study for pro-active maintenance is carried out. Finally chapter six concludes the whole article.

2 Defining the availability of technical systems

This title of this chapter contains the term availability and formulates the reasonable goal of increasing the same. In order to provide a clear understanding of measuring the utilisation rate of a technical installation it is useful to introduce some standard definitions of the most important terms:

The availability of a technical system is often measured by using the definitions of the VDI 3423 [2] as released by the Association of German Engineers (VDI), where the availability of a technical system is defined as shown in the following relation:

(Total working hours of evaluation

Availability = period-Down time in evaluation period)

(Total working hours of evaluation period)⇥(1)

However for a practical evaluation of the utilisation of AF feeding installations, the overall down time needs to be separated in scheduled and unscheduled stops, since a scheduled down time, e.g. during a periodical maintenance period should not affect the measured availability.

For this reason the definition of the inherent Availability (Ai), which can be considered as the steady-state availability after the initial commissioning process and the typical adaption period are successfully completed.

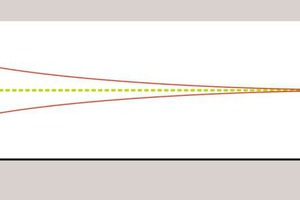

So if the availability is defined as a time-dependent function A(t) (often referred to as the instantaneous availability), as shown in Figure 2, the steady-state availability (see [3]) can be defined as

A(`) = limt➝` A(t)⇥(2)

It is obvious, the exponential nature of A(t) after the initial commissioning process can contain either a negative or positive slope, since the negative effects of an initial instability during the adaption process and the benefits from a complete new installation can be combined in either directions.

However, since this definition is quite a difficult measure for practical considerations, in most cases the definition presented e.g. in [4] is more useful, since it describes the availability as a function of the mean-time-between-failures (MTBF) and the mean-time-to-repair (MTTR). The exact definition of the inherent availability Ai can be defined as

Ai = MTBF

MTBF + MTTR⇥(3)

In this context it should be mentioned, that the given definition is used for complex technical systems, where the availability cannot be defined based on a single component. For single components a definition based on the mean-time-to-failure (MTTF) is a more common representation.

This measure does not contain down times for administrative, logistic or preventive maintenance reasons and is therefore a good measure to evaluate the overall systems reliability. So it can be concluded that the availability can be increased by either increasing the MTBF or decreasing the MTTR. While the MTBF depends mainly on adequate engineering decisions (e.g. usage of wear resistant materials or using high quality technical entities) and reasonable pre-active service actions, the MTTR value is influenced by more complex factors, such as the training of the service personnel, the accessibility of the different system components or the usability of the software components. Thus, even if the definition from equation 3 is quite a simple relation, it need to be considered also here, that the MTTR and MTBF values should only be considered to be constant, once the steady-state is reached.

It can be found, that the smart usage of remote access and maintenance solutions can help to reduce the later value drastically. Typical solutions are described here based on metering devices for AFs, as introduced in the subsequent section.

3 High precision dosing systems

for alternative fuels

If the SCC concept is used as a guideline for typical AF feeding installations, it is quite obvious, that the metering device can be considered as one of the most critical ones within the whole conveying line, since the accurate and reliable dosing of AFs is crucial for the combustion process. In this context it needs to be stated, that for a dosing system it is not just important that typical downtimes, where the installation is not in operation, can be avoided, but furthermore the dosing accuracy needs to be reliably within the given specification.

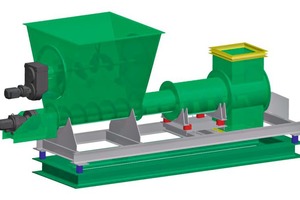

Di Matteo offers three different kind of gravimetric dosing devices for their installations: differential dosing setups for discontinuous dosing setups (e.g. for silo discharge systems), classical belt weighers (ODM-GraviScale) and the innovative and award-winning tubular weigh feeder, the ODM-WeighTube. Especially the introduction of the latter in 2011 was an important step towards a long-term stable and high precision dosing system, due to its unique design as a completely closed system, where the weighing measurement systems (load cells) are completely separated from the bulk-material, as described in [5] and shown in Figure 3. From past experiences with installations for a great variety of applications, it can be concluded today that these engineering decisions help a lot to increase the MTBF measure if compared to classical metering devices.

In terms of increasing the availability of the overall system, the mechanical platform is only one aspect, which should be considered. This is specifically important since most conventional dosing systems are only available with dedicated controllers, which use in most cases proprietary hard- and software modules.

Thus, for the service and maintenance personnel within the plants these controllers are black-boxes and in the case of a problem with the dosing accuracy or a general error it is very difficult to fully understand the inner reasons for the malfunction. As a logical consequence it is also difficult to resolve the problem without the help of a service technician from the manufacturer of the device, which is leading to much longer downtimes (MTTR increases).

For this reason the automation specialists at Di Matteo developed a full modular hardware and software concept for the realisation of gravimetric dosing controllers, the ODM-GravitAS control system. This concept implements a modular hardware approach, which is only based on off-the-shelf products from widely accepted vendors of automation products. Furthermore the software implementation is based on common open standards for PLC languages, such as IEC 61131-3, or quasi-industrial PLC standard language sets (e.g. STEP7 from Siemens). The complete concept of the system is described in more detail in [6]. Due to the fact that service personnel can identify and resolve problems by using the tools and systems they are already used to, the MTTR can be drastically decreased. Today Di Matteo is using the same controller concept for all its gravimetric machines and applications, as shown in Figure 4.

Furthermore it is possible to include the remote access option (GravitAS-RA) to all installations in order to provide the possibility to immediately connect to the control system from any possible location in the world. Typical architectures for the realisation of remote access schemes are introduced in the following section.

4 Remote access and maintenance

as a tool for increasing the availability

As mentioned in section 2, the overall availability of the system can be increased if (i), MTBF can be increased or (ii), the MTTR can be decreased or (iii). Both effects can be achieved in parallel. Towards the realisation of these effects, the introduction of remote maintenance and access modules can play an important part.

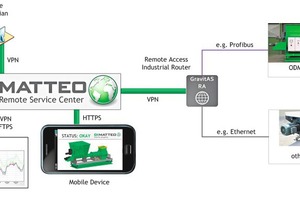

For years Di Matteo has been offering modular concepts for the integration of remote access solutions within their control and automation systems of complete installations. One prominent example is the GravitAS-RA remote access module, which is offered as an optional module within the modular GravitAS control system (see [7]) for gravimetric high precision dosing platforms, such as the ODM-WeighTube. The ODM-GravitAS RA remote access and maintenance solution is based on the integration of a GravitAS-RA industrial router within the control cabinet of the dosing device. The router is responsible for the management of the connection to the local PLC. For this Di Matteo offers units with various types of PLC interfaces (over 90 different drivers are included) in order to connect to all common PLC types and manufacturers. If the control system contains for example a Siemens S7-family PLC, the connection between GravitAS-RA and the PLC can be done by the multi-point interface (MPI), Profibus or ProfiNET, while for Allen-Bradley based control systems, an Ethernet-IP or DeviceNet communication would be more preferable, etc. The same variety of interfaces is also available for the connection of the module to the internet and can be achieved by providing a fixed network interface or the included WLAN modem by utilising an analogue or digital telephone line (analog, ISDN) or a mobile network (GSM, GPRS, EDGE, UMTS, LTE). In all cases the connection between the internet and the module is not continuously available, but will only be established by special control instructions (e.g. sent by text messages) sent by Di Matteo automation technicians or by request from the plant. By this the costs for the connection can be reduced and furthermore a non-existing connection is the most efficient security guideline to follow.

However, speaking of security, it is important to mention, that the connection between the remote technician and the module will be achieved by using a secure virtual private network (VPN) connection and integrated firewalls and this even in a double sense, since within the Di Matteo remote access architecture, there will never be a direct connection between a remote service PC and the PLC itself.

As shown in Figure 5, a direct VPN connection between the GravitAS RA module in the plant and the final application will only be established from the Di Matteo Remote Service Center, which is a dedicated server platform. All end user applications will only communicate with the remote service center and never directly with the PLC in order to guarantee a maximum security level.

The typical devices which communicate with the machines are also shown in Figure 5, where the range of interactivity varies from full access to the program for service technicians, archiving for databases and only observation for visualisation. These three levels of access also represent the typical possibilities for the enhancement of the machines availability.

Let us assume the technical system is actually malfunctioning and for this reason is not operational. For this reason a maintenance action needs to be executed. As defined in [8], those maintenance actions need to be associated with a certain amount of time which it takes to complete the necessary actions. This time will be defined as the downtime (Td) and can be influenced by various different factors, such as the physical characteristics of the system, spare part availability, repair crew availability, human factors, environmental factors, etc. If this is considered td can be divided into two categories based on these factors:

Waiting Downtime (tdw)

This is the time during which the equipment is not in operation but also not yet undergoing any kind of repair or service. This could be due to the time it takes for replacement parts to be shipped, administrative processing time, etc.

Active Downtime (tda)

tda is the time it actually takes to bring the machine back to a status where it is operational. So this value is the actual time, where service personnel are actively working on the machine.

By this the overall downtime can be defined as the sum of both components:

td = tdw + tda⇥(4)

If these times are measured for a number of interventions, the typical MTTR of an installation can be estimated by means of statistical modelling. The MTTR can then be interpreted as a measurement on how well an organisation can respond to a problem with a given machine.

By considering now the existence of a remote access module, it can be shown that both, the active and the waiting downtime can be immensely reduced if the platform is used in a reasonable manner. The most obvious time savings are clearly associated with the fact that specialised personnel from either the supplier or a different plant do not need to travel, since the GravitAS-RA module gives full control of the PLC and all problems related to software issues can easily be solved. Furthermore, even if a mechanical problem is the reason for the downtime, the waiting time can be reduced, because the system allows the technician to do an in-depth analysis of the problem by using current and archived process values. From the past experience of Di Matteo this led in numerous occasions to a situation, where the service technicians in the plant were able to resolve the problem on their own based on detailed how-to-do descriptions delivered based on a prior analysis of data from the remote access module. However, even if a spare part is needed, it provides the possibility that the service technician can bring the correct parts directly with him as soon as it is decided that a visit is necessary. All of the aforementioned examples describe only the advantages during the corrective maintenance, which can be defined as all actions taken to restore a failed system back to its operational status. For an increased availability of the system, all factors which can be grouped under the term preventive maintenance need to be also considered. A short case study is shown in the next section.

5 Pro-active maintenance –

a worthy glance into the crystal ball

Preventive maintenance can be defined as the practice of replacing components or subsystems of a technical installation before they fail in order to promote continuous system operation, or even the avoidance of a replacement by a proactive action. By this it is possible to guarantee a higher availability of the technical system when it is important for production and typical repairs can be shifted to periodical maintenance intervals or times when the system is scheduled to be down.

In cement plants preventive maintenance is already used, especially for the continuous monitoring and pro-active replacement of mechanical elements. However, the determination of the system status from actual measurements and data analysis is not utilised to its full potential. A typical application of pro-active maintenance for a dosing application would contain e.g. the automatic analysis of the integrated weighing system based on a data analysis of historic data.

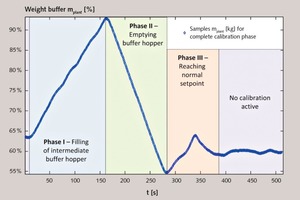

The ODM-GravitAS control system for the ODM-WeighTube implements an automatic calibration routine, which provides the possibility to estimate properties of the dosed bulk material and automatically adapt the controller parameters in such a way that the dosing accuracy remains stable over time. During this automatic calibration routine the intermediate buffer hopper of the ODM-WeighTube is filled to a certain maximum in a first stage of operation. Within the second phase the buffer hopper is emptied by normal dosing operation (and parallel stopped feed of material to the buffer) up to a predefined minimum buffer weight. From the resulting difference in mass (Δm) and the corresponding expired time (Δt), the actual control parameters of the continuous dosing controller are automatically adapted. A typical calibration process, with its three phases, is shown in Figure 7, where the actual buffer weight mplant [kg] is visualised over time.

To avoid possible undesired influences, all controller parameters are checked for plausibility based on a probabilistic analysis of former calibration cycles, before they become active in the system. This statistical analysis can be used in order to provide an automatic notification of the plants maintenance department, that the weighing system of the dosing unit needs to be checked next time when it is not operational.

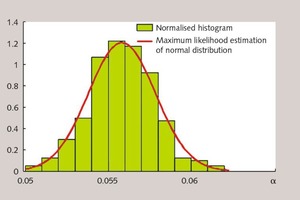

This can be achieved by modelling the controller parameter based on a Gaussian probability density function. For this a control parameter a, which will be automatically adapted during a calibration cycle, will be observed. Since a is slightly adapted during each calibration, it can be modelled as a set of n measurements [a1 … an]. These measurements are assumed to follow the Gaussian (or normal) distribution, as defined by the following equation, where μ depicts the mean value of a and s the corresponding standard deviation:

(a – m)2

f (a|m,s) = 1 e – 2 ? s2⇥(5)

s √2}? p

Due to the overall stability of the system the standard deviation of the Gaussian bell curve is typically quite small and can be interpreted as an indicator of a good condition of the weighing system. If the standard deviation is increasing from one point in time it can be automatically analysed in order to generate an indicator for the plant when the load cells should be checked by the service personnel.

Figure 7 shows a typical discrete normalised histogram of a and the corresponding Gaussian distribution as estimated by using the maximum-likelihood estimation (MLE) method, as described in [9]. It is clearly observable that the assumption of a Gaussian process is quite reasonable and furthermore the detection of abnormalities based on the estimated standard deviation is easy to be implemented by considering the sample variance s², based on n discrete measurements of a and the corresponding sample mean a−:

s2 = 1 ? ∑ni = 1 [ai – a− ]2⇥(6)

n – 1

The evaluation of these measurements can be realised within the PLC or the GravitAS RA remote access module and the actual condition can be visualised as a web-based service in the Di Matteo Remote Access Center. Using this service technicians can look at this data from their working places all over the world and/or by mobile devices used on site. Furthermore the system is able to generate automated messages which are transferred by mail or text message to the maintenance personnel in the plant. These messages can even include detailled information about the pro-active actions which should be executed. Figure 8 shows a typical example of the interactive display of plant information on a mobile device. The information is loaded in real-time from the Di Matteo Remote Access Center by using HTTPS protocol, while the actual plant state is automatically updated by the server over a secure VPN connection to the GravitAS-RA remote access module mounted in the control cabinet in the plant.

6 Conclusion

The implementation of a remote access module within actual installations for AF dosing and feeding provides numerous possibilities for increasing the overall availability of the installation. If the availability is defined as a function of the mean-time-between-failures (MTBF) and the mean-time-to-repair (MTTR), it was shown that both indicators can be positively influenced by the reasonable usage of the services included within a remote access module. For this, the example of the actual high precision AF dosing devices was used, where especially the innovative tubular weigh feeder ODM-WeighTube was used as a case study. In this context a possible example for the integration of preventive maintenance measures was described. Due to modern connection architectures based on virtual private networks (VPNs) and the inclusion of the Di Matteo Remote Service Center as a natural firewall between the end-user and the machine itself, security concerns are no longer justified.

The smart integration of a remote access strategy can help to increase the availability of an installation drastically and should be common sense for all planners of such machines. The relatively low integration costs are compensated in most cases during the first usage of the remote access due to the enormous savings in travel and personnel costs. In this context it should be mentioned that small scale solutions can be also easily integrated within existing installations.

Di Matteo will further develop their actual applications in that field and preventive maintenance solutions for all parts of an installation are already available.

//www.dimatteo.de" target="_blank" >www.dimatteo.de:www.dimatteo.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.