Successful expansion

A reliable, trouble-free and highly precise dosing of bulk materials is a key factor in complex processes, such as cement production, in order to achieve a continuous and cost efficient production. This was valid in the past, and has become even more important in today’s highly automated processes.

Particularly, in the past the focus was on the dosing of solid alternative fuels in a a reliable, trouble-free and precise manner, for example RDF for the calciner, SRF for the main burner, biomass, meat and bone meal (MBM), impregnated saw dust or dried sewage sludge. The available technical...

A reliable, trouble-free and highly precise dosing of bulk materials is a key factor in complex processes, such as cement production, in order to achieve a continuous and cost efficient production. This was valid in the past, and has become even more important in today’s highly automated processes.

Particularly, in the past the focus was on the dosing of solid alternative fuels in a a reliable, trouble-free and precise manner, for example RDF for the calciner, SRF for the main burner, biomass, meat and bone meal (MBM), impregnated saw dust or dried sewage sludge. The available technical solutions had many disadvantages, which could not fulfil all of the stringent requirements and therefore were not acceptable for the application.

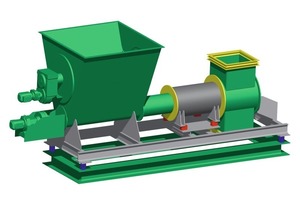

In response to this, Di Matteo, well known as a leading company in the field of handling bulk material and alternative solid fuels, began development of a dosing system, suitable of fulfilling all of the high requirements of a process dosing system. Over the course of five years, with the experiences and knowledge of more than 45 years in the cement industry as well as in the heavy-duty-industry, a revolutionary and innovative award-winning dosing system, WeighTUBE®, was developed (Fig. 1).

Since the official market introduction at the beginning of 2012 [1, 2, 3], more than 45 units have been established worldwide in what is known as a conservative cement industry. Meanwhile, this unique and patented dosing system, WeighTUBE®, is manufactured in series (Fig. 2).

Di Matteo is not only an engineering company, but also an OEM with a highly qualified “Made-in-Germany” production. All products are designed and manufactured in one of the three production plants in Germany located in Beckum and Ilmenau (Fig. 3).

Originally, the WeighTUBE® was developed for dosing all types of solid alternative fuels as mentioned above. But in most of the cases, alternative solid fuels are pre-processed industrial and commercial solid waste; quality controlled with a high calorific value similar to lignite. These are comminuted, granulated or pelletized to different grain sizes, and fibrous or fluffy solid fuels which are difficult for dosing. The material acts unstable, builds bridges and blockages or suddenly change its bulky material characteristics i.e. varying from very low to high bulk density. The moisture content and the particle size are dependent on the suppliers due to a different prehistory of treating.

Consequently, Di Matteo offers, at its groups testing facility, analysis and operational runs of the desired bulk materials. Depending on the grain size and its density, one or two large bags are required for the testing.

As mentioned above, an industrially applicable dosing system has to fulfil stringent requirements including robustness yet high accuracy, a large control range, short response times, good reproducibility of parameters, extraordinary reliability, and a high level of automation.

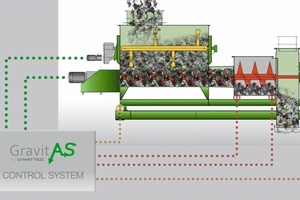

The scale works by feeding the solid alternative fuels into the pre-hopper, where the material is agitated in order to guarantee a continuous volume and feeding level (Fig. 4). A through shaft doses the material volumetrically through a tube into the freely suspended weighing section. The support for the pre-hopper, screw and rotary valve is placed on its own load cells, while the weighing section is separated. By applying this principle, the control system registers the quantity and weight per time unit.

Currently, gravimetric dosing systems are equipped to continuously weigh a streaming bulk material and show a higher-level of control for regulating the mass flow rate to a defined set-point. Further criteria for a gravimetric dosing system especially for alternative solid fuels are:

insensitivity against harmful impurities

high short-term and long-term precision (robustness)

tenure of an internal calibration system, best performed automatically and online during operation

comprehensive system monitoring

high operational reliability

simple mechanical design for easy maintenance

identical dosing consistency as with conventional fuels

compact dimensions

With the WeighTUBE®, all these criteria can be achieved successfully. One of the first devices installed for dosing solid alternative fuels has been in operation in a cement for more than four years. The predecessor equipment has been replaced and a dust free environment has been achieved.

In the meantime, the WeighTUBE® family (Fig. 5) has been extended to handle other bulky materials like powdered coal or mineral materials such as ground cement, raw meal, clinker, slag, or fly ash. Consequently, each requirement can be fulfilled by an optimum design and size of the WeighTUBE®. Establishing it for an efficient gravimetric dosing has been a milestone for feeding and dosaging.

The series, originally devoted to the dosing of alternative solid fuels, has been proven in daily rough practice and represents a successful expansion to the range of the WeighTUBE® line. Now, mineral materials such as raw meal, or coal and the huge variety of alternative solid fuels can be fed precisely and a continuously running and cost saving process is guaranteed. //www.dimatteo.de" target="_blank" >www.dimatteo.de:www.dimatteo.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.