In-line calciner conversion

at LafargeHolcim Mannersdorf

With the current trend of maximizing the substitution rates of alternative fuels while emission regulations are becoming more restricted, the cement industry is facing various challenges. While for in-line calciner systems the use of solid alternative fuels is well proven, separate-line calciners are in many cases limited to a great extent as regards the use of this fuel. LafargeHolcim in Mannersdorf/Austria has set a goal for maximizing solid alternative fuel rates with simultaneous reduction of CO and NOX emissions. To reach this target a conversion from the existing separate-line calciner to an in-line calciner for the kiln line in Mannersdorf has been done, considering the restrictions of the existing system, aiming at 100 % solid alternative fuel utilization in the calciner and reaching lower emission values. In addition, the increase of preheater efficiency was also addressed in this project. A TEC Production and services acted for this as supplier for technology and engineering as well as for equipment supply and the necessary site works for installation on a turn-key basis.

1 Introduction

Due to the high demand of thermal energy for clinker production, fuel economics as well as emissions are a central topic for efficient and sustainable clinker production [1].

Using alternative fuels offers kiln operators the possibility to reduce emissions as well as to be more competitive on the market due to the cost savings regarding fuel costs of fossil fuels [2].

The utilization of alternative fuels, however, comes with several challenges for the process with disadvantages such as insufficient burn-out which might lead to increased emission levels and impact on the production...

1 Introduction

Due to the high demand of thermal energy for clinker production, fuel economics as well as emissions are a central topic for efficient and sustainable clinker production [1].

Using alternative fuels offers kiln operators the possibility to reduce emissions as well as to be more competitive on the market due to the cost savings regarding fuel costs of fossil fuels [2].

The utilization of alternative fuels, however, comes with several challenges for the process with disadvantages such as insufficient burn-out which might lead to increased emission levels and impact on the production capacity. Moreover impurities in the fuels can lead to increased internal cycles of chlorine and other volatile components.

While using SAF (solid alternative fuels) in the main burner a certain minimum fuel quality is needed to maintain a stable sintering zone, the fuel used in a calciner can allow a larger range in heating value, particle size, etc. This leads to the conclusion that calciner combustion is the more preferable way to use low quality solid alternative fuels.

To allow a maximum rate of SAF in the calciner there are also here certain challenges to tackle to keep the emissions low and production at the nominal load. Separate-line calciners (SLC) have here a significant drawback due to their sensitiveness to larger fuel particles compared to in-line calciners (ILC). Also for emissions the ILC type offers advantages to treat the kiln gas with optimized combustion control.

In the applied case for the kiln line at LafargeHolcim Mannersdorf/Austria the system was equipped with a comparably small separate-line calciner which was limited for SAF use. Therefore the calciner system was converted to an in-line calciner system developed and installed by A TEC Production & Services GmbH, an Austrian-based pyroprocessing specialist in 2016/2017.

2 Clinker production at LafargeHolcim

Mannersdorf and situation before modification

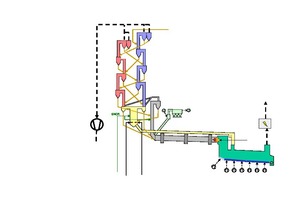

LafargeHolcim operates a grey cement kiln line in Mannersdorf/Austria, which was commissioned in 1984. The kiln line has a production capacity of 2550 t/d marking Austria’s largest cement plant. The preheater is a two-string system with a separate-line calciner. The flowsheet can be seen in Figure 1. The calciner has a limited gas residence time of approx. 1.5 s, which means that utilization of coarse solid alternative fuel is limited. The preheater/precalciner system is designed according to the so-called “Pasec” system, a system from the former Voest-Alpine Industrieanlagenbau GmbH, which has a special way of guiding the meal through the two preheater strings: The whole amount of meal is crisscrossing between kiln string and calciner string [3]. For NOX reduction the plant is equipped with the first semi-dust SCR system, installed in 2012 [4]. Alternative fuels (SAF and used oil) have been used in this configuration to a maximum TSR (thermal substitution rate) of 65 %, keeping in mind that for the calciner the required SAF quality was main burner material with a max. particle size (2D) of 30 mm. The preheater and the small SL precalciner, which is integrated in the preheater structure, before modification, can be seen in Figure 2.

3 Calciners and solid alternative fuels

It has turned out that there is a significant difference between in-line calciners (ILC) and separate-line calciners (SLC) when speaking of high substitution rates of SAF in calciners. Mostly ILC systems are considered due to the arrangement of the systems and the specification of the SAF.

Solid alternative fuel is in many cases the high calorific fraction of municipal solid waste (MSW) or industrial waste, shredded down to a size which can be burned in the calciner. In many cases particle sizes between 30 and 120 mm are used here. Due to the origin and inhomogeneity of SAF, there is a high possibility that some single larger, or heavier, particles are in the fuel stream. Fundamental information about plastics combustion for cement plant applications can be found in the study byA. Díez Callau [5].

For in-line calciners, the kiln gas enters the calciner at the bottom where also the tertiary combustion air is added, followed by fuel and meal inlet. This means the complete gas flow (kiln gas and tertiary air) has to pass the calciner. Therefore ILC systems are built larger than SLC systems. However, using SAF in the Calciner, ILC systems offer the advantage of not being sensitive to SAF particles which are too large or too heavy to be fluidized and safely transported with the mix of kiln gas and tertiary air. If such a particle enters the calciner, it is either stopped at the orifice until it is burned small enough or it even drops through the orifice into the kiln inlet chamber. Those particles can then burn in the kiln inlet without causing any negative impact on the operation of the system (considering that the majority of the SAF is transported through the calciner).

Separate-line calciners are fed only with the tertiary air at the bottom where fuels and meal are introduced. After the completed combustion and calcination in the SLC, the gas from the calciner outlet and the kiln are either joined and pass the preheater together or they stay separate and flow through separate preheater systems. When firing SAF, the main disadvantage is that the system is sensitive to larger and heavier particles which cannot be transported via the gas flow. Such particles drop into the tertiary air duct causing blockages there and limitations of the tertiary air gas flow [6].

4 Project development and project description

Due to the reasons explained in the previous section, the plant was very much limited with SAF utilization in the existing calciner as the gas residence time was too low and the very fine shredded waste required for the SLC concept. A consequence of the SAF utilization was a risk of CO peaks that could disable the ESP before the SCR catalyst.

Summing up the current situation, the project aims were:

Conversion from a separate-line calciner to in-line calciner

Firing of 100 % SAF at the calciner

SAF particle size up to 80 mm (2D)

Reduction of CO

Efficiency increase of the preheater system

To reach the aims, the following concept was developed:

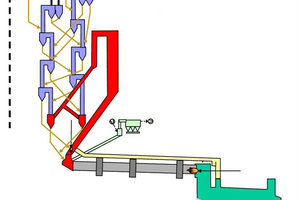

1. The new in-line calciner could not be placed inside the existing building; therefore it was placed in front of the existing preheater tower in a new steel structure. To implement the new calciner in the existing process, the complete part of the lower preheater tower was re-designed, which included both bottom stage cyclones (of the former kiln and calciner string), the meal pipes from both cyclones at stage 4 and 5 (to calciner and kiln inlet), the fuel feeding and tertiary air duct as well as all the required structural modifications to the existing preheater tower. The structure of the new calciner reaches a height of approx. 80 m. At the top (gooseneck or calciner bend) of the calciner the A TEC Post Combustion Chamber is implemented. The existing Cl-bypass system has been adapted to fit to the new system. The modifications and the overall concept is shown in the 3D model in Figure 3, the realized overview of the calciner in the new steel structure is shown in Figure 4.

2. To use 100 % SAF as fuel in the calciner (also as control fuel for the process) with a particle size of up to 80 mm (2D), the residence time of the gases in the calciner at nominal load reach 7 s. A focus on stable flow pattern ensures a constant transport of material and fuel keeping the process well controllable.

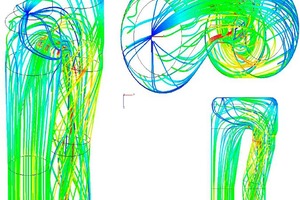

3. The reduction of emissions is also an essential factor when changing the concept from SLC to ILC. Beside the reduction of CO, also NOX values are reduced due to the reducing atmosphere in the lower part of the calciner where the fuel is fed. For CO the important aspect is the gas residence time and the application of the A TEC Post Combustion Chamber (PCC) which is an essential part of the concept to reach the target. The PCC is a special design of the calciner top: In the upward stream of the PCC the diameter is increased in order to increase the residence time for particles which are not yet fully burned (Figure 5). The entrance to the downstream calciner section is designed eccentrically to create turbulence and a mixing effect as shown in the flow pattern in Figure 6. A top view of the PCC in the Mannersdorf plant is shown in Figure 7. This leads to the effect that unburned matter and gases (CO, etc.) are mixed effectively with unused combustion air and complete their combustion before entering the preheater cyclones.

Beside the calciner installation the focus was also on improving the efficiency of the preheater system especially for dust losses at the top stage. This was done by modifications of the top stage cyclones itself as well as the change of the “Pasec” meal introduction from a single introduction point of 100 % of the raw meal to one of the two strings to a splitted inlet to both top stages. Already this reduced the top stage losses about 50 % as only 100 % of the raw meal has to pass both top stages instead of 200 %. Subsequently also the meal routing to cyclone stages 2 were adapted. For better understanding the flowsheet before (Figure 1) and after modification (Figure 8) can be compared.

A TEC Production and Services GmbH was the main contractor for the project on a mechanical EPC basis. A TEC was responsible for the complete design, dismantling, manufacturing and erection works of the steel structure and equipment including the necessary site works and services.

The site works for mechanical erection in Mannersdorf started in September 2016 with the erection of the steel structure (Figures 9 and 10) for the new calciner followed by the calciner installation. Both were finished in December 2016. During kiln stop the old calciner was dismantled, the adaptions on the bottom stage cyclones and the meal routing was done to allow the connection of the calciner to the system. This was realized within one kiln stop (meal off – meal on) of nine weeks.

5 Results

Successful restart and commissioning was done in March 2017 according to the project schedule. The first operational results confirmed the process values previously calculated. Summing up, the observed differences were:

Operation achieved with 100 % SAF as control fuel at the calciner (13-15 t/h SAF). In combination with SAF and LAF (liquid alternative fuels) at the main burner, the plant is operated with a TSR of up to 90 %

Dust losses at the top stage were reduced approx. 50 %

CO emissions with 100 % SAF at calciner are typically below 500 mg/Nm³

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.