High time for high temperatures

ThyssenKrupp Industrial Solutions AG (TKIS) has become a major player in the field of pyroprocessing minerals. Limestone, gypsum, dolomite, magnesite (natural as filter cake or flotation concentrate) and bauxite are those precious raw materials for which TKIS designs and engineers kilns and furnaces.

1 Introduction

In today’s market not only energy efficiency, sustainability and innovation are mutual objectives, but also reliable aggregates to perform for decades. With rising energy costs and the desire to maintain a clean environment for future generations, TKIS from Beckum, Germany strives to provide the best equipment, which applies the latest developments in technology for the best use of mineral resources. Thus, everybody always has to be ready to find new approaches. No matter how exotic und unusual the material – with its range of products any company can always find a way to process...

1 Introduction

In today’s market not only energy efficiency, sustainability and innovation are mutual objectives, but also reliable aggregates to perform for decades. With rising energy costs and the desire to maintain a clean environment for future generations, TKIS from Beckum, Germany strives to provide the best equipment, which applies the latest developments in technology for the best use of mineral resources. Thus, everybody always has to be ready to find new approaches. No matter how exotic und unusual the material – with its range of products any company can always find a way to process it – as TKIS does. Energy efficiency, state-of-the-art equipment, reliability, sustainability, innovation – are not just empty phrases for them.

2 Thermal process

TKIS’s vast range of products suitable for different types of feed material with grain sizes of between < 20 µm and 200 mm covers any thermal process from drying and calcining to sintering starting at temperatures of around 100 °C up to 2300 °C. Whenever there is a challenging task to accomplish with respect to unusual raw material characteristics or special product quality, engineers work closely together with the R&D department to present a solution for the best process application and highest efficiency values.

Specialists accompany the customers at every step of the journey, from the planning stage, process consultation and optimization to the supervision of construction and commissioning. When it comes to choosing the appropriate aggregate and equipment for the process, not only the desired product quality has to be considered but also characteristics of the feed material. Apart from standard examinations, shatter and decrepitation tests are performed to determine the suitability for shaft application, drum tests in the case of rotary kilns.

3 Types

Calcination is the master thermal treatment method for a broad range of industrial minerals with the aim to remove chemically bound carbon dioxide at elevated temperatures resulting in the change of the physical properties of the minerals. TKIS supplies an aggregate or an integrated process for any calcination process. Apart from the MAERZ® Parallel-Flow-Regenerative shaft kiln (PFR), the Annular Shaft Kiln (ASK) and the Multiple Hearth Furnace (MULTIPOL®, Fig. 5 and Fig. 6) can be used for the calcination of limestone and dolomite (Tab. 1) . The ASK and MULTIPOL® will be described at a later point by means of two specific projects.

3.1 Rotary kiln and MSP

The classic among the calcination aggregates for this application is the well-known rotary kiln, characterized by its high flexibility in throughput and firing conditions. It can be equipped with a Flash Calcining System (POLCAL®) in case of fine grain material or a Multiple Shaft Preheater (MSP) for lumpy material with the advantage of increasing its specific production load, improving energy efficiency and making use of fossil fuels with high sulphur contents.

The MSP uses the counterflow principle for heat transfer in a packed bed within a modular design: Hot kiln exhaust gas is sucked through separate shaft modules, thus enabling a controllable heat transfer. Since the bulk of hot limestone/dolomite functions as a packed bed filter in the preheater, dust and gaseous emissions are retained. In contrast to the operation of a long rotary kiln, cycles of impurities are generated here, which induce an increased contamination of the kiln system and thus the lime/dolime product. To achieve the required product quality, TKIS offers a sulphur bypass that reduces the sulphur content of certain fossil fuels. The key component of the sulphur bypass is a roller grate that serves as a screening device separating the contaminant laden dust from the product in such a way that the product quality meets the customer’s requirements.

3.2 Gas suspension calciner

Another option, particularly for the calcination of limestone and the dehydration of gypsum (Tab. 1), is the Gas Suspension Calciner POLCAL® for fine grain material. POLCAL® systems have several cyclone stages for drying and preheating the material as well as a calciner for the main thermal treatment. One or more cooling cyclones are installed to reduce the temperature of the treated product and return energy to the thermal process as secondary air. The individual cyclone stages are interconnected by gas and material ducts. The modular arrangement and the variety of cyclone types to be chosen lead to an utmost flexibility in process engineering providing for a tailor-made solution in concordance with the customer’s requirements. By varying the temperature and/or residence time in a conditioning drum installed downstream of the calciner system, the degree of reactivity of the burnt material can easily be adjusted. In case of high moisture contents it is possible to install a flash drying system upstream.

For the calcination of dolomite and magnesite the rotary kiln, MSP and Multiple Hearth Furnace MULTIPOL® are applicable.

3.3 High temperature calcination

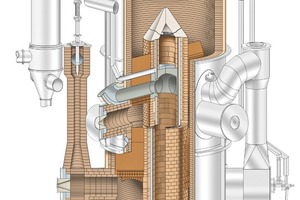

Upstream of production of high quality refractory material temperatures of up to 2300 °C are needed to achieve a specific density and periclase crystal size. Here either the rotary kiln or the pressurized high temperature shaft kiln POLSINT® (Fig. 1) come on stage, the only two kiln types capable of producing dead burned magnesia or dolomite. Depending on the raw material characteristics, calcination and sintering in one step (direct sintering) it is possible to apply both kiln types. Each kiln has specific requirements regarding raw material characteristics. While the rotary kiln can digest particle sizes up to 50 mm and is capable of production rates up to 800 tons per day (depending on the material) POLSINT® requires more homogenous feed material and has a significantly lower throughput and energy consumption.

4 Recent projects

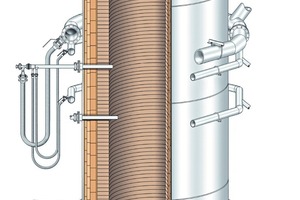

Two recent projects – limestone calcination in an ASK (Fig. 2) for Saudi Lime Limited and magnesite calcination in MULTIPOL® and sintering in POLSINT® for the Russian Magnezit Group – will give a more detailed overview of the equipment and the process.

4.1 Saudi Arabia

The Saudi Arabian ASK (Fig. 3) started production of lime for the Saudi LIME Industries Company, headquartered in Riyadh, Saudi Arabia with a capacity of 165 000 tpa in 2014. This is already the fifth kiln commissioned after more than forty years of a successful cooperation between TKIS and the Saudi LIME Industries Company.

4.1.1 ASK design

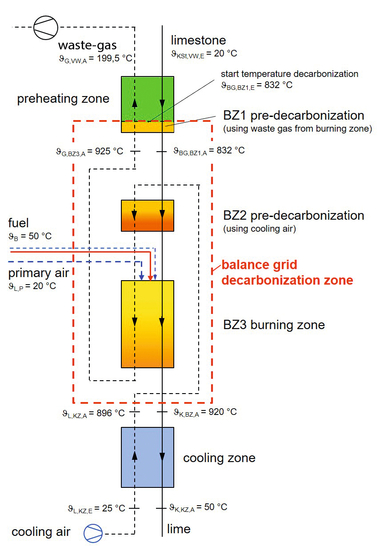

The centerpiece of the ASK is the kiln shaft which is formed by the lining of the kiln shell and the concentric inner cylinders. During the burning process the limestone passes three zones comprising the preheating zone, the burning zone and the cooling zone.

The ASK’s inner cylinder is formed by a suspended upper section, through which the exhaust gas required for heating the driving air is sucked to a heat-exchanger, and a standing lower section which has openings and channels for exhaust gas recirculation. The double-walled, refractory-lined steel casings of the upper and lower inner cylinders are air-cooled. The preheated air leaves the lower inner cylinder through cooling-air ducts inside the refractory bridges. The preheated air is collected in a ring manifold and re-fed as combustion air. The driving air drawn by the driving air blower is forced into the heat-exchanger, which is an energy efficient way to acquire energy from the exhaust gas. Coming from the heat exchanger the hot injector driving air passes into a ring conduit from which it is distributed to the injectors and is also used as atomizing air to the fuel oil burners.

In the upper combustion chambers the fuel is burnt with air deficiency. The incompletely burnt gases flowing out of the upper combustion chambers penetrate the heated bed underneath the bridges and meet the excess air coming from below, which is controlled to ensure complete fuel conversion at gentle heat up of the limestone material. As the calcination of the limestone in this burning zone has hardly even started, the post-combustion of the gases has no negative effect on the lime quality or the refractory lining.

Oil fired burners supply heat at two burner levels. In the lower combustion chambers the fuel oil is completely burnt out at excess air conditions before the gas enters the heated bulk of material. The gases flowing out of the lower combustion chambers divide into two streams, one of which is drawn downwards to form the co-current burning zone, while the other is drawn upwards through the countercurrent burning zone driven by the process fan.

4.1.2 ASK operating principle

The screened and weighed limestone is conveyed from the batch weighing system via a skip transport system to the kiln top, where it passes through a sluice system that also acts as an air seal to prevent false air from entering the system. The limestone is charged into the kiln by a rotating chute. The annular shaft kiln is operated at negative pressure and controlled by the master process fan.

The limestone entering the preheating zone is dried by the exhaust gas in countercurrent flow and preheated to calcination temperature. The exhaust gas emerging via a collecting chamber mingles with the exhaust gas stream from the heat exchanger before being delivered to a dedusting system by the process fan.

In the burning zone the kiln has two burner levels with four cylindrical combustion chambers each, which are placed symmetrically around the kiln shell, dividing this kiln segment into two burning zones working in countercurrent and co-current flow. The arrangement of the upper and lower combustion chambers as well as the recirculating gas inlets in the lower inner cylinder ensures a uniform gas distribution over the entire cross section of the annular shaft. While being drawn downwards in a co-current flow, the gas’ energy is constantly transferred to the limestone material being calcined. At the end of the co-current zone the gas is sucked into the inner cylinder together with the lime-cooling air by the injectors. The recirculating gas exits the inner cylinder outwards through the bridges and then is forced into the lower combustion chambers together with the injector driving air.

Just below the co-current flow zone the quick lime enters the cooling zone, where it transfers its heat to the lime-cooling air drawn by the process fan. At the end of the cooling zone the quick lime is discharged from the discharge table by a hydraulically operated ram system and falls into a hopper underneath the kiln shaft. A vibrating feeder empties the hopper discontinuously.

4.2 Russia

The world’s largest MULTIPOL® (Fig. 4, 5) started production in 2014. Russian refractory manufacturer JSC Kombinat Magnezit, headquartered in Moscow commissioned TKIS to design and engineer an 80 000 tpa DBM production plant with a MULTIPOL® for calcination as well as a POLSINT®, which are both the largest of its kind for the production of Dead Burned Magnesia (DBM) at the time. The process technology part comprises every step necessary, from calcination to grinding, briquetting, sintering and product cooling for the required two-step process.

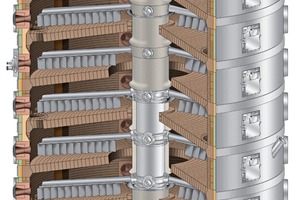

4.2.1 MULTIPOL® operating principle

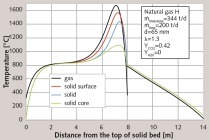

In the first process step raw magnesite is fed to the first calciner hearth (Fig. 6) of the MULTIPOL® by means of a belt/bucket elevator conveying system. The MULTIPOL® 78-19 contains 19 hearths of which the top five provide heat exchange between the off-gas and the natural magnesite feed for preheating purposes. The next 11 hearths are fired where the magnesite is calcined and the reactive product is formed. The bottom hearths provide product cooling. The movement of the material through the furnace is regulated by the rabble blades, supported by rabble arms (Fig. 7), which are attached to a frequency-controlled central rotating shaft. In order to withstand the high temperatures of up to 1050 °C, the rabbling system is cooled by air supplied by a cooling air fan.

The hearths are designed alternatively as “OUT”-hearths and “IN”-hearths. Feed to the top hearth is at the center. The material is rabbled spirally across the hearth to the periphery and drops to hearth No. 2 on the outside perimeter. On the 2nd hearth the material is rabbled back into the center and on the 3rd hearth it is rabbled to the periphery again. This pattern continues with final discharge from the bottom hearth. The reactivity of the product can be adjusted by regulating and varying the temperatures hearth by hearth.

The furnace in this project is fired with natural gas. In general liquid fuels like oil or diesel can be used. In this case nine hearths are equipped with four burners each, two hearths with just two burners. The preheated cooling air is recovered at the top of the center shaft to be used as combustion air for the burner system.

The residence time of the solids in the furnace is controlled by the center shaft speed, number of rabble arms, and type and arrangement of rabble blades.

The exhaust gas leaves the furnace at the top and is dedusted by a bag filter. The dust is either recycled into the MHF or stored in intermediate bins for further use.

In a second process step the product – caustic calcined magnesia (CCM) – is ground to the required grain size distribution and transported to the briquetting section, where the material is compacted to briquettes before being fed to the high temperature shaft kiln POLSINT®.

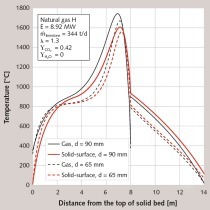

4.2.2 POLSINT® operating principle

POLSINT® (Fig. 8) consists of a cylindrical shell made of heat resistant steel and lined with high quality refractories in order to withstand temperatures of up to 2300 °C. The bottom section of the kiln is equipped with a discharge system with – in this project – a subsequent seal leg, which is basically a long duct. The material level in the seal leg is radiometrically controlled which defines the speed of the discharge table. The seal leg is kept full at all times to maintain the pressure inside the kiln. The production rate is controlled by the scale apron conveyor which is responsible for the throughput of the shaft kiln.

Primary air and fuel are injected into the combustion zone through water-cooled burner lances. Cooling air is introduced underneath the discharge table and moves upwards, retrieving heat from the product. The preheated cooling air is then used as secondary combustion air to provide the energy required for reaching the high operating temperature of up to 2300 °C which is needed to achieve the desired sinter density and large periclase crystal size.

There are two levels for the installation of burner lances to ensure a high flexibility regarding burning conditions and temperature profile. The hot exhaust gas flows upwards in counter current mode to the fresh feed material, preheats the CCM briquettes and is cooled down before being dedusted in the bag filter.

5 Conclusion

Engineering, procurement, construction – together with the international network of TKIS companies, the Beckum Group is able to exploit the full potential of a project, providing the customers with everything they need. Whether it’s a turnkey plant, plant sections, single machines, spare parts or technical support. Due to their vast range of products in the field of pyroprocessing, TKIS can offer kilns and equipment for any raw material requiring calcining, sintering, roasting, drying and cooling – adding value to minerals by applying the right temperature for the right period of time.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.