Gravimetric precision dosing in the cement industry

Gravimetric dosing systems are classified by their short-term and long-term accuracies. In this market review the cement process requirements for precision dosing are discussed and the latest technology trends are presented.

1 Introduction

Cement production requires accurate metering and dosing of bulk materials in each production step from raw material grinding to cement grinding and finally to cement mixing and blending. The better the accuracy of the short and long-term feed rate, the more stable are the processes, the better the processes can be optimized and the higher the quality of the clinker and cement. Take, for example, the raw meal dosing as an example, with relatively short processing time, less than 30 s, for the material in the preheater, where high dosing accuracy is necessary for a stable...

1 Introduction

Cement production requires accurate metering and dosing of bulk materials in each production step from raw material grinding to cement grinding and finally to cement mixing and blending. The better the accuracy of the short and long-term feed rate, the more stable are the processes, the better the processes can be optimized and the higher the quality of the clinker and cement. Take, for example, the raw meal dosing as an example, with relatively short processing time, less than 30 s, for the material in the preheater, where high dosing accuracy is necessary for a stable preheater operation. Or take the burner feeding, where dosing accuracy is essential to keep the calorific value constant for a stable preheater and kiln operation. These processes require dosing accuracies of ± 1 % or better.

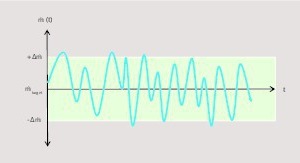

As a possible definition the term dosing accuracy can be described as the maximum permissible deviation Δm∙ of the actual metered feed rate m∙ (t) at a certain time t from the target set point m∙target (Figure 1). Accordingly the value of ± Δm∙ represents the tolerance range for the set point and the relative dosing accuracy ST can be written:

Δm∙

ST = ± ∙ 100 %

m∙target

The mean value m∙av of the feed rate is derived formally from the momentary value m∙ (t) by integration within the time span Δt = t2 – t1, according to:

t2

∫ m∙ (t) dt

t1

m∙av =

t2 – t1

Therefore, dosing accuracies should always be related to a time span and hence short-term and long-term dosing accuracies have to be differentiated. To keep the momentary value of the feed rate in the tolerance range, three basic requisites are a must: the feed rate needs to be measured, controlled and adjusted (by a controller). The only system which fulfills all these requirements is a metering or dosing system. In the cement industry these are almost always specialized engineered systems, which have to be designed according to the individual process requirements of the production steps. Thus it can be understood that there is no one design or piece of equipment, which fits all requirements.

2 Gravimetric dosing in the cement industry

2.1 Grinding systems

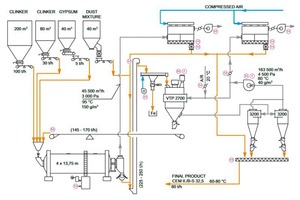

From a metering point of view raw material grinding and cement grinding are not very different, and the dosing systems look pretty much the same. But depending on the type of mill that is used the dosing system can look very different. There are four main mill types, including ball mills, vertical roller mills (VRM), high pressure grinding rollers (HPGR), horizontal mills or a combination thereof, especially combinations of HPGRs and ball mills [1]. Figure 2 shows a typical mill circuit scheme for a ball mill cement grinding system, with a number of feed points for clinker, gypsum and additives. In most of the ball mill grinding systems the feed rate for the fresh material is adjusted to the rate of the re-circulated grit from the mill to assure a constant total mill feed.

In the example fresh feed rate and recirculated rate are nearly the same, but there are enough examples, where the recirculated rate exceeds the fresh feed rate by a factor of 3 or more [2]. Accordingly, in ball mill grinding circuits the accuracy of the system depends very much on how the feed rate of the recirculated grit material is measured. In many cases for such closed systems impact flow meters are used with a measuring accuracy of ± 1.0 – 2.0 % for feed quantities of up to 1000 t/h. Less often, Coriolis mass flow meters with a higher accuracy of ± 0.5 % based on the nominal feed rate are preferred. Differences in the grindability and the fineness of the cement types affect the amount of the returned material. Therefore, the control concept for ball mill grinding systems uses the return rate as the main control parameter.

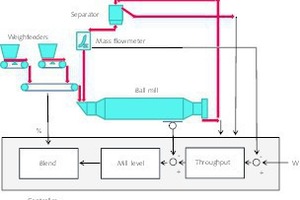

The mill control loop (Figure 3) generally has slow dynamics and the measurement of the finished product flow usually does not lead to any significant improvement in control quality. Stable flow rates of materials are achieved if the specific recirculating rate of the mill is preselected and the actual measured return flow rate of the fresh mill feed is adjusted to achieve a constant total mill feed. This also leads to a constant mill filling ratio, low mill vibration and a high grinding quality. Such a concept is also the basis for throughput optimization. For automatic and reliable mill starting the feed rates into the mill are mainly controlled by expert systems until the level of normal mill operation (closed loop operation) is achieved.

With VRMs the return rate is normally much lower (below 20 % of the mill feed), so that the grid return measurement even on conveyer belt scales with 1–2 measuring rollers can be used. The quantity of the fresh feed rate is precisely metered by weighbelt feeders (Figure 4), rotor weighfeeders or Coriolis flow meters in the case of fly ash and bypass return dust. The long-term accuracies of these types of equipment are mostly ± 1 % or better. The short-term accuracy plays practically no role in grinding systems. In cases of heavy mill loads for raw mills and cement grinding mills and especially when the raw materials are sticky, apron weighfeeders and other specialized systems have to be used. The dosing accuracy of apron feeders depends on the material load and is accurate to ± 1.0 – 3.0 %, because of the lower difference between net and gross weight of the system, when compared to belt weighfeeders.

Weighfeeders and rotor weighfeeders form a gravimetric dosing system via the use of metering hoppers or downstream calibration systems and their control systems. However, there are also examples of direct material discharge from the hopper where the “dosing” is done electronically with so-called mechatronic weighfeeder technology [3]. Such a system has the aim of locally measuring and processing the signals within the weighfeeder and using the measurement as a basis for direct transmission of the control commands to its own actuators. So the weighfeeder is able to monitor its own compliance to setpoint values via digital control. One module in such an independent system is a belt influence compensation to eliminate errors. The accuracy of such systems is given as ± 0.5 % or better.

2.2 Raw meal dosing

The capacity of single-string preheaters is limited by the maximum appropriate cyclone size, which today stands at about 9.0 m diameter and corresponds to a clinker production capacity of about 7500 t/d, with 6000 t/d as the maximum standard single-string capacity. For larger production lines up to 12 000 t/d double-string preheaters (Figure 5), sometimes with two raw meal homogenizing and dosing lines are used. But for cost reasons, the standard for large pyro-processing plants is one raw meal homogenizing line, one dosing system, one high-performance belt elevator and one raw meal splitter for the feeding of more than one preheater string. In most cases in such lines Coriolis mass flow meters are used which have an accuracy of up to ± 0.5 % related to the actual feed rate with a short-term feed constancy of ± 1.0 %. Alternatively rotor weighfeeders, impact flow meters or weighfeeders are used.

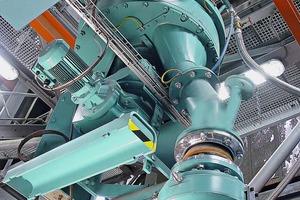

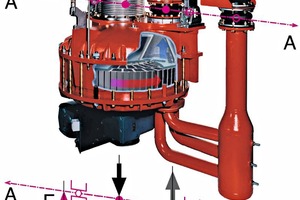

Advanced raw meal dosing systems allow throughputs of 1000 t/h (maximum 1250 m3/h), which will be enough even for the largest pyro-processing lines. Nevertheless, there is still an argument about which dosing system is the best and more importantly which one has a high dosing reliability and accuracy. Suppliers, who focus on rotor weighfeeders (Figure 6) argue about the lack of short-time accuracy of solid mass flow meters due to their retrospective control system [4]. Suppliers of Coriolis mass flow meters argue that these systems have developed in the last few years and that today Coriolis-based systems (Figure 7) with high short-term accuracy are available and that these systems have a non-sensitive measuring principle and allow for an inexpensive, simple plant integration.

The process of precise feeding of the raw meal into the preheater is one of the key points in stabilizing the clinker burning process and in optimizing stand-still times and costs. Principally the short residence times in the system of less than 30 s requires dosing systems which offer high short-term accuracy. The target today is a short-term feed constancy of better than ± 1.0 %, in a 30 s measurement under perfect conditions and a long-term accuracy of ± 0.5 %, with reference to the set point. The sensitivity of set-point adjustments can be better than ± 0.5 % over a large throughput range. However, the dosing accuracy for the raw meal dosing depends very much on the calibration system (Figure 8), a constant material flow, an almost constant material level in the pre-bin and short transport distances from the bin to the dosing system.

2.3 Pulverized fuel dosing

The residence time of pulverized fuels (coal, lignite, petcoke, etc.) in the pyroprocessing system is very short. A good indicator for the accuracy of the pulverized fuel dosing system is the oxygen level at the kiln exit. Poor dosing leads to larger fluctuations of the oxygen concentration. High short-term variations in the fuel dosing is also responsible for CO peaks. Accordingly, a good short-term accuracy for the dosing of pulverized fuels to the main burners and secondary burners is needed. Today, the targets for advanced dosing systems are ± 0.5 % for a 5 s measurement or ± 1.0 % for a 1 s measurement and adjustment ranges of 1:20 of the maximum feed rate. Such requirements can be fulfilled with either rotor weighfeeders (Figure 9) or Coriolis mass flow meters. However, there are differences in the design of this equipment from one supplier to the other, which also leads to differences in the dosing accuracy.

To achieve a highly reliable pulverized coal dosing it is recommended to decouple the dosing system from the fuel silo. This especially applies to extraction out of larger silos and to fuels with more difficult flowing behavior. Adequate solutions comprise calibration pre-bins/weighing hoppers with silo cone aeration or stirred discharge and extraction via rotary valves, starfeeders or flow control gates. There are several designs, which allow a dual or multiple feeding from a common pre-silo (Figure 10). But unlike raw meal dosing, each coal feeding line receives its own dosing system. A pulsation free pneumatic transport from the dosing system to the burner is very important and long transport distances and elbows should be avoided. However, often the transport distances to the burners exceed 100 m, which increases the dead time of the system and reduced dosing accuracy.

2.4 Alternative fuel dosing

Principally for the dosing of (secondary) alternative fuels the same high accuracy targets apply as for the (primary) pulverized fuels. However, the dosing flexibility becomes a major issue, when it comes to secondary fuels [5]. The greatest challenge is the diversity of alternative fuels. Consistency, bulk density, particle size, water content and calorific value are never the same. However, there are many attempts by the suppliers of such dosing systems to propagate a single technology, which fits all. References for a variety of materials are used as the proof for this thesis. From our point of view the “one-fits-all” approach is not right as different systems have their advantages and disadvantages according to the kind of alternative fuels used and the best dosing accuracy is not always required, but the systems should be reliable.

For alternative fuel dosing there are more dosing technologies on the market than for any other cement application. The main technologies which are used comprise specialized weighbelt feeders (Figure 11), rotor weighfeeders, Coriolis flow meters, screw weighfeeders and belt scales. The Hasler Gravit Light is a weighfeeder, which has a light material belt that is especially designed for alternative fuels with a maximum density of 300 kg/m3. Other leading weighfeeder suppliers such as Schenck, Merrick and Siemens use similar designs.

Screw weighfeeders are designed differently. The Weightube tubular screw conveyer (Figure 12) has an expanded cross-section for more accurate measuring and dosing. Another highlight of this dosing conveyor is that there is a linear relationship between the screw shaft speed and the screw flight pitch for accurate dosing [6]. The Multiflex screw weighfeeder (Figure 13) from Schenck Process is designed for alternative fuels with 50–700 kg/m3 and particle sizes up to 250 mm. Depending on the capacity, single and double trough versions are used. The integrated agitation principle creates a constant filling ratio of the screw. It comes in a dust-tight enclosed design with a pre-bin, which acts like an integrated loss-in-weight system that allows an on-stream calibration without additional equipment.

The Rotor Weighfeeder TRW -S/D (Figure 14) is also able to dose varying alternative fuels in a wide density range of 70–700 kg/m3. Very light materials such as plastics are measured in material layers of up to 500 mm in the feeder. For the processing of potentially-flammable materials such as sawdust and sewage sludge practically all suppliers offer an explosion proof design with ATEX certificate.

2.5 Cement mixing and blending

The design of the dosing system depends on the type of mixing: continuous or batch type mixing. For continuous feeding and blending the Coriolis mass flow meter can be used [7]. The Coriolis feeder by Schenck Process allows the simultaneous weighing and mixing in cases where cement and additives are mixing directly onto trucks. For high-precision batch type mixing of composite and special cements with mechanical mixers the individual components are fed into weighing bins. Here precision weighing systems (Figure 15) are used for micro components and additives [8]. The feeding of the weighing bins is via flow-control gates which allow a fine tuning of the components into the weighing bins. With this equipment dosing accuracies of better than ± 0.1 % are achieved. The size of the weighing bins depends on the mixer throughputs.

3 Improving the dosing accuracy

The accuracy of a dosing system not only depends on the equipment but on the system design and the control algorithm.

3.1 Prefeeding strategies

The better the prefeeding and the silo extraction can be controlled, the higher is the dosing accuracy. Figure 16 shows three extraction cases in combination with a double rotary weighfeeder (Twin Rotaway) by Hasler. In Case 1 with the direct extraction of the feed material from the silo a simple control loop is possible, where the flow rate is adjusted via the motor speed according to the measured weight and set point. In Case 2 a double regulation loop with a prefeeder is provided via the regulation of a flow control gate behind a weighing hopper, which can be used for the system calibration. In Case 3 in addition to the prefeeder a buffer is provided to have an independent flow control and dosing system with weighing hopper and weighfeeder. Advanced designs can also be used by other dosing equipment for a higher dosing accuracy.

3.2 Reactive/proactive control

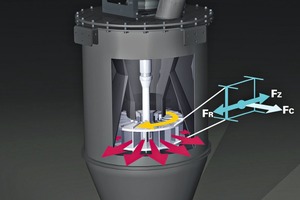

In reactive control, deviations in the feed rate are measured and the prefeeding is adjusted, while the measured feed rate (having deviations) is sent to the process. In proactive control the material mass is measured before it leaves the weighfeeder and the device can be adjusted before the material is discharged into the system. FLSmith Pfister, for example, uses in their rotary weighfeeders a proactive control system called ProsCon (Figure 17). The system checks, if there is a deviation between pre-calculated values and real measured values. It uses the set feed rate and the measured mass to adjust the angular speed of the rotor. Less material in the rotor results in a higher angular speed, more material results in a lower speed. So the material dosing will follow more precisely and without delay the feed rate set point received from the plant control system.

3.3 Modular electronics

Disocont by Schenck Process is an example of a modular electronics system applicable to any weighing and feeding system. It is used wherever bulk solids flows have to be measured or metered with the use of loss-in-weight feeders, weighfeeders, mass flow meters, solids flow meters, belt scales and weighing bins. The electronics is preferably integrated locally into the scale mechanics (Figure 18). So self-contained function units are created. The system is designed to acquire the actual feed rate of the system and adjust it to the setpoint. The internal communication bus of the system permits a flexible arrangement of the I/O units, locally or in cabinets. All modules can be replaced with no need for recalibration and reconfiguration (Plug & Play).

4 Market information and outlook

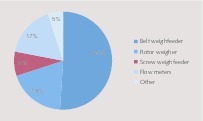

OneStone Consulting conducted a market study on material handling systems in the cement industry [9]. In the market report the market potential for materials handling equipment is segmented by 15 product categories, including the dosing systems in the cement industry. From 2013 to 2015 a total of 1430 systems were ordered worldwide, excluding China. The ratio of dosing/weighfeeding systems to new kiln was 13.5 in 2015, which shows that a significant quantity of the systems ordered is for upgrades and replacements. Figure 19 shows the average share of the different systems in the last three years. Belt weighfeeders dominate the market, followed by rotor weighfeeders and flow meters. Clinker and cement dosing applications dominate the market, followed by pulverized fuels and secondary fuels. More than 25 suppliers are in the market. The three market leaders combine 72 % of the market, which is projected to slightly increase by 2020.

//www.onestone.eu" target="_blank" >www.onestone.eu:www.onestone.eu

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.