Better dosing to the coal mill

1 Development

Holcim Spain started a project at their Carboneras plant (Fig. 1) to improve the pet-coke grinding performance in order to obtain safe and reliable coal mill feeding and to improve the coal mill grinding performance. The start-up of this installation took place in 2010. With rotor weighfeeder Pfister® TRW-K FLSmidth Pfister GmbH from Augsburg, Germany supplied the dosing equipment to the coal mill.

The project included the replacement of the old raw coal feeding equipment to the mill, which consisted of an apron feeder, for the new design of rotor weighfeeder Pfister® TRW-K. This...

1 Development

Holcim Spain started a project at their Carboneras plant (Fig. 1) to improve the pet-coke grinding performance in order to obtain safe and reliable coal mill feeding and to improve the coal mill grinding performance. The start-up of this installation took place in 2010. With rotor weighfeeder Pfister® TRW-K FLSmidth Pfister GmbH from Augsburg, Germany supplied the dosing equipment to the coal mill.

The project included the replacement of the old raw coal feeding equipment to the mill, which consisted of an apron feeder, for the new design of rotor weighfeeder Pfister® TRW-K. This aggregate installed in Carboneras was the first reference installation of raw coal and pet-coke mill feeding in the cement industry. Other installations and replacements of the same type at cement plants, for example in Australia and Poland, followed. The know-how of this specific technology was transferred from the power industry where rotor weighfeeder systems as the Pfister® TRW-K have been successfully in operation since 2003. The operation principle of the equipment is based on the well-known and successful Pfister® rotor weighfeeder technology with more than 2800 units installed worldwide.

2 Application at Holcim Carboneras

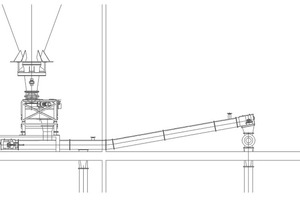

The installation supplied by FLSmidth Pfister GmbH consists of a vibrating hopper (1 m3), a shut-off gate and a rotor weighfeeders Pfister® TRW-K (4.18/5). The installation is a raw coal system to feed the coal mill. It consists of a 70 m³ hopper where the raw coal is stored. The vibrating hopper ensures the constant flow of the material. Installed below there is a dosing system (rotor weighfeeder Pfister® TRW-K) and a drag chain conveyor behind the airlock at the mill inlet. The chain conveyor transports the material either to the mill inlet or to another feed point for truck transport (Fig. 2).

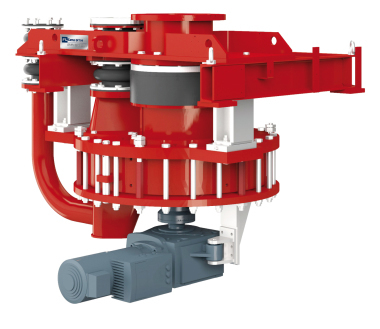

The performance of the TRW-K rotor weighfeeder is laid out to use up to 40 t/h of raw coal with a range of 10-100 % nominal and a precision of +/-1 %. Due to ATEX requirements, the design of the installation is pressure-shock resistant. The vibration hooper, shut off gate and Pfister® weighfeeder are pressure shock resistant up to 3.5 bar.

3 Technical characteristic

The outstanding compact design of the gravimetric TRW-K permits a minimum installation in terms of height. It also results in less maintenance work and a longer life of operation owing to the following features:

No spillage possible, which can affect the operation or which needs to be cleaned. Even sharp parts do not harm the feeder like this is the case with a belt weighfeeder.

Foreign bodies in the coal silo can be removed easily through service openings right next to the rotor weighfeeder inlet.

All measuring parts are accessible from the outside. This makes repair and maintenance work very easy to accomplish.

Wear is minimal, because the coal touching parts of the rotor weighfeeder are made of special wear resistant steel.

Even burning coal could be fed. Minimal wear also results from the low speed of the rotor.

4 Holcim’s experience with operating

The rotor weighfeeder TRW-K is a very reliable equipment, robust and free of spillages. Due to the exact and stable coal and pet-coke dosing for mill feeding the mill grinding performance is increased and mill vibrations decreased (Fig. 3, 4).

After three years of operation no important maintenance operations were necessary.

The spillage free operation and closed system improved the safety for the installation significantly.

The TRW-K is good alternative for raw coal and pet-coke feeding and dosing.

5 Summary

In order to obtain safe and reliable coal mill feeding, the stability and precision of raw coal dosing to the mill are key elements. With its rotor weighfeeder Pfister® TRW-K concept, FLSmidth Pfister offers a future-oriented technology with more than 50 units running successfully in operation since 2003.

The German company does not only supply the single dosing machines. The includes the complete setup and surrounding of the installation like silo engineering, intermediate material transport and safety equipment. That ensures that customers get all engineering from one experience partner and one single source. In the meantime Holcim Cement Australia has also installed a rotor weighfeeder Pfister® TRW-K at their coal mill, feeding 20 t/h.

//www.flsmidthpfister.com" target="_blank" >www.flsmidthpfister.com:www.flsmidthpfister.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.