Coal dust dosing without compromises

In 2008, the FLSmidth Group was awarded a contract worth 60 million € covering machinery and engineering services for the plant that is located 110 km east of Cairo. Sophisticated equipment and in-depth expertise in dosing and feeding fuels to the burners of cement plants came from the German FLSmidth Pfister engineers, working hand in hand with their parent company FLSmidth A/S in Denmark. While the Ain Sokhna plant fired the main and calciner burner with gas when it first opened, the fuel supply was now switched to coal dust for cost reasons. The FLSmidth Pfister installation for feeding these fuels to the main burner and calciner were put in operation a few months ago.

Introduction

An output of more than 6000 t/d of grey Portland Cement makes the Ain Sokhna plant one of the main players in the region. The complete package of FLSmidth machinery included an EV limestone/clay crusher, raw material stores, an ATOX raw mill, CF silo, the complete ILC 3-support kiln including a 5-stage preheater and an SF cross-bar cooler, clinker storage, an OK 42 cement mill and cement silos. The mill is one of the largest cement mills in Egypt. FLSmidth has had an excellent reputation in Egypt for a long time as well as many local reference installations. In this connection the...

Introduction

An output of more than 6000 t/d of grey Portland Cement makes the Ain Sokhna plant one of the main players in the region. The complete package of FLSmidth machinery included an EV limestone/clay crusher, raw material stores, an ATOX raw mill, CF silo, the complete ILC 3-support kiln including a 5-stage preheater and an SF cross-bar cooler, clinker storage, an OK 42 cement mill and cement silos. The mill is one of the largest cement mills in Egypt. FLSmidth has had an excellent reputation in Egypt for a long time as well as many local reference installations. In this connection the FLSmidth Pfister dosing equipment has gained the reputation of being extremely reliable.

A concept without compromises

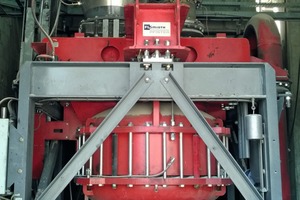

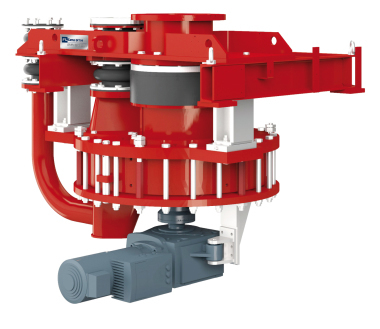

Two rotor weighfeeders Pfister DRW carry out the coal dosing to the pre-calciner and the main burner at the El-Sewedy Ain Sokhna plant. Strengthened with a sufficient capacity margin, the rotor weighfeeder Pfister DRW 4.14 installed at the pre-calciner offers at least an additional 5 t/h. In total it is planned to take into account a dosing capacity of up to 30 t/h. The rotor weighfeeder Pfister DRW 4.12 feeds the main burner at a rate of 16 t/h. Despite the difficulties normally accompanying the coal dust dosing process, the perfect dosing concept of FLSmidth Pfister is running impeccably at the new El-Sewedy plant. It is a “concept without compromises”, based on a combination of a smart progressive design of the dosing equipment and high-quality components and materials.

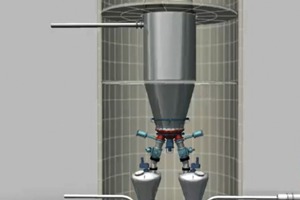

This smart design includes coal dust silos with a cone made of premium stainless steel. Stainless steel silos do not corrode, their inside surface stays smooth for easy material flow. Coal dust will not stick to the walls, which is a must for unobstructed feeding. Proper aeration of the silo cone with an optional choice of ambient air or inert CO2 gas is an additional important means to ensure the necessary material flow.

As a distinct characteristic of high accuracy and low maintenance, the pneumatic transport of coal dust is integrated inside the rotor weighfeeder Pfister DRW. With dosing chambers being blown through continuously, the rotor as the heart of the feeding system stays clean and will not be blocked by residue. Clogging and the possibility of a “heart attack” inside that highly important processing component is therefore practically unlikely. The result: no costly shutdowns due to malfunctioning equipment.

Faster is not always better

While other rotor weighfeeders swirl at a rate of several hundreds and more rounds per minute, wearing out bearings, hosing and consuming loads of energy, the rotor of Pfister rotor weighfeeders turns at less than 10 times per minute. Combined with its well-designed and integrated pneumatic transport, the rotor is able to convey the required amount of pulverized material into the burning area. At the same time it is slow enough to keep wear and energy consumption at a minimum.

El-Sewedy chose the so-called block systems for pulverized fuels with integrated pre-hoppers.

A unique and cost wise always discussed design feature is the highly recommended pre-hopper from FLSmidth Pfister. It offers to operators four indispensable advantageous characteristics:

More independence of possible flow problems inside the coal dust silo. The pre-hopper ensures that there is always material above the inlet of the rotor weighfeeder which acts like a cache between the rotor weighfeeder and the main silo.

To improve the material flow, the pre-hopper can be equipped with a stirrer to ensure that material will not stick to the wall of the pre-hopper. This can occur when using coal with higher moisture or when using fine petcoke.

Because the pre-hopper is located above the rotary feeder, the system works with overpressure in the pre-hopper. That allows operating with a higher pressure difference. This advantage can be used for longer conveying distances or higher loads (coal-air-ratio).

The block system can also be used for online calibration. With online calibration, the accuracy of the rotor weighfeeder can be checked at any time during normal operation and any deviation can be corrected automatically.

Smart dosing principle

FLSmidth Pfister‘s patented prospective control ProsCon guarantees constant control of the complete material feeding and dosing line and is an important part of the orchestration: Prospective control ProsCon uses a set feed rate and measured bulk mass to calculate the angular speed of the rotor. Less material in the rotor results in a higher angular speed, more material results in a lower speed. ProsCon-regulated rotor weighfeeders accurately compensate variations in rotor loading and material density. Extremely accurate short- and long-term feed rates, which can be altered quickly without loss of precision, are the result of smart design and engineering know-how developed over many years of intensive testing and research. While other feeders only react on requirements, ProsCon pro-actively regulates feeding in a real-time answer to measured deviations. Perfectly attuned pre-feeding devices complete the smart package.

Increase of dosing capacity to 30 t/h

at no additional costs

The cooperation with the dosing specialists from FLSmidth Pfister GmbH was a winning combination in the project. Gamal El-Laithy of El-Sewedy Industries was particulary pleased by the flexibility of the setup: “We not only had a successful installation of Pfister dosing equipment, we are also able to increase the capacity of the pre-calciner from the originally planned 25 to 30 t/h without any additional costs”.

In the El-Sewedy project, the main source of energy is currently coal dust. An originally planned backup fuel supply with natural gas often proved to be superfluous, since coal dosing with Pfister rotor weighfeeders works like the proverbial clockwork.

//www.flsmidthpfister.com" target="_blank" >www.flsmidthpfister.com:www.flsmidthpfister.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.