Drive train condition monitoring

Condition Monitoring has become an essential element for the digitalization of industry. The reasons are obvious: the smooth and uninterrupted availability of production facilities is top priority for companies operating plants, as this is the only way to guarantee maximum productivity from production systems. In an ideal situation, a condition monitoring solution should be a package from a single source, comprising an integrated system and services.

1 Introduction

An efficient condition monitoring solution such as Siemens’ Drive Train Condition Monitoring (DTCM) is integrated into the automation system and monitors the entire drive train. The main focus is on motors and mechanical transmission systems, to ensure that potential damage is identified and rectified – or averted – at an early stage. This monitoring system also carefully analyzes how individual components operate together. The monitoring data is combined within a single system and is evaluated in detail by experts in the form of condition reports. This means that plant...

1 Introduction

An efficient condition monitoring solution such as Siemens’ Drive Train Condition Monitoring (DTCM) is integrated into the automation system and monitors the entire drive train. The main focus is on motors and mechanical transmission systems, to ensure that potential damage is identified and rectified – or averted – at an early stage. This monitoring system also carefully analyzes how individual components operate together. The monitoring data is combined within a single system and is evaluated in detail by experts in the form of condition reports. This means that plant operators are kept constantly up to date and can take any necessary action without delay. This avoids costly plant downtimes, reduces maintenance costs and enables service intervals to be optimized.

2 Still perfect after 22 years

of continuous operation

The case of a cement factory in southern Germany demonstrates how well a DTCM system can pay off. The factory has used a Flender KMP590 gear unit for 22 years, and years of reliable operation can still be expected, not least thanks to the many years during which its condition was continuously monitored.

The condition monitoring system was installed on the gear unit of the vertical mill drive in 1998 – and just in time, since a damaged motor bearing was diagnosed when the very first measurements were taken. This was quickly rectified during a brief, scheduled downtime.

A cost-efficient retrofit was performed in 2009: the main component of the CMS was replaced, however the sensors and cables were kept. A further milestone was reached in 2013 with the conversion from analog to broadband remote connection technology: the system can now be conveniently parameterized using the faster data transfer technology; when necessary, even large data volumes can be transmitted at lightning speed for diagnostics. The online signals can be viewed in the remote diagnostics center in what is essentially real time.

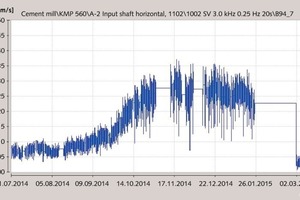

The DTCM system definitively proved its worth in early 2014: as part of the regular six-monthly reporting process, there were the first clear signs of damage to the inner ring of the roller bearing at the motor end of the gear unit input shaft. The experts involved recommended repairs over the long term. The customer hoped to continue production through to the scheduled winter downtime in February 2015. This meant that the best possible use of the remaining roller bearing service life had to be made, with condition-based maintenance helping to mitigate the risk. The damage that had already begun was then closely monitored to ensure a swift response if the condition of the bearing worsened – or if there were any signs of consequential damage (Fig. 1).

And the strategy worked: the maintenance work ran smoothly on the scheduled date as the long lead time had been fully utilized to organize spare parts and experts in advance. The replaced bearing revealed exactly the damage that was expected: no substantial consequential damage had occurred, and the repairs could be performed on site. This allowed the actual downtime to be kept to a minimum, and the plant was able to quickly resume operation.

3 DTCM on Multiple Drive

The example provided by an Indian cement manufacturer also shows how a DTCM system can make a noticeable difference to service and lifecycle costs. The special aspect to this case was that development, construction, setup, service and condition monitoring for the drive train were procured from a single source in the form of a Siemens Integrated Drive System (IDS).

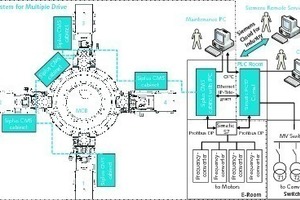

With the novel drive design for vertical mills, known as “Multiple Drive,” four separate drive units mesh with a ring gear on the drive train, which means that the appropriate load balancing is crucial. If the drives work against each other or oscillate uncontrollably because the controller parameters were incorrectly set, for example, in a worst-case scenario, this would damage the teeth or bearing. This is why the DTCM system installed in the factory focuses on monitoring mechanical drive torque values. To achieve this, for each drive unit the torques of the various drive shafts in the auxiliary gear unit are monitored using strain gauges. Torque values are monitored against limit values and dynamic rates of change; deviations from specified limits trigger an alarm or the events are recorded with a high resolution. The frequency converters also transmit the calculated motor torque signals to the DTCM system.

To monitor the sleeve bearings on the reduction gear unit input shafts and the roller bearings on the intermediate and output shafts, oil, temperature and vibration are all monitored for each drive unit. The roller bearings on the driven end and non-driven end of the modern drive motors are also monitored for vibration. The DTCM system also monitors hydraulic pressure in the hydrostatic axial friction bearings and the temperature of the friction bearings on the ring gear and grinding plate flange on the mill center body. Position measuring systems are used to monitor radial and axial runout errors and also the connection holding the split ring gear together.

To minimize wiring costs during commissioning, in each case, all of the sensors are installed in the factory and wired through to the intermediate terminal box attached to the steel frame (Fig. 2). The intermediate terminal boxes also contain the interface nodes that digitalize all of the analog signals already after short signal cable lengths. The prewired control boxes mounted on the mechanical drive units with the interface nodes are networked using fiber-optic cables during commissioning onsite. Despite high sampling frequencies of vibration signals and a large number of channels, this allows a large bandwidth to be achieved to transfer the synchronously sampled signals to the PC used for analysis, even over considerable distances

In addition, data from the frequency converters – e.g. active power levels and speed signals from the incremental encoders – is also fed into the DTCM system for each software interface. The higher-level process control system records essential process data such as material volume flows, temperatures and pressure. If gear unit vibration occurs, correlation with process statuses makes it easy to distinguish damage-related from process-related vibration events.

Overall, a total of 115 signals are recorded from the electromechanical drive train using the Siplus CMS monitoring system and saved on the local RAID hard drive system on the PC used for analysis. The computer is connected to the Siemens Cloud for Industry platform; diagnostic experts in Germany are responsible for the parameterization and monitoring (Fig. 3).

Continuous monitoring by the DTCM solution is based on an operational class plan. What this means is that different, frequently occurring load statuses are defined, for which threshold values are monitored together with the alarm values set in accordance with the process conditions in question. Fourier spectra are used to monitor periodic parameters that could indicate damage. The DTCM system thus continuously monitors the high-speed and variable-load system with a clear focus on identifying possible bearing and tooth damage, and as higher-level early warning system, prevents costly machine failures and plant downtimes.

4 The key to efficient plant operation

Both of these case studies show that Siemens DTCM systems provide a permanent, transparent picture of plant conditions, reducing risks of outages and also the costs associated with downtimes and maintenance. But there are additional advantages: comprehensive analysis results enable the best possible maintenance strategies to be developed, along with a much more cost-effective logistical setup for companies operating plants.

In both case studies, preventive maintenance strategies were able to be transitioned into condition-based ones that brought costs down. Unplanned and costly plant downtimes are things of the past, in the plants in southern Germany and India. By analyzing the data recorded by the DTCM system, damage can be quickly identified and located, even in the early phases. In the best case scenario, damage – and potential consequential damage – can be avoided in the first place. If damage is subsequently identified, then it can be quickly resolved. The damage analysis precisely determines which spare parts and tools are needed. This significantly reduces outage costs as well as repair costs.

If, as in the case of the plant in India, Siemens supplies the entire drive train as part of Integrated Drive Systems, the company also provides training for technicians, who will then be able to service both the electrical and the mechanical drive train components; this is another way in which service costs can be substantially reduced. A further contributing factor is that a long-term service contract means that there are no coordination and interface problems, as there is just one contact person who is responsible for all of the interests of the company operating the plant.

The example of the gear unit in the plant in southern Germany also clearly underscores the impact that a full DTCM system has on a maintenance strategy: analysis results enable risk-free, purely condition-based maintenance of the individual components. This means that components that are still intact are not replaced and it is avoided that highly-stressed components unexpectedly fail before the end of their useful service life. In other words, intelligent maintenance safeguards investments over the long term.

The data recorded in the DTCM system also provides a statistically sound basis for estimating which spare parts will be needed, and how often. Pools of spare parts for these components can then be created at logistically practical locations. This ensures that they are available quickly in the event of a breakdown and it also keeps warehousing costs to a minimum; in other words, stock inventory can be optimized, which is another area where major savings can be achieved.

DTCM systems can be used to cost-efficiently retrofit older condition monitoring systems. If an existing plant or system is modernized, as in the case of the cement factory in southern Germany, the advanced DTCM solution significantly extends the service life of the production machinery: continuous monitoring minimizes the risk that the older components will fail, and condition-oriented maintenance can optimize the service life of individual components.

5 Conclusion

In a nutshell: an efficient DTCM solution takes over the whole job of monitoring the drive train from a single source and significantly increases plant availability and productivity, while reducing maintenance and repair costs. As a result, companies operating plants can fully concentrate on their core business.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.