Condition Monitoring increases availability of vertical mills

Condition Monitoring increases availability of vertical millsLimestone, clinker or coal: the cores of vertical mills that crush such materials are the drives. An operator increases availability by relying on an integrated condition-monitoring system right from the commissioning. Thus, early failure detection and, in combination with remote service, even trouble shooting is possible – and maintenance costs can be reduced.

Condition Monitoring Systems:

rather integrating than retrofitting

The use of Condition Monitoring Systems (CMS) is state of the art in modern industrial plants. However, they are still retrofitted in already existing plant components, since many companies spare investment costs when installing new plants or they do not consider necessary the use of CMS during the warranty period. Apart from the general advantages, even disadvantages occur, such as increased investment costs, interface problems or poor accessibility of installation sites. Thus, retrofitting of a main drive, for instance, is...

Condition Monitoring Systems:

rather integrating than retrofitting

The use of Condition Monitoring Systems (CMS) is state of the art in modern industrial plants. However, they are still retrofitted in already existing plant components, since many companies spare investment costs when installing new plants or they do not consider necessary the use of CMS during the warranty period. Apart from the general advantages, even disadvantages occur, such as increased investment costs, interface problems or poor accessibility of installation sites. Thus, retrofitting of a main drive, for instance, is often only a compromise: for example, the sensor positioning of the accelerometers outside the gearbox is often unfavorable, as structure born noise transmission from the vibration source to the sensor at the machine housing is not optimal. Moreover, the subsequent laying of sensor cables in the field is complex. Also, the integration of the Conditioning Monitoring Systems into the existing automation environment involves considerable effort and is sometimes only insufficiently achieved.

CMS of the new generation however allows for the deep integration into the automation technology. In contrast to previous systems, where high-resolution measurements on several channels could only occur serially via signal multiplexers, modern systems work synchronously at high channel numbers and are moreover modular expandable. Such factory-installed monitoring systems can show their advantages already during plant commissioning. These advantages include a simplified test bench run after the final installation, since acceptance measurings are already made by means of the CMS. Moreover, commissioning time is reduced, as automation engineers, converter experts, motor experts, transmission experts and plant manufacturers have access to a consistent database. At the same time, operating errors and overload of the drive train can be avoided during commissioning, as threshold monitoring of vibrations and loads is active right from the beginning. Even performance indicators and reference states are available from the first day, which is useful in particular with trend analyses. Another advantage is the simplified troubleshooting throughout the entire process and drive train, since all signals are available on a software platform. And last but not least, the factory-installed system provides operators with complete knowledge of all machine states and special events during the whole lifecycle. These advantages of integrated CMS will be explained below taking a vertical mill, automated with Siemens drive technology, as an example (Fig. 1).

Smooth-running vertical

mill gear units with integrated motor

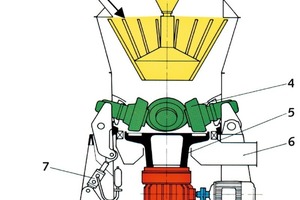

Vertical mills are used in particular for the crushing of limestone, clinker, slag, lime and gypsum in the primary industry as well as of coal in power plant technology. They grind the raw material with a thickness of up to 60 mm (Fig. 3) to a very fine grain size in the µm range and play a key role in the production process. With the layout of vertical mills according to Fig. 1, a wear-resistantly armored grinding table (5) is rotated by a Siemens vertical mill drive (1, 2, 3). The two to six wear-resistant grinding rolls (4) are stationary, but vertically movably connected to the mill frame and due to their own weight, supported by hydraulically applied forces (7), they press onto the grinding table (5), where the mill charge, fed by the material feeding, accumulates. Heated air for drying is blown in via the hot-gas feed (6). The ground product is continuously exhausted by the air separator, whose drive is also available from Siemens.

The gearbox (Fig. 2) is virtually the pivot of a vertical mill. Here, all drives must provide highest performance in little space at maximum availability. The new Siemens drive concept Flender EMPP offers the optimum synthesis of mechanical and electrical drive technology: the variable speed drive consists of a newly developed motor which is directly connected to two planetary stages. It goes without open components and is particularly reliable and smooth. The motor is actuated by a frequency converter and is particularly suitable for vertical mills in the performance range of several megawatts. The brushless permanent magnet synchronous motor with slide bearings directly integrated in the gearbox housing is a special feature. This drive is particularly robust and has a high protection class, inter alia due to the elimination of the wear-prone bevel gear stage and clutch, since outward dynamic oil sealings are not required.

Merging status information

of automation and additional sensors

When first dealing with the issue of Condition Monitoring at rotating drives, one often wonders why, apart from the automation system, an additional measuring and analysis system is necessary at all. This is basically due to the high signal sampling rates required. Wear-related damages to the rolling bearings for example are mostly reflected in an increase in structural resonance amplitudes in the range of 3 to 8 kHz. In order to avoid aliasing effects, sampling rates of 24 kHz (0.042 ms) or more (resp. shorter keying times) are required for vibration measuring. The high sampling rate is accompanied by the need for huge working memory and high computing power for the compression of raw measuring data. These requirements were usually not fulfilled by previous automation systems. Thus, for vibration analysis and highly dynamic torque monitoring particular measuring technology and analysis methods are indispensible. Further status-relevant sensor data, anyway available in the automation system, can also be included in Condition Monitoring system.

Optimum use of CMS through

combination with remote access

IT safety concerns and lacking confidence are often stated as reasons for not allowing remote access to industrial systems. Siemens offers a solution which enables the reduction of risks to a minimum. The Siemens Remote Services thereby rely on the common Remote Service Platform (cRSP), which is already established in other branches worldwide, such as medical or energy engineering. The security of the remote connection is ensured by certified infrastructures according to ISO 23001 as well as strict safety standards.

The separation of the networks by a so-called perimeter network guarantees freedom from feedback. Secured connections via encrypted tunnels based on IPsec or SSL ensure that data traffic cannot be intercepted. In this case, the high safety standard also impressed the customer.

Positive experiences as from the commissioning

Condition Monitoring Measurement was first used in the test run of the cement mill equipped with the Flender EMPP drive. The measuring technology immediately displayed its excellence, since a small failure in the test bench setup, which could have resulted in severe damages, was detected at once: due to excess oil, the splashing losses which occurred in the motor air gap were so high that inadmissibly high temperatures arose at the permanent magnets. Undiscovered this could already have led to preliminary damaging of the motor rotor. The further test run proceeded without any problems; all signals were recorded and documented by means of the CMS.

Due to the largely completed, tested, and partly pluggable cabling, the installation of the customer plant could occur quickly and smoothly. Then, the exciting moment came when the drive below the mill was started for the first time. Here, another advantage of the CMS became obvious. The Microbox PC used for data logging has already been installed in the operator room in another building about 100 m away, and connected via optical fiber cable (OFC). During the first commissioning however, the commissioning engineer wanted to be as close as possible to drive and converter to see the high-resolution measuring data online (rotational speed, torque, converter signals). Since the measuring system is networked via Firewire, instead of the Microbox PC a notebook, could be used for data logging and visualization, which was installed in close proximity to the drive next to the notebook to operate the frequency converter (see Fig. 4). In order to evaluate the influences of the control parameters on the drive dynamics, online frequency analyses of the torque signal were calculated and displayed in real time by means of the Condition Monitoring System.

Another advantage of the modular concept arose, when the commissioning engineer asked for the temporary documentation of further converter signals and external signals, which had not been provided during project design. This request could be granted within a few minutes by connecting a “Siplus CMS Analog Input Node” to the CMS bus system via Firewire. The additional data were immediately available and with chronological synchronism to the other data. On completion of the commissioning work, the Node was simply dismantled again.

With the possibility provided by the Siplus CMS to carry out real time calculations of all measuring signals, such as Fourier spectra (on the basis of an integrated FFT function), the quick diagnosis of all measuring signals was possible already at an early stage. In this case, during the test run it was detected that the quality of the speed sensor signals had to be improved through renewed alignment. In the course of commissioning, the optimization of the controller parameters could be simplified by the online set-off of different measured values with synthetic factors. The influence of different parameters and controller structures was immediately comprehensible and documentable. The analysis of process failures was greatly simplified through the synchronicity of the signals, as process signals and dynamic drive signals could be correlated. On completion of the first commissioning work, the Condition Monitoring System was switched to the monitoring and recording mode. The torque signal of the Condition Monitoring System is used as overload protection and causes process stabilization via converter. Thus the CMS protects the drive from the first minute.

In the further course, the converter parameters were optimized. Here, the safe remote access via common Remote Service Platform (cRSP) was advantageous, since the converter expert could carry out parameter changes through remote access via Microbox PC in consultation with the customer, without having to travel to the plant. The optimization of the converter parameters and the related improvement of torque and process dynamics were documented by means of CMS, the reference states were determined. Since then, the drive has been running without problems and with high availability.

Conclusion

A modern CMS, deeply integrated into automation, provides numerous advantages – in particular, when coupled with secure Remote Service. Experience shows that the availability of drives can be demonstrably increased while maintenance costs can be reduced. For the future it is to be expected that based on comprehensive field experiences, the quality of automatic diagnoses will be further refined. The standard integration of highly dynamic torque measuring systems in the drive trains will mean that damages will not occur at all, because overload is avoided and more precise forecasts regarding the residual life are possible on a profound data base. Such forecasts are an essential contribution to the increase in availability and productivity of complex automated plants.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.