CNA in the quarry – problems and solutions

Operational stability remains a key objective in any plant performance. On the way to

achieving this goal, there are many obstacles to be overcome – from raw materials to production processes and technical equipment. At the starting point, quality control is essential as disturbances will “echo” throughout the process making smooth and efficient operations impossible.

1 Introduction

The cement industry continues to develop the cement making process in order to produce cement in a “better” way. “Better” covers a wide range of parameters from production cost, cement quality, cement properties and of course environmental impact. While there have been many new and exciting developments in these areas, many of the challenges of controlling the cement process remain unchanged from the early days of the industry.

Operational stability remains a key objective and standing in the way of this goal are many causes of variation and malfunctions. The raw materials,...

1 Introduction

The cement industry continues to develop the cement making process in order to produce cement in a “better” way. “Better” covers a wide range of parameters from production cost, cement quality, cement properties and of course environmental impact. While there have been many new and exciting developments in these areas, many of the challenges of controlling the cement process remain unchanged from the early days of the industry.

Operational stability remains a key objective and standing in the way of this goal are many causes of variation and malfunctions. The raw materials, usually drawn from sources with innate variability, are a key challenge. Producing a chemically correct and stable raw material is a requirement in order to support a smooth running pyroprocessing operation. Without a stable raw material, the perturbations will “echo” throughout the process making smooth and efficient operations impossible.

2 Neutron-based bulk material analysis

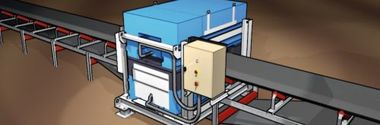

Neutron-based instruments have been effectively used for this purpose for over two decades. These analyzers have the advantage of interrogating nearly all of the material that passes on the belt and they quickly provide an elemental analysis of the material they “see”. Since the analyzer is based on nuclear interactions, the results are independent of mineral structure. Unlike x-ray analyses (XRF), near infrared (NIR) or laser induced breakdown spectroscopy (LIBS), the nuclear instruments can provide a relatively accurate analysis of the entire process volume.

The first nuclear instruments were isotope based. The material passed under (or over) a neutron emitting isotope (often Californium-252) to activate the raw material nuclei and the resulting gamma radiation was measured. For more than a decade, the lifetime of electrical neutron tubes has increased to where tube-based analyzers are efficient and practical. The PANalytical CNA (controlled neutron analyzer) that features Sodern neutron technology is the most common of these analyzers.

The tube-based instruments provide a number of advantages over isotope-based systems:

Safety – Since the neutron flux is generated by an electrically powered tube, a simple electrical interlock can stop the neutron flow to allow safe access to the analyzer area and its internals. While shielding is available to secure the area even while the analyzer is operating, often a simple fence and proximity switches can provide unmatched safety for plant personnel.

Controllability – The neutron flux from an electrical tube can be controlled by adjusting the voltage and current to the tube. Internal feedback loops measure and regulate the neutron flux in order to provide stable operation over the life of the tube. Isotopes generate neutrons by internal decay and their half-life is a measure of the rate of that decay. Californium-252 has a half-life of just over 2.5 years, which means after this time the neutron flux is literally half of a new unit. Source replenishments and internal calibration adjustments are required to compensate for this continuous decay. In spite of this, as the replenishment approaches, the reduced neutron flux negatively impacts the operation of the analyzer.

Reliability – Neutron tubes are very reliable. Once energized, the tube will likely function optimally for the rest of its lifetime – often in excess of 12 000 operating hours. Despite this, spare tubes are typically available to provide an extra layer of assurance. Isotopes are also reliable but need to be replenished every 2 years from a somewhat volatile and often uncertain market.

In order to properly discuss and apply a solution, it is important to clearly define and understand the problem. Quarry operations clearly fall under this rule. Cement quarry operations can span wide ranges of configuration – simple to complex and operation - sophisticated to very basic. A sampling from these ranges is outlined below:

3 Quarry problems

3.1 Stable quarry

A stable quarry often requires minimal control effort as there are few surprises as the rock is extracted. Still, particularly in high production plants, the cost of the occasional upset from the quarry more than justifies a stockpile and an analyzer to monitor its composition.

3.2 Complex quarry

Complex quarries can have significant chemical variation from bench to bench as well as intrusions of undesirable material.Close monitoring and feedback is required to create a stable stockpile. Sorting can be required to divert rock high in undesirable components to aggregate operations or scrap piles.

3.3 Aging quarry

Many quarries are approaching the end of their planned life, however finding and permitting replacements can be an expensive and time-consuming process. In many cases, close monitoring and control of the quarry output can extend the life of the quarry (and perhaps the plant), well beyond the initial expectations.

3.4 Off-site sources

A number of plants, particularly those that can be supplied by water, obtain their raw materials from off-site quarry operations or independent suppliers. These materials can be supplied directly from the quarry or pre-homogenized at the quarry. In either case, close monitoring of the chemistry of the arriving raw materials is required to provide information for further blending or alarm when off-spec material arrives.

4 Solutions

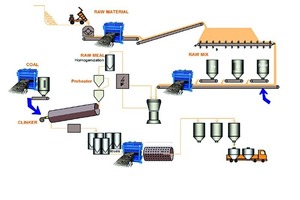

In order to match the solution to the problem, a CNA analyzer can be installed in a number of configurations:

Measure only – In cases where limited corrective action is required, the CNA can be installed after the primary crusher to monitor the composition of material fed to the stockpile or blending pile and alarm upsets of off-spec material.

Measure and Control – In cases where frequent corrective action is required, the CNA can be paired with pile control software to provide feedback to the quarry operation and calculate the type of material (benches) required to bring the pile to specification. While the mix calculations for piles are fairly straightforward, providing useful feedback to the quarry operators can be challenging. In plants with a mini-control room in the quarry, the control information can be displayed on a supervisor’s desk and he can radio instructions to implement the corrections. In many plants however, the quarry staffing is lean and direct communication with the truck drivers, either with mobile terminals or a series of traffic lights is required. In any case, smooth communication and feedback is an important link in the chain of raw mix control.

Mix on the pile – In some plants, the goal is to create a pile very close to raw mix composition. This minimizes the material handling and corrections required near the raw mill. In addition to quarry components, correcting additives are stockpiled at the quarry and metered onto the pile, typically via a front end loader. The corrective materials must be added with consideration of the pile geometry in order to have them distributed uniformly throughout the reclaimed pile.

5 Benefits

One of the challenges of accurately producing quality raw mix is knowing the chemical composition of the components. If the composition is known for all components, the mixing becomes a trivial operation. Usually, this is not the case as often historical compositions or results of grab samples are used for blending. With a CNA and homogenizing stockpile, mix control software can provide an accurate estimate of the composition of the material from the quarry which is the bulk of the raw mix. This leaves only the composition of the additives in doubt and enables the production of a tightly controlled raw mix.

6 Conclusions

CNA and other nuclear-based instruments continue to be effective in measuring and controlling the raw mix composition. They can be employed to measure stockpile feed, raw mill feed, or both. The stockpile applications have been highlighted in this article and play a major role in achieving raw material stability.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.