Integrated quality assurance from the quarry to the raw meal silo

If lime, marl and clay from different sources in variable quality and alternative raw materials are fed to a mixing process, a specific strategy for the mix-bed structure and in controlling the material composition before the mill is required. ABB there has such a system, which is presented in the following.

1 Introduction

1 Introduction

This article describes the application of the Expert Optimizer (EO), an expert system from ABB, utilizing the Raw-Material-Proportioning (RMP) strategy. As a mixture control system, it regulates the blending bed stacking to ensure the achievement of a set material composition upstream of the mill. It operates as an integrated system together with the monitoring analysis systems and the necessary infrastructure. Particular consideration is given to the differences between neutron activation systems and near-infrared systems.

2 Objectives

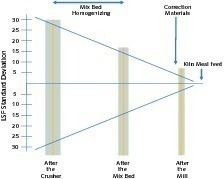

In order to better understand the task involved, one should first consider the course of the decrease in lime standard that is necessary for the production of a raw meal that has an LSF standard deviation of one (1). Figure 2 shows the typical course that is to be found in many cement factories where there is no mixture control system for the blending bed and a laboratory-assisted manual mixture control is installed upstream of the mill. It is clear that optimization in the blending bed sector would result in a significant reduction of the LSF standard deviation after the blending bed.

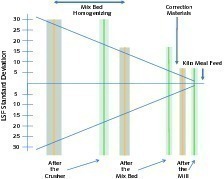

Figure 3 shows (in green and light grey) an optimized mixture control, which can be achieved by using an expert system together with online analysis systems.

Due to the reduction in the LSF standard deviation downstream of the crusher, the material being discharged from the blending bed shows a constant ratio of decrease in the LSF standard deviation – due to the homogenizing effect of the blending bed and the optimization effect achieved by applying an expert system. This in turn provides an optimized starting point for the mixture control upstream of the mill and allows a reduction in the usage of expensive corrective materials, while enabling greater use of alternative raw materials.

As the LSF standard deviation downstream of the mill is already almost at the same level as that of the preheater feed meal, the retention time of the raw meal in the blending silos is considerably reduced, which leads to an additional reduction in power consumption.

3 EO/RMP concept for the blending bed

In the case of material delivery by truck, it is necessary to have a good overview of the material composition in the quarries, so as to feed specific grades of material to the crusher. For this purpose, the areas to be quarried are previously analyzed by bore hole analysis, which provides a rough plan of the material distribution in the deposits. In order to later extract a specific material quality, segments of the quarry with different material compositions are defined.

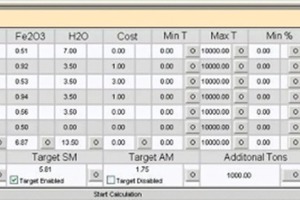

The material segments with their respective bore hole analysis data are entered in the EO/RMP. At the same time, the setpoint values for lime standard and the other control moduli are also specified in the EO/RMP.

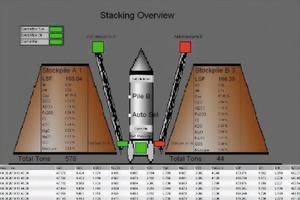

The available trucks and their tonnage can optionally be allocated to the segments of the quarry, in order to incorporate them into the process sequence by means of targeted routing of the trucks. Figure 4 shows the input mask for the segments of the quarry/pit. In this mask, it is possible to activate or deactivate individual segments and thus narrow down the range of materials to be supplied.

Figure 5 shows the input mask for allocation of the trucks to the segments of the quarry and their tonnage.

The material now delivered by the trucks passes through the crusher and is then examined by an online analyzer. The analysis data – together with the tonnage data from the conveyor scale – are adopted by the EO/RMP and the average values, related to the entire blending bed, are calculated for the desired control parameters. As the bore hole analysis only provide a rough overview of the material distribution, there are always deviations between the expected material composition and the actually delivered one, and the same applies to the delivered material quantities, due to fluctuations in the loading of the trucks. These deviations have to be taken into account in the calculations for the materials still to be supplied.

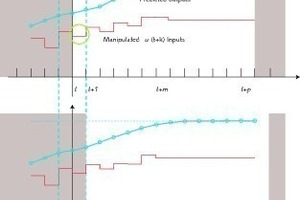

This is where the Model Predictive Control (MPC) and Mixed Logic Dynamics (MLD) modules of the EO/RMP come into use (Fig. 6).

MPC can be imagined like a chess match. One of the players is the process, the other is the EO/RMP. After every delivery of material by the trucks, the EO/RMP compares whether the prediction for the delivery (i.e. the reaction of the opponent) matches the actual values. If deviations are ascertained, the complete sequence of deliveries is recalculated on the basis of the determined deviations (comparable with a new sequence of chess moves). The calculations also take account of cost functions for each segment of the quarry, which are defined in advance, e.g. limestone weighted with a high cost factor, marl and clay with low cost factors.

Moreover, limiting logical conditions are also available. This is the function of the MLD, which enables the linking of pure analog and digital data with logical conditions and restrictions, e.g. the number of available trucks, their tonnage and the time required for fetching the material from the quarries. All the deviations, conditions, restrictions and cost functions are taken into account in the calculation of the materials to be delivered, and result in a mixture calculation that incorporates optimized logistics and cost involvement. The operator of the crusher control panel is then responsible for passing on the information to the truck drivers.

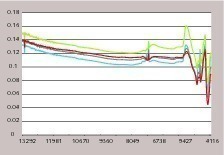

Naturally, the EO/RMP calculations depend on the availability speed and reliability of the analysis data. These factors differ considerably, depending on the installed online analysis system technology. All the systems available on the market provide analysis data at one-minute intervals (Fig. 7). However, systems operating on the basis of neutron activation (PGNAA) only provide a rolling average over a period of 10 minutes, as the standard deviation of analysis data on a one-minute cycle is too large.

At the moment there is only one system available on the market that is based on near infrared (NIR) technology. This technology provides a real analysis value over a period of one minute. From this results a decisive advantage: The EO/RMP can only utilize the rolling average of PGNAA systems to a limited extent and can only incorporate the correction between expected and actually delivered material composition into the calculations over a lengthy period of time, because the rolling average does not really represent a “mixing” of the deliveries. In the crusher itself only a small degree of material mixture actually takes place, because the raw materials delivered to the feed hopper form layers that pass through the crusher successively. For this reason, the near infrared (NIR) technology can be employed to directly detect changes from raw material to raw material and enable a correction calculation of the material fluctuations with each material delivery.

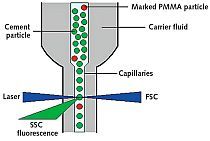

The second advantage of this system lies in the analysis technology itself. First, one has to understand how NIR functions. So-called near infrared technology utilizes the entire width of the near infrared spectrum created by a light source. The generated NIR light falls on the material to be analyzed and excites the infrared-sensitive molecules in the material into oscillations. The resultant typical reflection and absorption spectra contain the entire molecular and mineralogical information of the analyzed material. Figure 8 shows a typical absorption spectrum of limestone.

This is the decisive advantage of NIR technology. NIR can distinguish between carbonate and oxide while PGNAA cannot. In the case of PGNAA a constant loss on ignition is assumed, so the measured values of calcium, potassium and possibly magnesium are correspondingly converted from carbonate to oxide. However, if alternative raw materials that do not contain carbonates are employed, and these are put through the crusher, the LOI calculation is no longer correct and the analysis results show more or less serious errors, depending on the amount and variety of alternative raw materials employed. The system, which is based on NIR, is specially customized to the customer-specific raw material situations and therefore produces correct analysis values.

When the material is delivered by truck, the formation of layers in the blending bed is broken up rather than completely eliminated but there is nevertheless a significant improvement in the standard deviation of the control parameters when the material is extracted from the blending bed, and the setpoint values are better achieved.

A further improvement can be achieved if different apron conveyors are used upstream of the crusher for the limestone, marl and clay. This would mean that the Expert Optimizer is working with defined streams of material, making quick and direct controlling possible and thus allowing the blending bed to be operated to precisely meet the setpoint values with minimum standard deviation.

Different installations in the blending bed with EO, RMP and a corresponding online analysis system have proven that a standard deviation of less than 5 (< 5) in the lime standard of the material extracted from the blending bed can be achieved without any problem.

4 EO/RMP concept for raw meal production

The classical variant is sampling downstream of the mill in a homogenizing tank, with one sample being dispatched every hour to the laboratory. On the basis of the analysis data, the setpoint values for the dosing devices are then calculated. However, as the setpoint values are available only once per hour, the possible degree of control is limited, or it may even be very difficult to make corrections. Moreover, this method is prone to a sampling and sample preparation error that can only be roughly estimated.

Therefore it is better in this case, too, for an online analyzer to be employed – either upstream or downstream of the mill. The selection of its location strongly depends on the chosen technology of the online analysis system, and on whether all the materials to be used can also be identified by the system. If only the classical corrective materials are to be used, upstream of the mill is the appropriate location for PGNAA systems. However, if alternative raw materials are used, and are fed directly into the mill, it is essential to locate the system downstream of the mill. The problem is that PGNAA systems are not designed for this location.

Another disadvantage of the location upstream of the mill is that the system cannot take returned kiln dust into account. Although, a constant chemical content of the kiln dust is normally assumed, this is not the case in actual operation. No matter whether PGNAA systems are installed upstream or downstream of the mill, their online analysis values have to be constantly compared with the laboratory analysis values and the results also have to be used for compensating the drift of the analyzers.

If the alternative raw materials fed in upstream of the mill contain no carbon, it is essential to use LOI-free fused tablets for the laboratory analysis, in order to obtain correct correction values for the PGNAA systems.

For the above control tasks, the Airslide Analyzer combines the classical check sampling downstream of the mill and subsequently laboratory analysis with the advantages of state-of-the-art online analysis systems.

Figure 9 illustrates the effect of combined application of EO/RMP and Airslide Analyzer, comparing this with a combination of EO/RMP and a laboratory-supported analysis system.

For the laboratory analysis system, a sample was taken every 40 minutes from a homogenization tank and transported by pneumatic tube system to the laboratory. There, the sample was processed and examined by X-ray fluorescence analyzer. This means that only hourly values were available to the EO/RMP for the control function.

As soon as the analysis setup was switched over to analysis data from the Airslide Analyzer, – which happened approx. one third of the way along the overall indication, starting from the left – a significant reduction in the lime standard fluctuations could be observed. This improvement in mixture control is due to several factors:

Control by the EO/RMP made use of data provided once a minute, allowing the MPC/MLD to utilize the full potential.

There is no sampling error due to a homogenization tank and the actual homogenization process in the tank.

Sample preparation errors are totally eliminated

Figure 10 shows how the EO/RMP reacts very quickly to the change in lime standard when the blending bed is changed. The changeover to the other blending bed is accompanied by a decrease in lime standard at the end and at the beginning of the blending beds. Thanks to the ability of the analyzer to react at one-minute intervals, the EO/RMP is able to immediately adapt the dosing devices of the silo conveyor scales to the situation and thus return the LSF to the required setpoint value within an extremely short period of time.

The extent to which the standard deviation of the LSF and other control parameters for the raw meal can be reduced depends strongly on the starting point of the extraction from the blending bed, the variability and the number of corrective materials, and the addition of alternative raw materials. As a rule of thumb, one can assume a halving of the standard deviation of the LSF, but in practice the reduction is normally even greater. A reduction of the standard deviation of the LSF to values around one (1) downstream of the mill have already been achieved by several systems using a combination of EO/RMP and online analyzer.

5 Cost effectiveness

6 Summary

Blending bed stacking and mixture control upstream of the mill are a single entity. Considering them as separate entities only results in minimal improvements. Isolated solutions must be avoided.

The selected online analysis system has to be able to reliably analyze the employed primary raw materials, as well as alternative raw materials, to the required degree of accuracy. If large quantities of alternative raw materials with no carbon content are fed to the blending bed, it is no use installing PGNAA systems.

The mixture control system has to be able to react variably to a number of influencing parameters. Normally, this fact totally excludes the use of PID-supported rigid control loops.

The effectiveness of a mixture control system is primarily defined by the quality and speed of its online analysis system, which captures the data and calculates the control parameters, such as lime standard and other control moduli.

The decision-making process has to take proper account of the cost effectiveness of the analysis systems being considered.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.