Energy-efficient cement production using

an extremely coarse raw mix – Part 1

A field test has demonstrated that energy can be saved and production increased using the coarse grinding process.

1 Introduction

A new and energy-efficient method, involving simultaneous determination of the optimum operating parameters for production of cement by means of intelligent linking of process operations, has been tested with the aim of optimizing the plant. This process is founded on the possibility of also achieving higher raw mix reactivity by extremely coarse grinding [4–14]. This potential can be attributed to the profound controlled generation of minerals thus initiated and to the resultant increase in the quantity of clinker melt in the sinter zone of the kiln and the reduction of its formation temperature. The greater quantity of clinker melt at low temperatures then causes mineral formation to proceed significantly more rapidly.

Energy consumption needed for grinding of the raw mix reduced by as much as 25 to 70 %.

Fuel requirement for burning of the clinker reduced by up to 15 % thanks to a low clinker-melt formation temperature, significantly improved heat transfer between the heating gases and the product in the transition zone of the kiln and the cyclone preheater, and a reduction in heat losses.

The degree of recuperation of clinker (Fig. 1) heat increased by 5 to 8 % by means of a narrower clinker-particle size spectrum, which stabilised primarily between 10 and 20 mm.

Raw mill output increased two- to 4.5-fold.

Kiln throughput raised by up to 30 %.

Specific abrasion of metal from the grinding media and mill armouring during raw-materials grinding reduced by 25 to 70 %.

CO2, CO and NOx emissions cut by up to 10 %.

Fine particulate emissions from the kiln and grinding facilities lower by up to 25 to 50 %.

Noise level during operation of the tubular and ball mills was reduced by 25 to 70 %.

Improved clinker grindability, thus raising the cement mill’s throughput by 10 to 20 %.

Maintenance costs reduced by 20 to 40 %.

2 Operational experience at an Austrian plant

with a DOPOL® heat-exchanger kiln

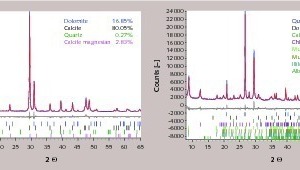

Due to the fine distribution of the quartz content in the marl, preconditions for the innovative coarse grinding technology appeared to be optimum, with the result that the management decided to start tests based on coarse grinding technological principles. The test objective was that, firstly, of determining the operating parameters necessary for this novel clinker burning process, and of evaluating its cost-efficiency for the plant. The question of whether and, if so, in what magnitude, investments in modification of the available facilities would be necessary was also to be clarified. Analysis of certain chemical and mineralogical parameters of the current feed material mix was firstly required for this purpose.

Drafting of the most important operating parameters for preparation of the raw mix using the new and energy-saving process was to be performed in addition to the quantitative XRD and microscopic analyses of the limestone and clay marl feed materials described below.

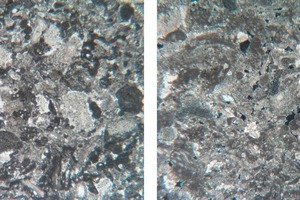

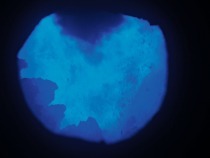

The light-coloured limestone (Figure 4) has a dense structure, but contains open cavities (porosity). Open porosity in the area of the section is around 3 Vol. %. The micrite:sparite ratio is around 10:90 by volume. The “groundmass” (matrix) of the limestone is therefore sparitic. The micrite appears in individual components. The carbonate components have an average particle size of 0.3 to 0.4 mm. The sample also contains isolated particles of quartz.

This sample can be regarded as fossil detrital limestone with a sparitic matrix (typical of depositions on the periphery of the reef, where limestone facies can change rapidly even within one quarry).

No apparent porosity is visible in the sample of the darker clay marl (Figure 5). Here, quartz particle size extends up to 200 µm. Quartz content in particles of above 80 µm is lower than 3 %vol. of the area of the section. The majority of quartz particles are smaller than 50 µm. It can thus be deduced that, in view of their particle size, the quartz particles present in the clay marl will have practically no relevant negative effects on solid-state reactions. Small muscovite and numerous small tourmalines can also be identified in the ultra-fine particled clay matrix.

Concerning the properties in use the rock’s microstructure can be summarized as follows:

Microscopic analysis confirms that the limestones and clay marls examined are well suited for both existing and for new, energy-saving technologies.

The limestone contains a small and non-relevant quantity of quartz particles.

The open porosity of 3 %vol. in the limestone provides good preconditions for infiltration of the high-SiO2 melt generated at <1200 °C into the coarse CaO particles and for their subsequent breakdown into small aggregates.

The quantity of 3 % of quartz of particle sizes above 80 µm present in the clay marl has for practical purposes no relevant negative effects on reactivity in solid-state reactions.

3 System configuration

4 Raw mill

It was decided, inter alia, on the basis of the test results obtained from the grinding plant, to route the coarse particles removed from the mill waste gas in the air separator entirely to the product.

Mill output firstly rose by around 8 t/h (14 %), from 57 to 65 t/h, after completion of these modifications. The screen residue on the 0.09 mm screen for the raw mix was increased from 10 to 12 % in the conventional process to around 30 to 32 % for the new process. It became apparent here that grinding rate was not limited by noise levels or by the bucket elevator, but needed, instead, to be adjusted manually, due to the falling temperature, to a minimum mill waste gas temperature of 80 °C. The recirculation factor for the material in the mill was around 1.

The quantity of breeze for return for regrinding following grading in the conventional air classifier was 28.8 t/h (without the air separator). The coarse material removed from the gas in the air separator amounted to 17.6 t/h and was routed to the product using a common air slide for preparation of the raw mix. The recirculation factor for a fresh material feed rate which had increased from 57 t/h to 65 t/h thus fell from 3 to 4 for conventional fine grinding (28.8/65) to 0.44 for extremely coarse grinding. This constitutes an enormous relief for grinding of the mix in the grinding system. Despite the fact that mill output increased by 14 %, the overall feed rate into the mill (fresh material + breeze and coarse material) of 256.5 t/h for conventional fine grinding fell to 93.6 t/h, with a recirculation factor of 3.5, for extremely coarse grinding. The result is significantly reduced energy consumption and significantly lower wear on the conventional air classifier and conveying equipment.

Distribution of the breeze removed in the conventional air classifier for subsequent return for regrinding was 10.8 t/h to the first chamber and 18.0 t/h to the second chamber, at a valve setting of 50 %.

Grinding output increased to up to 71 t/h (i.e., by 24.6 %) after cleaning of the gas line; noise measurement/bucket elevator intervention still remained unnecessary. The temporarily blocked slots of the mill outlet plate may have had a limiting effect here. The temperature limit for the mill waste gas, a factor restricting mill output, was maintained manually at 80° C. Raw stone feed was used for regulation purposes. Figures of 2.17 to 5.6 % were indicated for raw stone moisture content.

The bulk density of the extremely coarse raw mix was 1200 kg/m³, compared to 900 to 950 kg/m³ for the conventional fine raw mix. This increases the capacity of the mixing silo by 25 %.

A frequency converter for the mill fan was installed to permit higher hot gas feed rates into the mill and thus achieve more efficient drying. The slots in the raw mill outlet plate were cleaned simultaneously; they had been practically completely blocked by inclusions of metal originating from the (recycled) foundry sand. Output from the mill after restarting was then initially 70 t/h. Screen residue on the 0.09 mm screen was now 28 to 32 %.

The mill output was around 70 to 73 t/h with no increase in fan speed. Mill waste gas temperature at this time was approx. 92° C. Fan speed was then increased, and mill filling level reduced from 34 % to 32 %. Mill output then rose to 76 to 79 t/h, while mill waste gas temperature fell to 86° C. Screen residue on the 0.09 mm screen remained 28 to 32 %, and mill output continued to fluctuate between 76 and 80 t/h. Energy consumption for extremely coarse feed material grinding dropped by 14 to 40 %, proportionally to the increase in mill output.

Further provisions to increase the capacity of the mill conveying routes would be necessary in order to achieve the optimum screen residue of 40 to 50 % on the 90 µm screen as determined in the laboratory tests. This would have permitted an additional increase in the output of the grinding and kiln installations and, simultaneously, further power and fuel savings.

As expected, the temperature of the mill waste gases falls more strongly in conventional fine grinding than in the case of extremely coarse grinding. This can be explained as follows:

As is generally known, not only free water, but also water of hydration/crystallisation and water adsorptively fixed to the surface may be present in the crystalline matrix. The quantity of water adsorptively fixed to the particle surfaces is proportional to the total particle surface and increases proportionally as particle fineness increases. The water content for an adsorptive layer of water of 1*10-6 mm =10 Å thickness is greater by a number of tenths of a percentage point in the case of conventionally finely ground limestone with a specific surface area of 0.35 to 0.42 m2/g and a particle size of 0.1 to 300 µm than in the case of extremely coarsely ground limestone with its specific surface area of 0.10 to 0.14 m2/g and particle size of 0.1 to 3000 µm. This fact could, at least in theory, result in noticeable evaporation energy savings.

The molecular forces of attraction of the particles exert pressure on the adsorptively fixed water, with the result that it exhibits an increased density (around 1.03 g/cm³), a greater resistance to evaporation and thus a higher evaporation temperature. The result is that proportionally more of any quantity of free water remaining in the grinding stock during the grinding and drying process is adsorbed by the greater surface area occurring in conventional fine grinding, and that more energy is thus required for evaporation of the water.

5 Conclusion and prospects

It very quickly became apparent that the coarse grinding process was capable of achieving a significant increase in raw mill production but, on the other hand, that problems occurred in conveyance of the breeze in the aeroslides downstream of the conventional air classifier.

The considerable increase, of up to 40 %, in mill output can also be regarded as a largely substantiated result.

The grinding system output increased by 40 %, from 57 to 80 t/h, while power consumption fell by 45 to 50 %, referred in both cases to the kiln output increased by 22 to 30 %, with only limited performance reserves in the conveying equipment.

At 30 to 32 % screen residue, the grinding plant is able to continuously maintain a throughput of 80 t/h. Outputs of above 100 t/h are conceivable, given a further increase in screen residue, but cannot be handled by the existing conveying systems.

Acknowledgement

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.