Neutron activation as an online procedure in cement plants

The use of PGNAA (Prompt Gamma Neutron Activation Analysis) makes it possible to determine the content of the components in bulk flows in cement plants directly online on the conveyor belt. The nature of the excitation and radiation means that the material can be penetrated even with large layer thicknesses on the belt.

Introduction

X-ray fluorescence analysis is the classical method for determining the elements in a cement plant. As a...

Introduction

X-ray fluorescence analysis is the classical method for determining the elements in a cement plant. As a multi-element procedure this enables the important elements to be determined directly in the solid material after the sample has been ground, blended with a binder and pressed into a tablet. The disadvantage of this method lies in the selective sampling. Relatively small amounts of sample have to be taken from a large material flow and prepared, and these are then supplied to the measuring system. A precondition for representative information about the material content is the homogeneity of the material, which is naturally only present to a limited extent. The sampling and sample preparation also leads to a certain time delay in transmitting the results, with the result that it is not possible to react immediately to changes in composition.

Neutron activation has now been established for some years as a rapid method of direct determination of the elemental content on the conveyor belt. When set up correctly it can help to check the entire material flow. This leads, for example, to optimization of the quarry by selective choice of different grades, to minimization of the deviations in the blending bed and ultimately to improved, corrected compositions of the material flow before the raw mill (Fig. 1).

Neutron activation is the ideal solution for online analysis because it is capable of penetrating large sample thicknesses for analysis. Neutrons can be generated either by a radioactive source (radionuclides) or by a “neutron tube” that only generates neutrons on demand. The idea of a source that can be shut off is interesting not only from the safety aspect but also because it can lead to longer usability and greater stability.

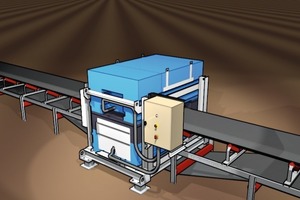

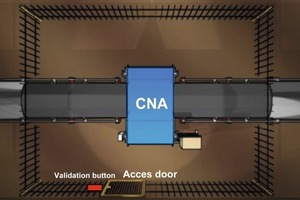

There are no moving parts in the spectrometer itself; only the belt conveyor moves. The results are transmitted online to a Distributed Control System (DCS). Individual components, cumulative parameters or derived quality parameters, such as the lime saturation factor, can be passed on to the control room. The CNA (controlled neutron analyser) system described below has been developed and built in France by Sodern, an EADS company. Marketing and servicing are carried out exclusively by the worldwide network of PANalytical.

Multi-element analysis

With X-ray fluorescence (XRF) analysis the excitation takes place very effectively in the atomic union (e. g. solids) by exciting the inner K electrons (using Bohr’s atomic model). However, the escape depth of the element-specific X-ray radiation out of the sample is depending on its specific energy and on the absorption of the concerning sample at that specific radiation energy. The escape depth of light elements like Na and Mg is only a few µm and it is correspondingly less for even lighter elements.

If greater sample penetration is required then even higher energy primary excitation and resulting electromagnetic radiation are needed. Energy-rich neutrons can penetrate correspondingly deeply into the sample and produce excited states there in the atomic nuclei that can be stabilized again by the emission of energy, e. g. gamma radiation. The gamma radiation can then be identified spectroscopically and used in this way for quantitative determination of the content of the components. The escape depth of the gamma radiation is significantly greater and permits far-reaching penetration of the material being transported on the conveyor belt. Neutron activation analysis is therefore ideal for direct online analysis on a loaded belt.

PGNAA (Prompt Gamma Neutron Activation Analysis)

It should be mentioned that neutrons generated by radioisotopes as well as by neutron tubes are high energy neutrons (neutron tube 14.1 MeV). These neutrons are initially scattered elastically and non-elastically in the sample and the external shield. This slows them down, i. e. they lose energy and, in the case of non-elastic scatter, the excited nucleus emits gamma radiation. This cannot be used profitably for determining the content of the components. However, the thermal neutrons that have been slowed down can be used for efficient excitation of atoms.

In classical neutron activation analysis the atomic nuclei are changed in such a way that, for example, an element with a higher atomic number is produced with the emission of very diverse radiation (alpha, beta, gamma radiation). However, as a rule this process is not spontaneous and may take a long time (half-life period). This radiation is not suitable for use in online spectrometers because, with transport speeds that are sometimes several metres per second, it is not directly possible to identify the radiation from the sample that happens to be in the spectrometer area. However, some elements generate absolutely instantaneous signals, although these are minimized by suitable measures (see below).

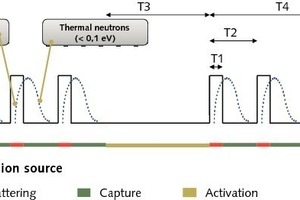

The prompt gamma radiation used for determining the content is generated by exciting the samples with the thermal neutrons already described (<0.1 eV) (Fig. 2). These are produced either in the sample itself or in the spectrometer shield made of synthetic material (polyethylene or paraffin). The efficiency of the scattering is particularly high here as the synthetic materials consist to a great extent of hydrogen, which has the greatest moderating effect on the energy-rich neutrons.

With this method there is no need for a source that can be operated permanently in situ, in contrast to classical neutron activation, in which the sample to be measured is irradiated over a fairly long period with a high flux density (in large nuclear reactors) and which even permits trace element analysis with fairly long residence times. Historically, two types of source have developed: permanent radionuclide sources and interruptible deuterium/tritium sources.

The first, and older, type uses a radionuclide that releases neutrons continuously through radioactive decay. Cf252, which can be used as the oxide (Cf2O3), has gained acceptance here. The radionuclide is produced in nuclear reactors from uranium and plutonium by several successive neutron captures and beta decays. The average energy of the neutrons is 2.1 MeV. The half-life period is 2.6 years, i. e. the neutron flux density is halved after 2.6 years. This means that part of the activity of the permanent emitter has to be replaced in accordance with a time plan. However, the reliability of supply of this material no longer seems secure in the long term, which has a direct effect on the costs.

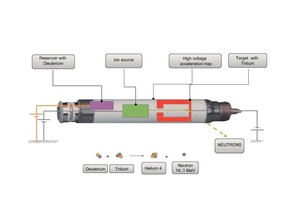

The newer process enables neutrons to be generated on demand (Fig. 3). This utilizes the fusion of deuter-ium and tritium to form helium with the emission of a neutron.

In simplified form the process proceeds as follows: from a reservoir of deuterium that is combined with a metal oxide the deuterium can be made available reversibly on demand and ionized. The charged particles can then be accelerated against a cathode by applying a high voltage. This cathode contains tritium, combined in a similar form, that enters into a fusion reaction with the energy-rich deuterium. This generates neutrons in addition to helium. This method only generates neutrons when the high voltage is switched on.

The tube is supplied by reservoirs of deuterium and tritium so the consumption, and therefore the service life, are determined by the operating times: the less the source is used the longer it lasts. The typical service life of a Sodern deuterium-neutron source is about 12 000 h.

The NEM (neutron emitting module) is totally enclosed and has a casing of stainless steel. It can be switched off and removed from the system after a short waiting time due to the intrinsically low activation level of the enclosure (Fig. 4).

Another advantage of the deuterium source lies in the stability of the neutron flux. With a radionuclide there is a continuous reduction in the neutron flux due to the half-life period but a constant flow of neutrons can be obtained by optimizing the high voltage setting of the NEM. This is permanently re-adjusted by an independant neutron measurement.

Pulsed source

By pulsed neutron generation (Fig. 5) it is possible to reduce or minimize the disruptive effects. Rapid neutrons are generated initially by a short pulse in the µs range. This is where the majority of the scatter radiation occurs. After moderation with the sample and the equipment casing made of synthetic material these are slowed down to thermal neutrons of low energy (<0.1 eV) that are therefore usable for analytical purposes. The time period for this reaction without the generation of new neutrons also lies in the µs range but is longer than the initial pulse.

This process is repeated many times until a “longer” period without pulse is obtained. During this time period the classical activation (that with some elements can also occur after a short time) is measured in the form of gamma radiation. The entire process is then repeated continuously.

The respective spectra are recorded from all three sources of radiation. This naturally leads to a large quantity of information. In the subsequent output of results, and also because of the significantly better count statistics, a result in the form of concentrations of individual components, cumulative parameters or derived variables is output only approximately every minute.

The detector for the gamma radiation is a crystal that is sensitive to this radiation – a BGO (Bi4Ge3O12) detector. This has a very high level of stability and longevity. The resolution is 250 keV at 5 MeV. Two detectors can also be used simultaneously for very wide conveyor belts or to improve the count statistics.

Structure of the spectrometer

The side angle of the conveyor belt is also important. Another criterion is the consideration of the “tunnel height”, i. e. the distance of the upper shield of the unit, and therefore of the overhead detector, from the conveyor belt. This can be important in, for example, applications such as quarries so that quite large lumps can pass through the system.

In every case the belt width, belt angle and tunnel height are important variables for the geometry that have to be taken appropriately into account. The actual loading of the belt is determined by an upstream belt weigher (in conjunction with the belt speed). The moisture content of the sample can be deduced from the hydrogen signal, which in this case is caused only by the water. All these variables are factors for the effectiveness of the unit and can be used in advance to calculate the performance of the unit. There are no moving parts in the system apart from the conveyor belt (Fig. 6). The contact between unit and belt is through slider plates made of synthetic material that can be replaced as required.

The NEM is inserted into the lower part of the spectrometers and is therefore located under the conveyor belt. The detector is in the upper part, above the belt. Both modules are enclosed. Supply and communication lines lead to an external supply cabinet.

Calibration

The net signal is taken as the measured signal from the standard after subtraction of the signal from the empty sample chamber. In spite of the high resolution and sensitivity of the detector it is still not possible to determine all signals in isolation without overlapping lines. The evaluation process for obtaining the extended net signals while taking the influencing factors into account is therefore complex and can be successful for element peaks only by weighted consideration of different parts of the spectrum. However, when correctly applied this leads to very stable and reliable values.

After the unit has been installed at the place of use selected standards are used once again for re-calibration so that small changes can be taken into consideration in situ. The calibration is retained for a long period because the neutron flux is kept constant.

The analysis

Table 1 shows typical performance data from a static test under given (usual) system conditions. A distinction is made between the repeatability relative to a single sample (measurement time two minutes with five repetitions) and the standard deviation of the accuracy of five different samples (measurement time of one hour per sample). These values have become accepted as standards as there are no certified reference materials available for comparison purposes because of the large sample quantities.

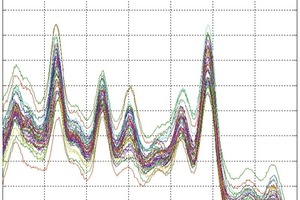

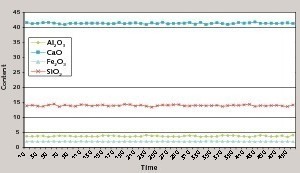

A clear representation of the concentration behaviour pattern of dynamic measurements is shown in Fig. 8 where the behaviour with time (average values of individual results) is shown for the main components in the form of oxides. More serious inhomogeneities in the quarry lead to greater fluctuations in the individual results.

Safety

Conclusions

The use of interruptible and pulsed neutron sources has made routine industrial application of neutron activation significantly easier. During the development the durability of the tubes has been drastically increased with the result that interruptible sources are also the most efficient solution in the majority of applications. The pulsed excitation provides more selective information for a better signal/noise ratio of the signals.

PGNAA has no moving parts. The only contact with the conveyor belt is through slider plates that are made of synthetic material and can be replaced annually. This reduces the amount of maintenance for the entire system to a minimum. The data can be sent directly to a master computer for optimizing other processes or improving mixtures.

In every case the entire quantity of bulk material being transported on the belt is examined. This means that sampling and sample preparation play no part and there is no longer any concern about achieving homo-geneous and representative sample taking.

A large number of cost savings can be developed. In the last few years the technology has become widespread in the cement industry and in mineral mining. The large, and sharply rising, number of installations is evidence of the profitable safety and reliability of the method.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.