Production cost saving by using coarse alternative fuels

Faced with rising primary fuel, oil, gas, coal or pet coke prices, as well as challenging market conditions, cement plants around the world are looking for ways to reduce their cement production costs.

1 Introduction

Many cement plants in Europe began burning alternative fuels in the main burner many years ago. Because the fuel must be transported pneumatically into the main burner and the particle residence time in the kiln at the main burner is quite short, the fuel must be fully prepared. Independent of the feeding, a gravimetric dosing device is mandatory and its accuracy should increase with the substitution rate.

2 General challenges in dosing secondary fuels

Compared to other raw materials and primary fuels, solid alternative fuels tend to be more difficult to handle: material...

1 Introduction

Many cement plants in Europe began burning alternative fuels in the main burner many years ago. Because the fuel must be transported pneumatically into the main burner and the particle residence time in the kiln at the main burner is quite short, the fuel must be fully prepared. Independent of the feeding, a gravimetric dosing device is mandatory and its accuracy should increase with the substitution rate.

2 General challenges in dosing secondary fuels

Compared to other raw materials and primary fuels, solid alternative fuels tend to be more difficult to handle: material characteristics vary widely in particle size, moisture and density. The fact that this kind of material often is flaky, fibrous and compressible, does not make the feeding and dosing any easier. It is also likely that material sources will change over the course of the year and therefore the type of fuel also changes frequently.

In the year 1997, FLSmidth Pfister has overcome this issue by inventing a multi-fuel system that is capable of handling a wide variety of secondary fuels such as fluffy, refuse derived fuels (RDF) like plastics, car shredder, industrial waste, municipal waste, rubber/tyre chips, biomass, or impregnated sawdust, sewage sludge, wood chips, wood waste or meat and bone meal. Rotor weighfeeder Pfister® TRW-S/D has proved its reliability in many applications and with a vast array of materials and densities ranging from 0.05 t/m3 up to 0.8 t/m3.

3 Installation possibilities

The multi-fuel FLSmidth® Pfister® Rotor Weighfeeder system can be installed in different places and in nearly all variations of alternative fuel installations (Fig. 1). Its application ranges from simple trial or truck docking stations. or any kind of silo installations, leading up to large storage halls, and it is suitable for pneumatic material feeding to kiln burners, or mechanical material transport into calciner inlets.

4 Dosing of coarse material

A lot of equipment and electrical power is necessary for producing fully prepared SRF (Fig. 2). Therefore, the price of such fuel, for main burner firing for example, is much higher than coarse RDF, which is only prepared for calciner firing. As a result, there is a growing trend to use lump sized materials where less preparation is necessary. This offers high potential cost savings for cement plants. A brief outline of some of the projects that FLSmidth Pfister successfully executed together with its clients is provided below.

In 2009, FLSmidth Pfister delivered a rotor weighfeeder Pfister® TRW-S for dosing up to 15 tph of coarse RDF for calciner firing in Ireland. The material size was up to 100 x 100 mm, with a bulk density of 0.07-0.3 t/m3 (Fig. 3). Although using the coarse RDF, FLSmidth Pfister successfully installed pneumatic transport running from the dosing equipment into the calciner.

Figure 3a shows an FLSmidth® Pfister® rotor weighfeeder located in Germany, which has been in operation for more than five years. In this case, the weighfeeder mechanically doses up to 10 tph of coarse RDF into the calciner. This plant initially began using fully prepared RDF, but due to the fuel price, the plant has only been using medium calorific material for the last few years. This RDF has a regular 2D-size of up to 100 x 100 mm. However, it also includes oversized material, such as long strips of up to 1000 mm and other foreign bodies, e.g. pieces of metal up to 100 x 50 x 50 mm (Figs. 3b, 3c). Due to its design, the rotor weighfeeder is working well with the described material.

In Brazil, the same rotor weighfeeder Pfister® TRW-S doses tyre chips (Fig. 4) with a bulk density of 0.7 t/m3 into the calciner. The rubber chips are up to 100 x 100 x 30 mm in size, plus overlapping steel wires and some oversized parts. It has a capacity of up to 12 tph.

5 Test centre

In 2012, FLSmidth Pfister carried out test runs on several different materials in one of its two test centres. These tests included the following specifications (Figs 5a, b, c):

a. Bulk density: 0,152 t/m3, material size:

200 x 50 x 50 mm, max. mass flow: 25 t/h

b. Bulk density: 0,048 t/m3, max. length:

150 mm, max. mass flow: 25 t/h

c. Bulk density: 650 kg/m3 with foreign bodies:

Big-bag-stips 2000x200mm

Some textiles, like clothing

Some rubber-chips, size 300 x 200 x 30 mm

Some pieces of wood 100 x 100 x 30 mm

Some plastic bottles, some were still filled

Some coarse plastic parts, up to 300 x 300 x 10 mm

Main parts: wet peat, wood-chips (see above), straw from corn, 200 mm long; max. mass flow 25 t/h

The results of the tests strongly attest to the elaborate design of the rotor weighfeeder Pfister® TRW-S/D. This dosing system has a very robust construction and the design prevents blockages even if foreign bodies are included in the material. The ability to feed almost all kinds of solid alternative fuel is complemented by FLSmidth Pfister’s experience in the field. More than 230 units have been sold worldwide.

6 Operating principle of the multi-fuel

dosing system

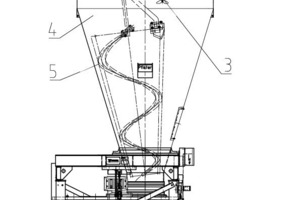

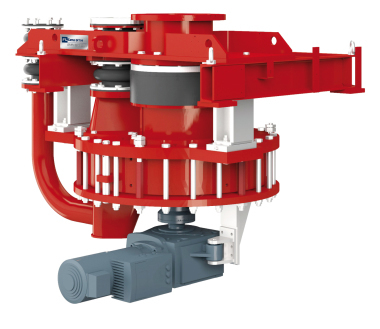

The rotor Weighfeeder Pfister® TRW-S/D is a fully enclosed continuous gravimetric dosing system that can be internally compared with a circular chain conveyor. Figure 6 illustrates the components of a multi-fuel dosing block. The fuel is fed from the storage location via a pre-feeding system (1) into the calibration hopper (4), which is equipped with a stirrer (5) and with a level sensor (3). The eccentric located stirrer (5) lifts and homogenizes the material, loosens it up and lets it flow freely out of the pre-hopper on the opposite side of the outlet into the rotor weighfeeder Pfister® TRW-S (6). This means that the material will never be pressed, which is very important for a stable flow. Static load cells (7) integrated into the frame enables an online calibration during operation and can allocate the pre-hopper content in real time.

7 Operating principle of rotor weighfeeder

Pfister® TRW-S/D

As demonstrated in Figure 7, a FLSmidth® Pfister® rotor weighfeeder feeds the material in a circular direction with radial scrapers (6) and circulating through walls (7). The bulk material is extracted directly from the homogenization hopper by the rotor wheel via a feed chute (1) with a layer height limiter. Reliable extraction of the bulk material out of the homogenization hopper and controlled, slip-free transport of the bulk material over the base plate (5), as well as the measuring system, is ensured by the side walls, which circulate along with the scrapers. The rotor wheel is supported by the central drive so that it can tilt and move vertically. Part of its load is taken by laminated spring strips. The wheel rests on the base plate so that it can float and rotate. This virtually rules out any jamming of the rotor by oversized parts of the bulk material or foreign bodies. The material is carried over the weighing section and fed directly into the process.

8 Weighing principle

The fuel that is transported by the rotor from the inlet (1) to the outlet (2) produces a moment around the weighing axis A-A. The weighing axis is located through both bearings (A to A). This weighing axis is eccentric to the rotor shaft but through the middle of both the inlet (1) and outlet (2). This produced moment is measured by the load cell device (3). The measured value provides information on the bulk material mass in the rotor weighfeeder before material discharge. The loading of the rotor weighfeeder with the related rotor position is stored by the weighing electronics.

The weighing electronic calculates the required speed of the motor (4) for the time of the discharge with the specified output feed rate and the measured bulk material mass. This means that the speed of the rotor is controlled inversely to the loading of the rotor at the outlet (2). With the state-of-the-art proactive control strategy ProsCon®, the weighfeeder fulfils the high requirements for stable fuel dosing with high short and long-term accuracy and ensures outstanding burning conditions.

9 The benefits of this construction are listed below

Completely dust tight: the FLSmidth® Pfister® rotor weighfeeder is a completely closed unit. This prevents environmental pollution and the emission of dust or odours.

Maintenance work regarding the TRW-S/D is kept to a minimum as all parts that come in contact with the fuel are made of steel and there is only one rotating part – the rotor wheel itself.

Fuel homogenization bin: the pre-hopper stirrer to ensure a consistent fuel quality. Secondly, it ensures a steady loading of the rotor weighfeeder even if there is a short interruption to the material supply or if the pre-hopper is fed over a long distance.

Stable design and avoids blockages: the discharge aid in the pre-hopper – the stirrer – lifts the material, so that it is not compressed and will continue to flow out of the pre-hopper. The smallest gap inside the TRW-S/D is between 150 mm and 450 mm (depending of the size of the device), see Figure 7. This is one of the reasons why Pfister®´s TRW-S/D is well designed for coarse materials. In some other feeding systems (e.g. screw feeders) the gap between a screw and its housing is normally only 10-30 mm.

Available with ATEX-certificate and in explosion proof design: some alternative fuels, such as sawdust or sewage sludge, are flammable and as a result an explosive atmosphere could be created if mixed with air. In some countries it is necessary to have explosion-proof equipment when handling such dangerous materials.

High feeding accuracy: high accurate feeding of fuel is the basis of stable kiln operation. When dosing secondary fuels, the fact that very light materials, such as plastic, are difficult to measure because of their extremely low gravimetric force has to be taken into account. FLSmidth Pfister has overcome this problem by measuring a material layer of up to 500 mm in the feeder without the risk of material spilling. The relatively large mass of bulk material in the rotor weighfeeder leads to a high momentary load in the measuring section of the feeder. In combination with prospective control ProsCon®, a high and stable dosing accuracy is achieved. Along with high mechanical reliability, this ensures constant kiln firing.

10 Conclusion

Stable and accurate dosing of secondary fuels is one of the key elements required to produce clinker profitably and efficiently. With its multi-fuel rotor weighfeeder Pfister® TRW-S/D concept, FLSmidth Pfister is offering a future-oriented technology that can dose up to 25 t/h (with 0,07 t/m3). With more than 230 installations worldwide, customers of FLSmidth Pfister are feeding many tons per year of solid secondary fuels.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.