Increase of V-separator efficiency

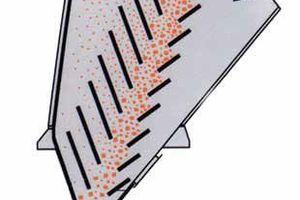

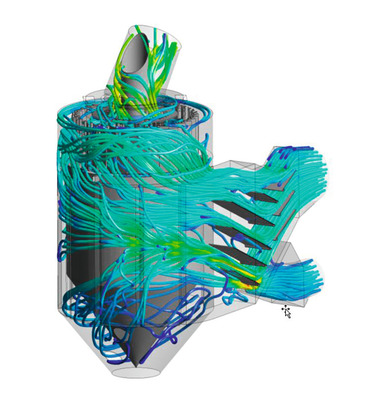

The V-separator has been widely adopted for processing of comminuted material, mainly for closed circuit systems with roller press. It is a really static and energy-saving apparatus that has high reliability in operation. It also carries out the function of disaggregation of material cakes after compacting by the roll. The cakes fall down by the slanted step grate of the separator. They are then divided into parts and scavenged by transversal airflow. Small parts are carried by flow to the top separator output and the coarse parts fall down and return back to repeat destruction.

However, the...

The V-separator has been widely adopted for processing of comminuted material, mainly for closed circuit systems with roller press. It is a really static and energy-saving apparatus that has high reliability in operation. It also carries out the function of disaggregation of material cakes after compacting by the roll. The cakes fall down by the slanted step grate of the separator. They are then divided into parts and scavenged by transversal airflow. Small parts are carried by flow to the top separator output and the coarse parts fall down and return back to repeat destruction.

However, the disaggregation properties of the dynamic separator are better than the V-separator due to the advantage of the centrifugal force in comparison to the gravitational force. That is why it is necessary to improve the disaggregation of the crushed material inside the V-separator in order to increase its efficiency. The achievement of this is now possible with the use of the electro-neutralization technology according to patent DE 698 09 251 T2.

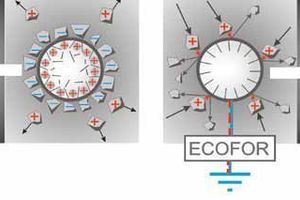

The process of comminution of a solid body is not only a mechanical process of its destruction, but is also accompanied by an electro-physical phenomenon due to the breaches of the double-electric layers of the contacting phases of such material. The fresh surface of the comminuted material dynamically becomes unstable and statically charged. As a result, an electrical charge appears on the surface of the particles that are the cause of the adhesion process between them.

The cakes of pressed materials have many cracks inside between particles of different sizes. Some of the cracks in the small-sized particles cannot be opened inside a separator due to adhesion. These particles adhere to the large ones and decrease the efficiency of the separator. The adhesion force has components of electrostatic and intermolecular interaction. If the electrostatic component is reduced, adhesion of the small particles is also decreased and the separator´s efficiency is improved.

Prevention of the effect of the electrostatic adhesion is carried out by the active neutralizer electrostatic device Ecofor (Fig. 1). It is connected to the metal of the coupling flange of the material feeding of the V-separator (Fig. 2). A positive electrostatic charge of comminuted material is actively discharged by an active neutralizer and conducted in grounding whilst the material falls through the slanted metal step grate. As a result, an additional part of the small-sized powder is passed by the same airflow to the finish ball mill or its separator.

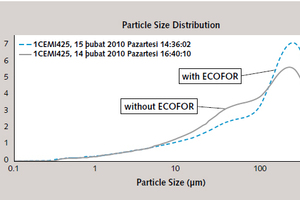

In 2010, this type of test for electro-neutralization of comminuted material inside a V-separator was carried out in Turkey at AkcanSA Cimento (Büyükçekmece). During the test, particle size distribution of the returned fraction after the V-separator was analyzed by the laser granulometer. The load of the return transporter was also checked and became less during one hour after turning on the active neutralizer. The comparison of the particle size distribution for the returned fractions under stable conditions of roller-press (Fig. 3) has enhanced that part of the particles in size range from 10-100 µm, which was decreased by 22 % under active neutralizer influence. These particles were transported by the airflow to the finish mill but not, as before to repeat crushing once again. This efficiency improvement has enabled an increase in capacity of the grinding systems of the cement plants AkcanSA from 125 to 140 t/h, Mardin Oyak Cimento from 102 to 110 t/h and CimSA Nigde Cimento from 128 to 138 t/h.

V-separators are often successfully used for grinding. Now their efficiency can be increased by active neutralizers not only for new deliveries but also for exploited grinding systems.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.