High-efficient cement manufacturing with POLYCOM® and SEPOL® PC – Machine and System Concept –

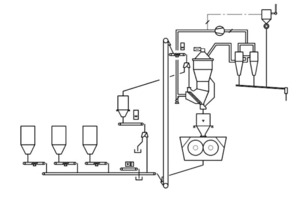

For cement grinding, the high-pressure grinding roll (HPGR) POLYCOM® and the static-dynamic separator SEPOL® PC can be installed as a finish-grinding circuit or, in combination with a ball mill, as a combi-grinding system.

1 Introduction:

1 Introduction:

As a result of the continuous optimization of the overall machine concept, HPGRs POLYCOM® can be integrated into both new and existing grinding plants without any problem from either the process technological or plant engineering points of view. Since 2009, ThyssenKrupp Polysius has received 17 orders alone from India for combi-grinding systems involving a POLYCOM® and SEPOL® PC combination. These orders concerned both new plants and retrofits designed to increase the capacity of existing ball mills. In the fourth quarter of 2011, the first of these systems was successfully commissioned. This involved an extension of an existing ball mill with a warranted grinding capacity increase from 100 tph to approx. 300 tph. The title picture shows this grinding system extension at a plant in Chanderia, Rajasthan/India.

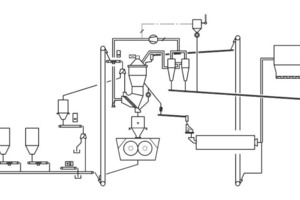

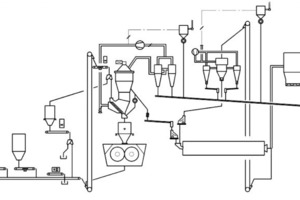

Modern POLYCOM® grinding systems consist of the high-pressure grinding roll and the static-dynamic separator SEPOL® PC. This newly developed SEPOL® PC is the combination of a very compact static cross-flow separator with the high-efficiency separator SEPOL® LM and can be used as a combined separator for the POLYCOM® and the ball mill. This separator concept was specially developed for use in a grinding circuit equipped with an HPGR. The circulating material from the ball mill can still be fed from above onto the distributing plate of the SEPOL® LM, which uniformly disperses the material through the separating zone. Fig. 1 shows a typical process flow sheet of a combi-grinding system.

2 High-pressure grinding roll POLYCOM®

To meet the demands placed on high-pressure interparticle comminution in a bed of material, such as:

long service lives of the roll surfaces,

energy-efficient production of fine material,

optimum draw-in of feed material, assuring maximum throughput,

very smooth running, in order to protect the machine and

easy replacement of worn roll bodies

large shaft diameter for absorbing the bending and torsional stresses,

bearings designed for safe and reliable operation,

optimum distance between bearings minimizing the bending moments,

thick roll tyres assuring safe shrink fits,

thick wear layers on the roll surface to assure long operating times and minimum wear costs.

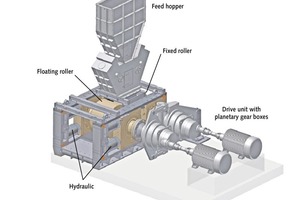

The fixed roll and the floating roll are mounted in bearing blocks, with that of the floating roll movably guided in the longitudinal direction. Skewing of the floating roll is compensated by the respective bearings. Depending on the size of machine, the grinding forces are transmitted to the floating roll by 2 or 4 hydraulic cylinders. A hydropneumatic spring system allows the setting of different pressure characteristics and material-specific control methods to enable optimum application of the grinding pressure in the roll gap and to protect the machine against possible overloading. The floating roll automatically accommodates changes in feed material characteristics by moving outwards or inwards.

In order to ensure uniform distribution of the drive power to the two drive motors, the vertical feed shaft can be equipped with infeed guide plates to adjust the distribution of material passing between the rolls. The material filling level is monitored with load cells installed at the POLYCOM® feed bin.

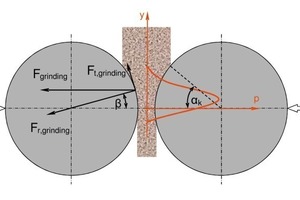

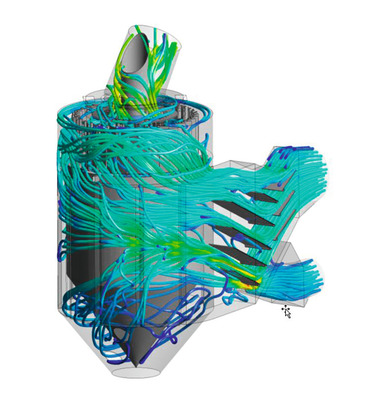

The high-pressure interparticle comminution of the POLYCOM® is based on the following principle: The brittle material is fed to the HPGR from a feed bin. The grinding elements are two counter-rotating rolls, between which the material is crushed. The required comminution pressure (up to 250 MPa in the gap between the rolls) is transmitted via the hydraulic system. The high-pressure interparticle comminution produces compacted cakes of material containing a high proportion of fines and with coarser particles showing extensive cracking. Whereas the grinding action of a ball mill involves a mixture of compressive and shear forces, the POLYCOM® imposes virtually pure compressive force on the layer of material between the rolls (Fig. 3). The resultant compression stress inside a particle is more than five times higher than shear stress would be.

In conventional closed circuit ball mills, the retention time of the material being ground is up to 30 min. The circulating material is not separated until it has been subjected to numerous grinding ball impacts. This results in overgrinding and a correspondingly large amount of ultrafine particles in the finished product. In contrast, the material retention time in the POLYCOM® is in the order of milliseconds. The circulating material is separated after just one comminution event. Unlike conventional ball mill systems, there is a strict segregation of grinding and separation processes in the POLYCOM® circuit.

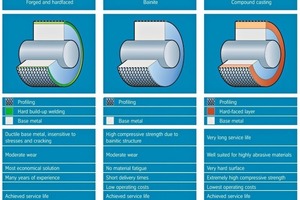

forged, hardfaced rolls,

chill cast tyres made of bainite and

chill cast tyres made of compound casting.

The profiles welded onto the grinding rolls have been optimized as a result of operational experience. They improve the material infeed behaviour and minimize the relative movement between the material being ground and the roll surface. This results in higher throughput rates and also extends the service lives.

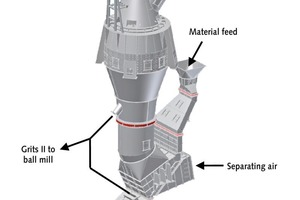

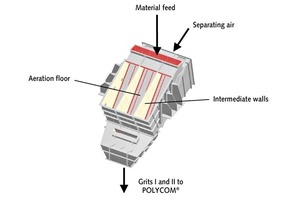

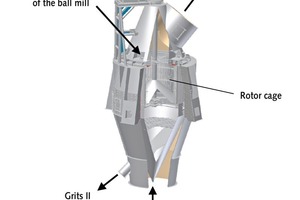

3 The static-dynamic separator SEPOL® PC

high separation efficiency with minimum construction height,

high achievable finenesses,

the ability to optimally guide the streams of material (feed material, finished material, grits) and

high wear resistance against coarse material in the compacted cakes.

The use of the aeration floor enables the very compact construction of the cross-flow separator. No horizontal baffle plates are needed; the unit is only equipped with vertical guide vanes to improve the material lifting performance of the separating air (Fig. 7).

4 Process technological system configurations

A new installation (Fig. 1) has the advantage that the POLYCOM® and the ball mill jointly use a single SEPOL® PC separator, so that only one product stream leaves the system. A shared separator also requires just one separating air circuit, from which only the dedusting air has to be extracted.

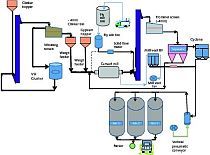

For increasing the grinding capacity of an existing ball mill (Fig. 10), the POLYCOM® circuit is installed upstream and the ball mill circuit including separator is generally left unmodified. In this case, the product is made up of the finished materials from the POLYCOM® circuit and the ball mill circuit.

5 Polysius plant design

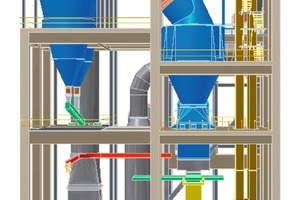

What if the static cross-flow separator is installed above the POLYCOM®?

Then the POLYCOM® is in a significantly lower position so that the high loads are closer to the ground, which greatly simplifies the execution of structures.

Only one bucket elevator is required for feed and circulating material.

No additional conveying equipment is needed for the feed material.

Because of the common conveying to the cross-flow separator, the feed material and the circulating material are optimally blended.

Furthermore, the mechanical conveying impacts lead to disagglomeration of the compacted cakes from the POLYCOM® and enable a significantly improved distribution of the feed material over the cross-section of the separator. This assures higher separation efficiency in the cross-flow separator.

The dynamic separator SEPOL® LM is directly connected with the cross-flow separator to form a compact separating unit.

Individual transition elements can be fitted to adapt both the cross flow separator and the dynamic separator to the respective requirements.

The grits from cross-flow and dynamic separator are thoroughly mixed and fed directly to the POLYCOM® feed system.

Then the HPGR is in a considerably higher position, making it necessary for the high machine loads to be supported far from the ground. This results in significantly more complex structures.

Additional conveying units are required for the fresh feed.

The very compact cakes of HPGR are fed directly into the cross-flow separator without further mechanical impacts. This and the poorer distribution over the cross-section of the separator have a negative effect on the separator efficiency.

Because of the construction volume of the cross-flow separator the recirculating bucket elevator has to be installed further away from the HPGR.

6 Flexibility of the grinding system

In order to achieve higher production rates or to manufacture several finished products simultaneously, several identical grinding systems can be installed. For instance, one grinding system could produce CEM I with clinker and gypsum while another grinding system produces granulated blast furnace slag, each with process conditions optimally adjusted to the respective feed materials, and the products are subsequently blended to make CEM II. This solution has the additional charm of minimizing the cost of the spare parts inventory.

The construction of identical but separate grinding systems assures greatest possible flexibility, operational reliability and plant availability. The process technological separation of the systems applies to both the grinding and the separation process. In case one system is shut down for maintenance, the others continue their independent operation.

Installing several separate grinding systems allows each one to be operated with optimum process technological conditions. This results in high energy efficiency and thus minimizes the energy costs and environmental impact in comparison to conventional closed circuit ball mills.

7 Summary

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.