Ressource conservation and process efficiency: 100 years of experience

During the last few years...

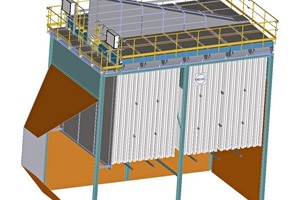

During the last few years they have made substantial investments at the headquarters in Krauschwitz (Saxony/Upper Lusatia). With more than 5200 m2 of indoor manufacturing area, the company has the optimum prerequisites to manufacture and finish machine almost all products with its technological equipment and a very high degree of in-house production depth (Fig. 1).

The products always correspond to the state of the art due to consistent further development. As a result, the launch of a very large emptying rotary airlock (with a rotor diameter of up to 2000 mm) was an enormous step forward as regards market acceptance in the cement industry, i.e. feeding moist and wearing raw materials to crusher/dryer combinations and materials to vertical roller mills. Consequently, even with a sticky feed, continuous conveying is ensured with simultaneous airtight sealing. Conveying equipment and filter plants as well as heat exchangers are efficient and resource-conserving solutions for various production processes (Fig. 2).

One of the last successful projects was the conversion of an ELEX ESP to a Kreisel bag filter for the dust collection of a rotary kiln. In December 2010 Kreisel GmbH & Co. KG received a corresponding order from a cement plant in Poland. The operator intended to burn also alternative fuels (domestic waste). The existing ESP would release too much residual dust after changing the fuels. Therefore, the task was to convert the existing ESP, maintaining the supporting structure of the casing and the discharge devices so as to meet the requirements of the German Clean Air Standards.

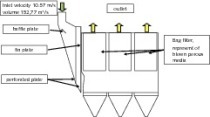

First the existing raw gas casing was recalculated statically taking into account the new loads (low pressure and weight of filter heads). The existing ESP casing was gutted (the electrodes were removed). The filter ceiling including electrical parts and rapping mechanism were also dismantled. The filter ceiling was stabilized with an intermediate frame and designed to take the filter heads. For the conversion of the ESP, Kreisel supplied 14 new filter heads in two rows with 2128 filter bags of 160 mm diameter x 6000 mm length, a radial fan and a fresh air damper. The existing dust discharge devices could be used further without any modifications. The entire conversion, including dismantling and erection, installation of the new clean gas pipeline and connection of the filter control system to the central plant control system in the central control room, was started early in April 2011 and took 20 days.

The plant was designed as a rotary kiln (E4) for cement. The raw gas volume flow amounts to max. 246,000 m3/h (in operation) at 160°C, and a raw gas dust content of 200-400 g/m3. The SO2 content varies between 10 and 20 mg/m3. The residual dust content is < 10 mg/Nm3 with a filter surface of 3206 m2 (14 filter heads). After 4 weeks of operation, the operating results clearly exceeded the expectations of the user. A very low compressed air consumption, a low filter pressure loss (Δp ~ 600-700 Pa) as well as a residual dust concentration clearly below 10 mg/m3 stp are very good results (Fig. 3).

The cleaning of the bag filter by delta P clearly prolongs the service life of the filter bags and the low filter pressure losses have clearly minimized the consumption of compressed air. The conversion of the existing ESP to bag filters reduced the modernization costs by almost half, compared to the installation of a new filter plant, due to maintaining the existing ESP casing, the supporting structure, the raw gas pipeline as well as the dust discharge system. The Polish Association for Ecological Technologies “Silesia” (Stowarzyszenie Technologii Ekologicznych “Silesia”) rated the conversion positively and underlined that more bag filters with these operating properties should be used in power plants and refuse incineration plants. This is only one example of the successfully implemented plant projects.

At present, the focus of research and development is on rotary valves with high wear protection (ceramic lining) and pressure-tight rotary air locks for drying plants. In the future Kreisel will increasingly become established as a supplier of complete systems for pneumatic handling installations. All essential components (amongst other things, also high pressure vessels and Kreisel dome valves) are available from their own manufacturing department. First these components are tested in the company’s own pilot plant and the optimum conveying parameters are determined.

The objective for the years to come will be to continue to deliver a proven technical product. “To successfully continue the company history will only be possible by permanent further development of the products and services with a clear focus on energy efficiency and resource conservation”, concludes Horst Meister.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.