ESP retrofit for Bagalkot cement

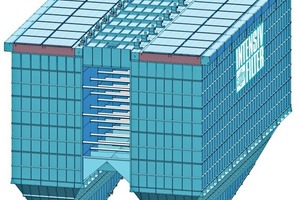

When a conversion of an ESP to a bag filter is necessary, 10 m fabric filter bags offer maximum air pollution prevention at lowest space requirements.

Retrofit of electrostatic precipitators into fabric filter

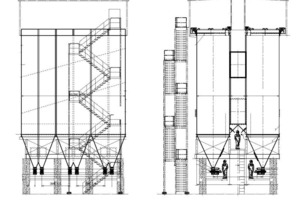

One of the cement manufacturers based in the federal state of Karnataka is Bagalkot Cement. They have produced cement already since 1948. Investments in a modern filter technology are evaluated by the cement manufacturer as a right measure for an environment-friendly cement production. In the cement plant the dust removal of the rotary kiln has been carried out for decades by an electrostatic precipitator. It is not able though to keep the low emission standards of 10 mg/m3 n.c. under all conditions (Tab. 2). That‘s why and because of too high dust loads during necessary start-up processes and rundowns, Bagalkot Cement decided to retrofit the electrostatic precipitator (Fig. 2) into a bag filter (Fig. 3). On top of this comes the striking distance of the cement plant to the city limit. The negative environmental influences on the welfare of the neighbourhood are put down by Bagalkot Cement with the retrofit into a bag filter.

Every filter retrofit is to be adapted very thoroughly to the dust removal standards and economic frame data. With the search for an adequate dust removal specialist the choice of Bagalkot Cement fell on Intensiv-Filter India. The following advantages of Intensiv-Filter bag filters were decisive:

Constant and less raw gas dust content, especially when using secondary fuels to comply with requirements of authorities.

The efficiency is not dependent on changing operating parameters.

The dust separation is not determined by water content or gas properties.

No CO trips for kiln de-dusting applications.

Online maintenance capabilities.

Simple access to the clean-gas-side.

Outlay for a conversion is considerably less than the cost of a new installation.

Upgrade time is reduced considerably by filter heads with variable filter head sizes and can be carried out during scheduled downtime.

filter bags of 8 m length and longer enable existing electrostatic filter housings to be used without increase of the floor space.

Conversion facilitated by experience

As in most cases of ESP conversions, the steps of this order are as following:

1. The new bag filter with new casing with compartments, hopper, intermediate ductwork and necessary dampers and inlet and outlet of each compartment will be installed.

2. The compartments will then be insulated on the clean-gas-side and equipped with pneumatic shut-off valves which are activated automatically as well as being externally accessible for maintenance purposes.

3. The clean gas side of the new bag filter will be connected at each side to the existing clean gas duct work and filter fan.

4. The bag filter will be supplied with a penthouse.

5. Installation of access doors, walkways and ladders as well as filter bags.

6. The dust discharge system will remain the same.

Reducing pressure drop

Continuous adjustment of tank pressure

Higher gas flow possible

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.