Successful commissioning of a ceramic rotary feeder at PPC Hercules

This article reports on the advantages of the ZSV-H Kreisel ceramic rotary feeder over screw pumps and on the successful commissioning of a ZSV-H for PPC Hercules in South Africa.

1 Introduction

The transport of fine bulk solids, such as cement, raw meal, fly ash or coal, usually takes place pneumatically over complicated conveying line routes. This means that the bulk material is transported by conveying air through a pipeline system. The friction that occurs between the bulk material and the pipeline wall and the vertical lift in the bulk material conveying lines causes a loss of pressure in the conveying air. Consequently, the conveying air for the product transport must be made available at a plant-specific pressure. The bulk material has to be fed into the air flow...

1 Introduction

The transport of fine bulk solids, such as cement, raw meal, fly ash or coal, usually takes place pneumatically over complicated conveying line routes. This means that the bulk material is transported by conveying air through a pipeline system. The friction that occurs between the bulk material and the pipeline wall and the vertical lift in the bulk material conveying lines causes a loss of pressure in the conveying air. Consequently, the conveying air for the product transport must be made available at a plant-specific pressure. The bulk material has to be fed into the air flow of the conveying line against this plant pressure. Different feed systems can be used for this purpose. Complicated pressure vessel systems or screw pumps were used in the past. For over half a decade these systems have been replaced by highly wear-resistant ZSV-H ceramic rotary feeders produced by Kreisel GmbH & Co. KG, Germany. The most important criterion for the use of the Kreisel ceramic rotary feeder is the energy saving during plant operation and the considerable wear resistance of the components.

PPC in South Africa chose a Kreisel ZSV-H 700 for their work in Hercules as the replacement for a screw pump to make a power consumption saving of 130 kW for driving the screw pump.

2 Plant description

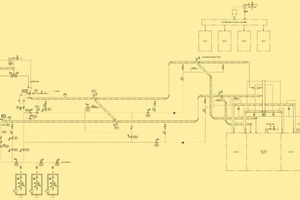

Figure 1 is a flow chart for a cement grinding plant. The Hercules PPC factory operates a vertical roller mill for grinding the cement. The cement is collected in the downstream baghouse. An output rotary feeder is placed under each of the two hoppers as well as a shut off valve below the baghouse. It doses the cement into an airslide that transports the material to the DV22 distributor.

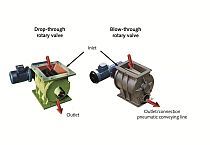

The airslide diverter feeds the two feeding system shown in Figure 2 for pneumatic conveying:

the Kreisel ceramic rotary feeder (Figure 2, on the right)

the standby screw pump (Figure 2, on the left)

The Duo-Cell silo and the packing plant are fed by the pneumatic conveying system. The Kreisel ZSV-H has been installed so that it can load all three receiving points. The pneumatic transport covers approximately 260 m with a vertical conveying height of 53 m. The conveying capacity is 150 t/h. The existing pressure generators can also be used by the ZSV-H operation. The ceramic rotary feeder and its feed hopper were fitted into the existing plant so that no modifications on the steel structure or the conveying line were necessary.

3 Commissioning of the Kreisel

ceramic rotary feeder

Kreisel invited the plant engineers from PPC to Germany in December 2014 to present the Kreisel ceramic rotary feeder. After detailed design discussions PPC decided to replace the screw pump by the Kreisel ceramic rotary feeder. The rotary feeder was installed after a delivery time of 5 months.

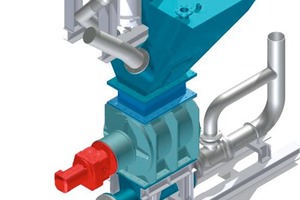

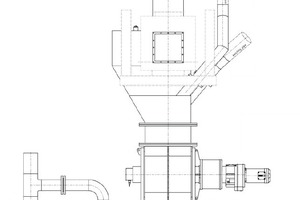

Kreisel engineered the integration of the Kreisel ZSV-H (Figure 3) into the existing plant configuration (Figure 4). It was possible to use the existing support structures of the screw pump for the assembly.

The existing screw pump was dismantled and the Kreisel ZSV-H was installed within a very short time frame. The project management was carried out so that the air lines of the pressure generators, the cement feed and the conveying pipeline could be optimally integrated into the technical process.

The erection and commissioning were supervised by Kreisel. The installation was followed by the commissioning in which the half-day cold commissioning was followed by the hot commissioning. The grinding plant was started at 100 t/h. After a short time the plant capacity was increased to 110 t/h and this capacity was kept constant overnight. Over the next two days of operation the mill output was adjusted to the expected conveying capacity of the ceramic rotary feeder of 150 t/h.

The conveying line back pressure settled to about 1.1 bar. The increase in mill output during the commissioning resulted in the evaluation that the ZSV-H could feed at least 180 t/h of cement into the existing conveying pipeline. Kreisel achieved the maximum degree of filling by further development of the inlet geometry of the leakage air collector to improve the flow. The leakage air is carefully separated to achieve the optimum constant capacity.

4 Comparison of the Kreisel

ceramic rotary feeder with a screw pump

With the Kreisel ZSV-H, Kreisel GmbH & Co.KG has a feeder that meets current customer demands for high precision. After decades of development and optimization the rotary feeders from Kreisel are known across all industries for their high quality of manufacture and their reliability. The ceramic lining of the product contact surfaces allows this traditional product to be used as a feeder in pneumatic conveying systems with abrasive materials.

For a long time the wear caused by flow had been the reason why the rotary feeders were not used as feeders for abrasive materials. The use of the latest ceramic elements means that the necessary requirements for the feeders are now far exceeded.

The Kreisel ZSV-H can not only contribute its outstanding properties to the pneumatic conveying systems but is also better than the established input systems with regard to service life, maintenance and spare parts requirements.

The argument that was often cited in the past for a high energy loss because of the escaping leakage air in the feed area has been countered by the use of side plates at the rotor and by the precision of the very small gaps. Solid construction and grinding of the ceramic elements guarantee the small gaps and define predictable quantities of leakage air. These compare favourably with the energy loss of the nozzles used in other systems.

Now that the Kreisel ZSV-H had met the customer requirements for reliability and energy efficiency it was still necessary to verify the integration.

Here again the Kreisel ceramic rotary feeders can reveal their potential thorough their small space requirement and low weight, and have no problem with satisfying the safety officers. Regulated space conditions and the static limits of the existing steel structure for loads and vibration severely limited the plant manufacturer’s room for manoeuvre. This is why it is only with the rotary feeder that the customer’s chosen transfer points could be implemented.

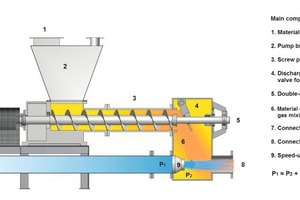

The functioning of a screw pump is explained briefly with the aid of the schematic diagram (Figure 5) so that the Kreisel ZSV-H can be compared with a screw pump.

The bulk material falls through the inlet (1) in the pump surge bin (2). This is used to draw off the sealing air and the air displaced from the bulk material. The bulk material is picked up and transported to the outlet by the high speed compression screw (1000 rpm).

The bulk material is heavily compressed. This compression is assisted by a check flap (4). The compression produces a high-density plug of bulk material that provides a seal against the pressure in the conveying pipeline. The solid bulk plug then drops into the outlet of the screw pump where it is picked up by the conveying air and transported into the conveying pipeline. The conveying air has to pass through a nozzle or, depending on the design, several nozzles in the outlet housing. This nozzle produces a pressure drop of about 0.30 bar and serves to accelerate the conveying air and the bulk material.

The differences between Kreisel Ceramic feeders and screw pump are as follows.

4.1 Foreign bodies

If foreign bodies, such as the remains of grinding balls, are introduced accidentally with the bulk material then they must pass through the feeder. Using the example at the PPC the screw pump has a peripheral speed of > 15 m/s, whereas the rotary feeder works with < 0.70 m/s. In screw pumps this can lead to breakage of the wear bushes or the end flight of the screw. In the rotary feeder it is unlikely that these foreign bodies will meet the rotor in such a position that they cause jamming, and even jamming does not normally damage the rotary feeder.

4.2 Properties of the bulk material

The properties of the bulk material, such as fineness (Blaine), grain size distribution, bulk density and moisture, are necessary for dimensioning a screw pump. In addition to the back pressure in the conveying pipeline these parameters affect the dimensioning of the drive motor. If these properties are changed by fluctuating processing conditions, this can lead to failure of the screw pump. The results are loss of capacity, motor overloading and sealing problems. Bulk material that is too fine or too coarse can only be fed at low pressures (<0.5 bar) because the plug formation is inadequate.

For the design of the rotary feeder, however, only the density of the bulk material is crucial. The drive is determined exclusively by the dimensioning of the rotary feeder. A 5.5 kW motor is installed for the rotary feeder at the PPC plant. This draws a power of less than 1 kW during operation.

4.3 Grinding aid

Grinding aids are used to reduce the energy input during grinding. However, these greatly change the conveying and fluidizing behaviour of bulk materials because they affect the intermolecular forces. The experience of recent years has shown that grinding aids can also have a strong influence on the compression behaviour of the bulk materials. This reduced the capacity of the screw pumps by 30 %. In this connection the 132 kW motor that was installed proved to be under-dimensioned. The rotary feeder does not generate any compression of the bulk material for sealing purposes so the grinding aid has no negative effect on the conveying and drive capacity of the rotary feeder.

4.4 Overloading of the inlet area

If the material dosing to the screw pump is irregular and the screw pump is operated close to the capacity limit, then overloading of the inlet area reduces the capacity. If the pump surge bin fills with bulk material then the compressed air from the plug can no longer be discharged at the inlet. The air is transported through the system by the plug. The plug becomes unstable and can no longer form a seal against the existing conveying line pressure. This causes a reduction in capacity. The design of the inlet to the rotary feeder separates the dust removal area from the inlet area. Overfilling of the inlet therefore leads primarily to an increase in capacity rather than a reduction.

4.5 Wear during operation at reduced load

If the mass flow of bulk material to the screw pump is too low then the requisite sealing plug cannot form properly. The plug breaks down and the conveying air flows into the inlet area at high speed. This acts on the screw like a sand blast nozzle while in the ceramic-lined rotary feeder this does not have a negative effect. There would also be the option of reducing the wear by lowering the rotational speed.

4.6 Energy consumption during operation

at reduced load

When the rotary feeder is the input device then, if the mass flow drops, the requisite conveying line pressure also drops. If the back pressure in the conveying line drops then the motor current consumption of the pressure generator will drop too. However, this situation with screw pump conveying is different. In this case the influencing component is the nozzle (Figure 6, item 9) in the outlet housing. As with any nozzle the pressure loss increases with increasing flow rate. If the delivery line pressure in the screw pump conveying system drops then the operating volume of the conveying air will increase. This leads to an increase in velocity. The pressure before the nozzle falls significantly but the pressure after the nozzle falls only slightly. Operation of screw pumps at reduced load is therefore very unfavourable from the energy point of view.

4.7 Wear reduction by reducing the speed

The wear on the ceramic rotary feeder depends on factors such as hardness and shape of the bulk material, the pressure difference across the feeder and the rotational speed of the feeder. The wear can be reduced by adjusting the rotary speed to suit the respective conveying bulk material mass flow. This is not possible with screw pumps. The high rotational speed of the screw shaft is required to fulfil the sealing function.

4.8 Influence of the back pressure

on the pump motor

The size of motor for the screw pump is almost linearly dependent on the back pressure in the conveying line. Even at average conveying capacities this results in motor sizes of 30 kW to 250 kW. On the other hand the motor for the rotary feeder is determined only by the size of the rotary feeder. In a rotary feeder, the motor for 180 t/h of raw meal, for example, has a rating of 5.5 kW and during operation it uses less than 1 kW.

4.9 Grain destruction

The high compression of the bulk material due to the relative movement of the screw pump leads to destruction of the grains, which, depending on the industry (e.g. the alumina industry), shall be avoided. Kreisel ceramic rotary feeders cause no appreciable grain destruction.

4.10 Motor control centre (MCC)

Thanks to the small drive motor for the rotary feeder and the smaller pressure generator motor the MCC can be also made considerably smaller and therefore less expensive. These costs can amount to tens of thousands of euros.

4.11 Commissioning

As already mentioned in Sections 4.2 and 4.3, the screw pump reacts to various system parameters. Multiple modifications are necessary to achieve the correct screw pump configuration during the commissioning while taking the points in 4.2 and 4.3 into account. Screw pitch, plug length, nozzle diameter and return flap adjustment must be determined in time-consuming conversion processes. The rotary feeder, however, does not respond to these parameters. A rotary feeder can usually be brought into operation in one to two days.

4.12 Space requirement

The low space requirements of the ZSVH can be mentioned as the final advantage. As can be seen from Figure 2 and Figure 7, the ZSV-H can be adapted to suit virtually all local conditions. A rotary feeder can be installed anywhere where there is space for a screw pump with its pump surge bin. At PPC Hercules, for example, the screw pump is 4500 mm long while the Kreisel ceramic rotary feeder requires only 2150 mm including motor.

4.13 Leakage air

Because of the prevailing pressure differences the leakage air flow in rotary feeders is directed against the flow of bulk material. This lies between 5% and 12% of the total quantity of conveying air. It is discharged via the dust collector. At PPC the leakage air accounts for 6.4 % of the total compressor power while the energy loss caused by the screw pump nozzle is 15.5 %.

4.14 Capacity of the Cerafeed ZSV-H

Depending on the length of the rotary feeder the conveying capacity of the ZSV-H is between 0.3 and 250 m³/h. Conveying line pressures of up to 2.0 bar can be applied, depending on the bulk material.

5 Energy balance using the example

of PPC Hercules

PPC operates various pneumatic conveying systems at the Hercules plant. Two of them are used to transport cement from the grinding plant to the receiving silos. The cement was fed into the conveying lines by screw pumps. Repeated problems, loss of capacity and high energy consumption gave PPC reason to bring about some technical changes. PPC settled for the latest state of the art – ceramic rotary feeders from Kreisel Germany. Table 1 shows the system parameters of the pneumatic conveying plant with a screw pump as the feed component.

The data records show a maximum stable conveying capacity of 100 – 130 t/h, depending on the type of cement. In addition to the inadequate conveying capacity there were screw pump failures for various reasons. The operation was disrupted by overfilling and motor failures.

In September 2015 the standby conveying screw pump was replaced by a Kreisel ZSV-H, size 700. It was commissioned within two days. A stable conveying capacity of 140 t/h was obtained during the commissioning. The plant capacity was increased to 175 t/h by optimizing the grinding and filter processes and it was found that the Kreisel ZSV-H had not yet reached its limits. So far the plant has been in continuous operation for four months.

Figure 2 shows the plant layout after conversion to the Kreisel ZSV-H. The inlet was adapted to allow continued use of the support structure for the supporting the screw pump This resulted in very short conversion times.

The driving power of the rotary feeder is measured continuously by the customer. Due to the special bearings the rotary feeder operates at a power of less than 1 kW.

Replacement of the screw pump by a ceramic rotary feeder has saved a significant proportion of the energy costs of pneumatic conveying. As a result, the return on investment is less than one year.

6 Summary

By replacing the screw pump with a Kreisel ceramic rotary valve PPC was able to increase its cement transport capacity to at least 175 t/h. Other advantages are a stable, reliable pneumatic conveying system with a very low energy consumption. An annual amount of energy saving of approximately € 100 000 has been achieved. This is one of more than two dozen successful projects involving a Kreisel ceramic rotary feeder. Meanwhile, PPC has ordered more ZSV-Hs to replace screw pumps in South Africa. Kreisel and PPC are jointly investigating the behaviour and lifetime of the rotary valve.

//www.kreisel.eu" target="_blank" >www.kreisel.eu:www.kreisel.eu

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.