Logistics between cement plants and distribution

centers is automated – at least sometimes

Summary: Cement has to be shipped from the plant to several distribution centers. In these centers the cement powder is mixed with water, sand and gravel, processed to concrete to be distributed with trucks. The demand at every center is quite volatile since it is the point of sale to the end customer. The personnel on site usually do the reordering of new material. To meet the needs of the distribution centers the plant has to be quite flexible and needs a high number of trucks for distribution of new cement powder to the centers. Orbit Logistics creates a Supply Chain Management solution that fits into this environment and helps to save time and money and to reduce transport to protect the environment.

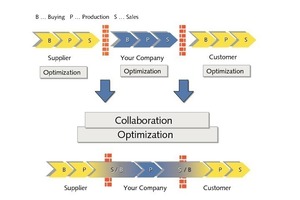

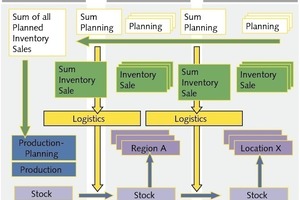

Like no other industry, the cement industry has to cope with high volumes and low prices. This means that logistics is a key to success as it has a great influence on productivity and profit.Poor or even non-optimized logistics can consume the whole profit of a certain product. The flow of information and data has to be managed company-wide. Isolated solutions do not contribute to the desired success. (Fig. 1).

As it is extremely ineffective to transport ready-mixed concrete over long distances, the cement producers usually build up distribution centers. The distribution centers...

Like no other industry, the cement industry has to cope with high volumes and low prices. This means that logistics is a key to success as it has a great influence on productivity and profit.Poor or even non-optimized logistics can consume the whole profit of a certain product. The flow of information and data has to be managed company-wide. Isolated solutions do not contribute to the desired success. (Fig. 1).

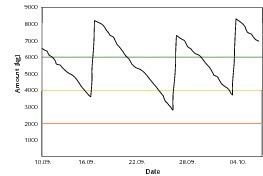

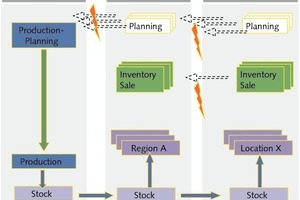

As it is extremely ineffective to transport ready-mixed concrete over long distances, the cement producers usually build up distribution centers. The distribution centers are supplied directly from the cement plants and mix the concrete on site to the desired product for the customers. This reduces the unnecessary transport of sand and gravel over long distances and always ensures an acceptably good quality of the concrete. The replenishment of the cement silos represents the biggest logistics challenge in this process. There are no other storage locations between the cement plant and the distribution sites, which means that all changes in customer’s demand have a direct impact on the plant. On the one hand this excludes the possibility of the much feared bullwhip effect, on the other hand it requires great flexibility of the plant to cope with changing customer demands (Fig. 2). Therefore it is essential for the logistic planning to have a good overview of what is in stock at the distribution sites right now. Furthermore, the PC systems of the different companies or locations are quite often not interconnected or use incompatible data formats that prohibit direct data exchange. Manual data transmission takes time and often creates errors during transmission. (Fig. 3).

Very often stocktaking is done manually. An automated system has a lot of advantages, especially if a great number of distribution centers or silos have to be managed. It is more or less impossible to collect all data manually without making an error now and then. Of course that does not happen on purpose, it can be an unclear fax transmission, an e-mail that got lost or just a misunderstanding during a phone call due to noise from a nearby machine.

A database that automatically collects silo levels in cyclic periods and populates the data into Enterprise Resource Planning systems, short ERP systems, can increase productivity and save time and money. Systems that deliver such functionality are called Vendor Managed Inventory systems, or short VMI systems.

VMI systems actively help the material planner to carry out his work. Depending on the integration level into the ERP system, the scope ranges from simply displaying silo levels up to a full integration where orders or order suggestions are placed fully automatically. The orders can be created either based on actual stock and alarm levels or can be based on forecast data that is permanently checked against actual stock levels. Reliable forecast requires that end customers place orders ahead of time with the distribution centers.

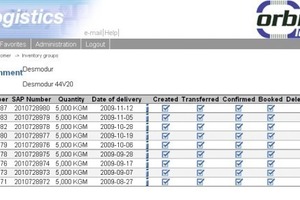

The implementation of a VMI system is done step by step, whereas the single steps are based on earlier ones. If not already in place, the silos to be monitored are equipped with level instrumentation (Fig. 4). There are different radar technologies available that work with cement powder. These radars are customized to fit the individual circumstances at the silos. During the next step a Remote Terminal Unit, or short RTU, is installed close to the monitored silos. The RTU is used to communicate with the VMI database. Communication is usually done via analog land line, Internet or cell phone networks. As soon as the data is available in the VMI database a huge number of possible analytics can be used with the numbers. The outcome is an advanced inventory management. The fast access of the data through the Internet ensures that everybody who has the need for it can be up to date about orders and stock levels at any time of the day (Fig. 5).

The material planners can easily get an overview of the stock levels in the silos for which they are responsible. Ideally the silos are displayed next to each other in an easy to understand graphical presentation. The next step for integration is the interface between the VMI database and the ERP system of the cement supplier. The interface allows fully automatic ordering of new material or “One-Click” orders made by the material planner. If the decision making should be done on site of the silos; the personnel on site can very comfortably trigger orders using the website of the VMI application.

Today, most VMI solutions are Application Service Provider solutions, also called ASP or Hosted Solutions. With the business models the whole service is outsourced. The user accesses the data through a website. For the cement company the whole development and maintenance of installed programs is no longer necessary. An Internet-enabled PC is sufficient. The whole infrastructure and service is delivered by the service provider. This solution is also beneficial in case more than two companies are involved in the process and an independent party – the service provider – can guarantee data security for all stakeholders. Such a customized turnkey solution for example is offered by the Orbit Logistics AG with subsidiaries in Germany, USA, Brazil, and China. Orbit Logistics offers solutions for bulk and packaged goods in the B2B market. The Orbit Logistics’ VMI package has a lot of advantages and can be used in diverse fields of applications.

The level measurement in the first place guarantees an accurate and safe monitoring of the stock level. Guessing, knocking, or even the daily climb on to the silo is history. All inventory data is available for everybody at any time without the assistance of a single employee. The material planner can work with real up-to-date stock levels. Incorrect or over-deliveries can be avoided. The VMI system proactively makes order suggestions and actually places the orders in the ERP system. Orders that are made too late are practically impossible and costly rush orders are avoided. Errors during the order process, e. g. transposed digits, can no longer occur because of the predefined automatic ordering process. Entering orders is easier and automated, which results in enormous cost savings during the order management. The paperless office comes a little closer.

The improved information management not only helps with the administration, it also makes it easier to schedule truck routes, since already when the truck leaves the plant one can be sure that the load will fit into the silo at the distribution center. Waiting times at the distribution center can be minimized and rush hours or late night trips can be avoided which results in lower logistics costs.

A lot more accurate prognoses for the cement production can be given, as all stock levels at all selling points are available and the demand of the near future can be easily calculated. Production stops, e.g. for maintenance, can be planned more accurately as the required amount of material is known. While production runs normally, the stock levels can be optimized to reduce fixed capital. If there is a planned production stillstand the stock levels can be increased to ensure that demand can be satisfied.

An effective Supply-Chain-Automation starts with silo monitoring at the distribution centers. The aim of effective Supply Chain Management is to improve the supply chain as regards quality, time and costs (Fig. 6). This makes earlier and more accurate orders possible, which in return results in better planned and optimized truck routes. Stock outs are avoided and heavy traffic can be reduced. Production plans for the cement will be based on real data, not just wage forecasts. The free flow of information in the logistics chain increases profit, reduces errors, and increases the service level at the selling points. The costs for an integrated Supply-Chain-Automation for the cement industry range between five and ten Euros per day and silo.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.